Integral bearing mechanism for ball screw

An integral bearing and ball screw technology, used in metal processing machinery parts, metal processing, metal processing equipment, etc., can solve the problem of temperature rise and thermal deformation increase, heat generation, ball screw rotation accuracy, rigidity, anti-vibration Reduce cutting performance and other problems, to achieve the effect of high load and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0025] It should be understood that terms such as "having", "comprising" and "including" as used herein do not entail the presence or addition of one or more other elements or combinations thereof.

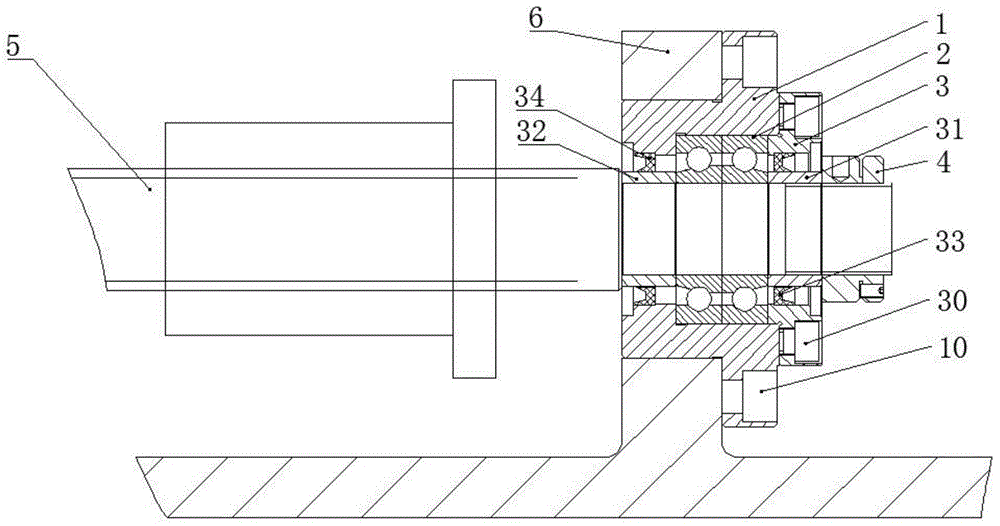

[0026] figure 1 An implementation form according to the present invention is shown, which includes:

[0027] Screw rod 5, which is a cylindrical rod-shaped structure, the end of the screw rod 5 is provided with a shaft shoulder, and the shaft shoulder is provided with a threaded portion;

[0028] The flanged bearing sleeve 1 is a combined structure of a cylinder and a flange. The flanged bearing sleeve 1 has a stepped through hole inside, and the stepped through hole is composed of a large and a small round hole. The large and small round holes are coaxially connected, the larg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com