Manufacturing technology of linear electric machine traction laminated induction board

A linear motor and manufacturing process technology, applied in the manufacture of motor generators, electrical components, electromechanical devices, etc., can solve the problems of many broken seams, large air gaps in linear motors, and increased production costs, and achieve the elimination of broken seams and gaps, Effect of reducing excitation current and reducing eddy current loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

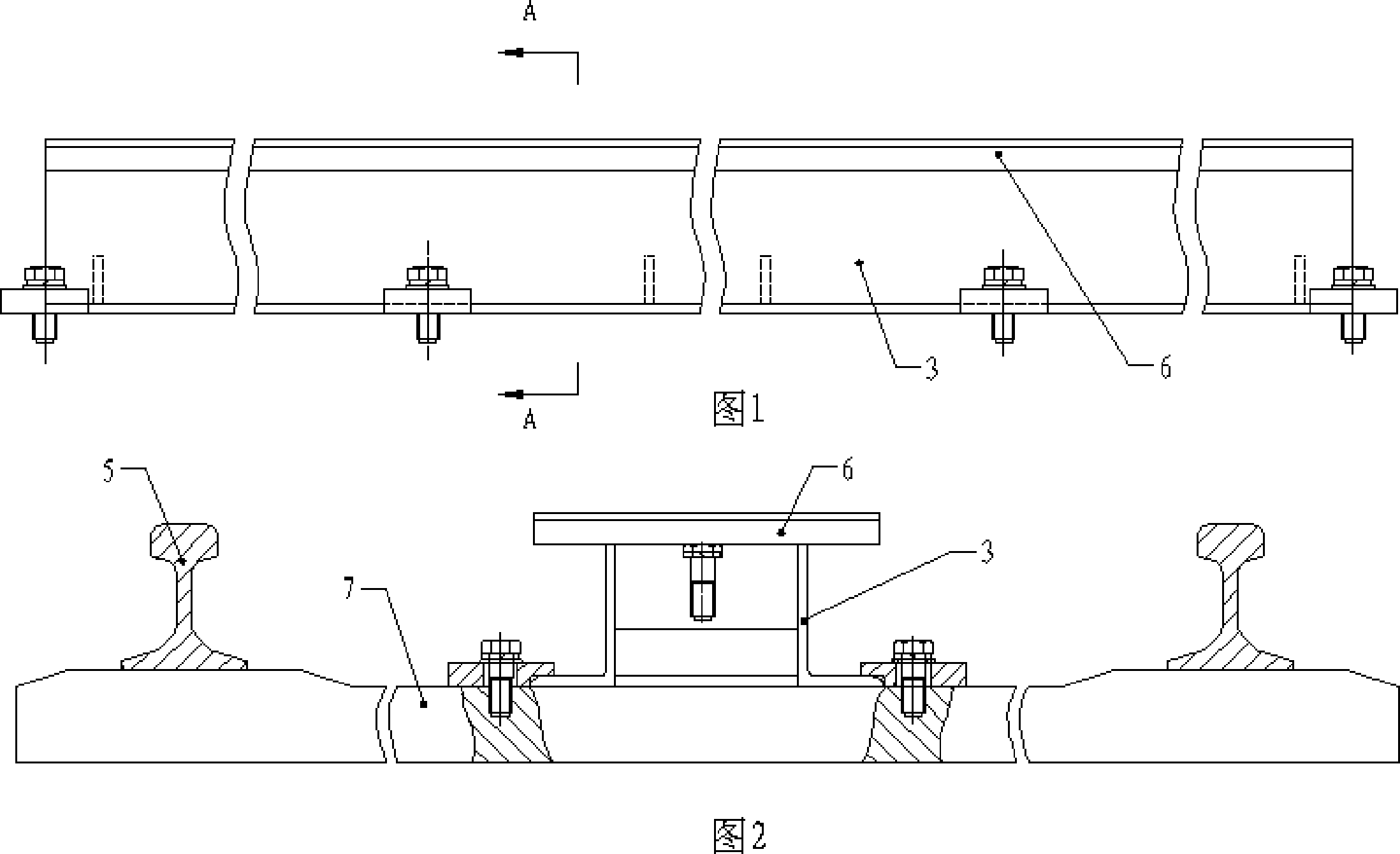

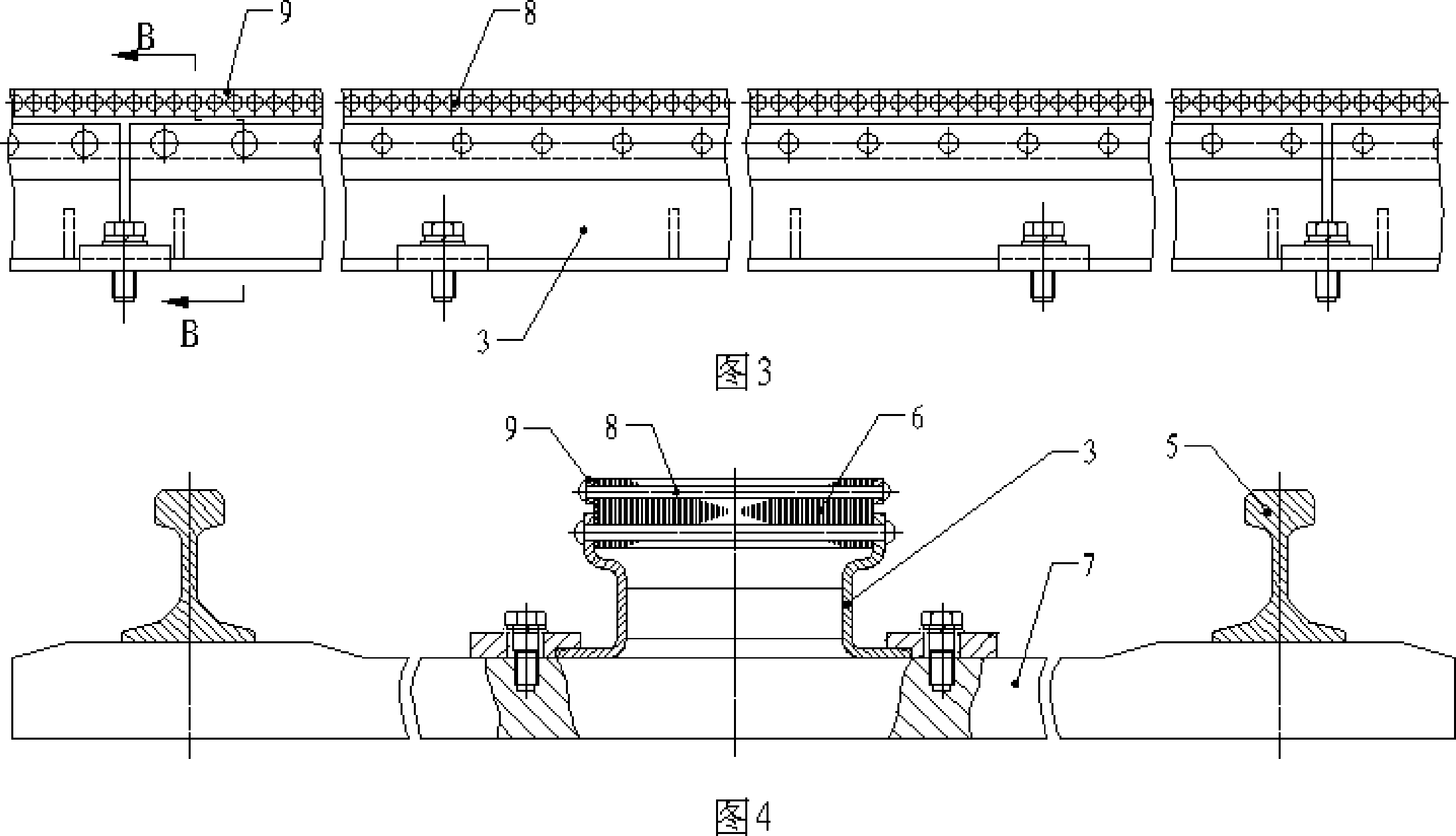

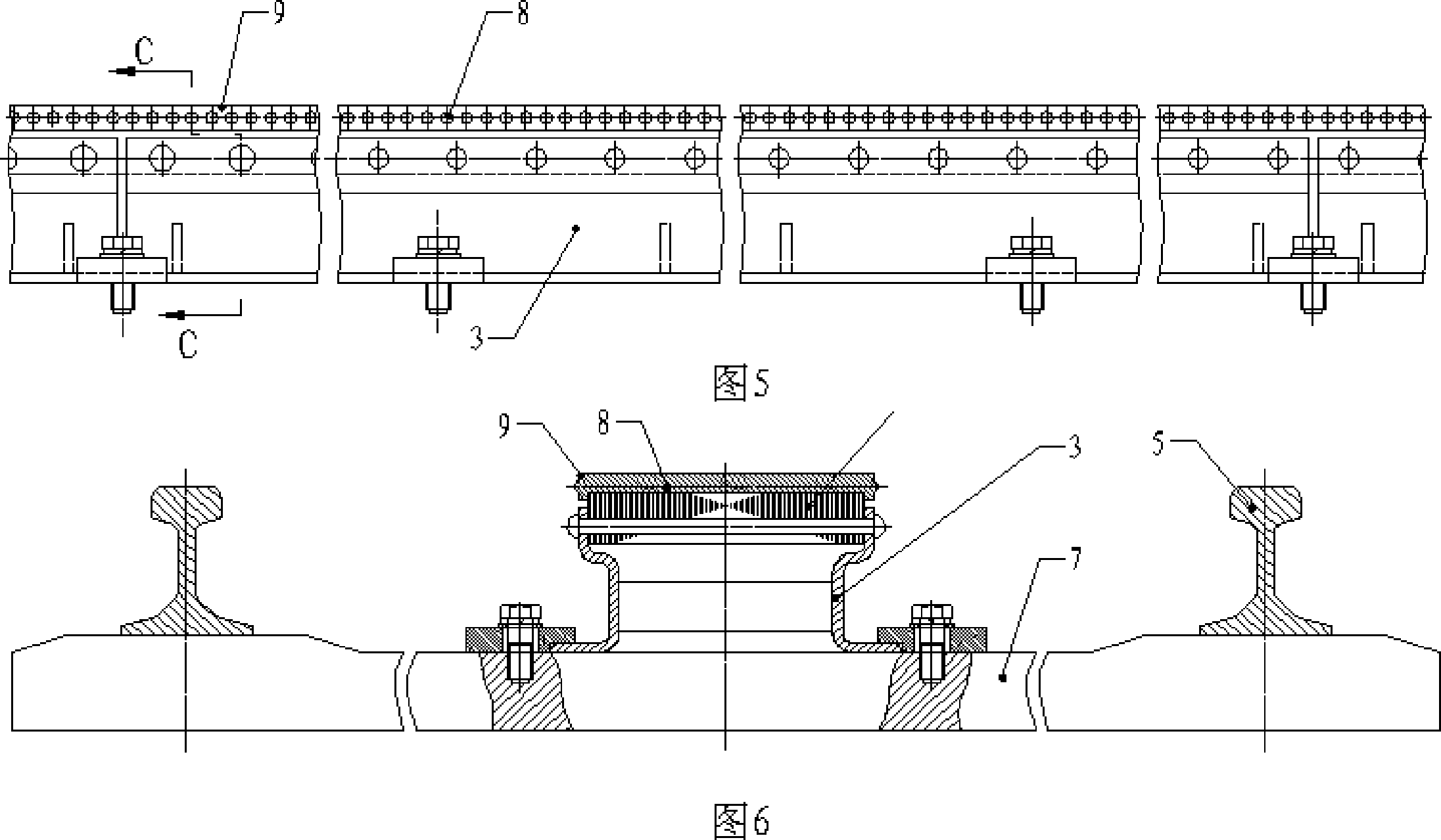

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0030] As shown in Figures 3 to 11, the manufacturing process of the linear motor traction laminated induction plate of the present invention includes the following steps:

[0031] a. Cut the thin steel plate into a narrow steel strip, and make two rows of holes on the narrow steel strip at intervals along its length direction to make a lamination 1, the upper row is the secondary coil hole 2, and the lower row is for the installation support frame 3 Mounting hole 4; material can adopt the electrical steel plate of coiling without insulating layer, as the silicon steel plate coiled material of 0.5 millimeter thickness, and its length has the length of a roll of steel plate, and its width is determined by the electrical property and the mechanical property of linear motor secondary. The lamination 1 can be finished in the factory, and rolled into a disc ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com