Preparation method of sample for characterizing element distribution uniformity

A technology for element distribution and sample preparation, applied in electrical components, analytical materials, material analysis using wave/particle radiation, etc., which can solve the problem of low resolution, insufficient characterization of bulk element uniformity, and inability to accurately judge element distribution uniformity. To solve problems such as properties, to achieve the effect of simple and convenient preparation method, improve preparation efficiency and section quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] According to the present invention, a sample preparation method for characterizing the distribution uniformity of positive electrode material elements is provided, the method comprising:

[0027] Step 1, preparing the positive electrode material and preparing the positive electrode sheet.

[0028] In the present invention, in the field of lithium-ion batteries, the cathode material plays a key role in the electrochemical performance of the lithium-ion battery. Usually, the cathode material is obtained by dry mixing for element doping or coating, and the doping or coating of elements The distribution uniformity in the cathode material has an important influence on the electrochemical performance of the cathode material.

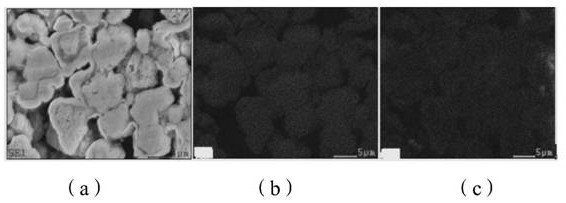

[0029] In the present invention, the distribution uniformity of the bulk phase elements in the positive electrode material can be obtained by making the positive electrode material into a pole piece, and cutting the pole piece, and obtaining the element...

Embodiment 1

[0066] Weigh 6.25g of binder PVDF and disperse it into 2.4g of N-methylpyrrolidone, then weigh 9.5g of nickel-cobalt-manganese cathode material and add it to the above solution, and stir evenly to obtain a slurry;

[0067] Apply the slurry to the aluminum foil by an electric coater, and place it in a 60°C oven to dry to obtain the positive electrode sheet, which is set aside;

[0068] Cut the positive pole piece into a square pole piece of 8*8cm;

[0069] Fix the square pole piece on the sample table fixture, and use liquid nitrogen to control the temperature of the sample table to 25°C to balance the sudden rise in the cavity temperature during cutting;

[0070] Three argon ion beams are used to cut the positive pole piece, the middle ion beam is perpendicular to the positive pole piece, and the other two beams are located on both sides of the middle ion beam, forming an angle of 60° with the middle ion beam, and adjusting the appropriate Ar gas flow ( 0-1), first set the vo...

Embodiment 2

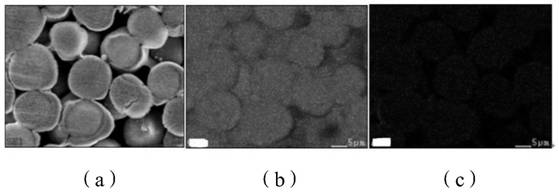

[0074] Weigh 1.5g of binder and disperse it into 2.9g of N-methylpyrrolidone, then add 9.88g of lithium cobaltate positive electrode material into the above solution, and stir to obtain a slurry;

[0075] The slurry is evenly coated on the aluminum foil by an electric coater, and then dried in an oven at 60°C to obtain the positive electrode sheet, which is set aside;

[0076] Cut the positive pole piece into a disc with a diameter of 15mm, and set aside;

[0077] Fix the wafer on the sample stage fixture, and control the temperature of the sample stage at 25°C to balance the sudden increase in the chamber temperature during cutting.

[0078] Three argon ion beams are used to cut the positive pole piece, the middle ion beam is perpendicular to the positive pole piece, and the other two beams are located on both sides of the middle ion beam, forming an angle of 60° with the middle ion beam, and adjusting the appropriate Ar gas flow ( 0-1), first set the voltage 4kV, grinding t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com