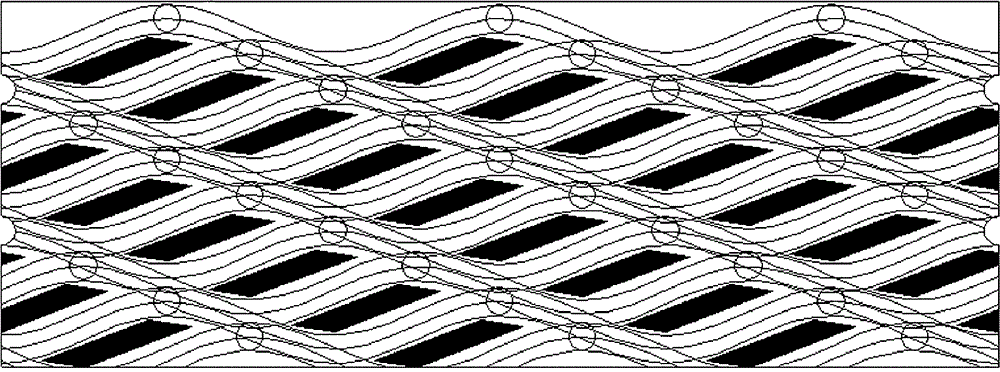

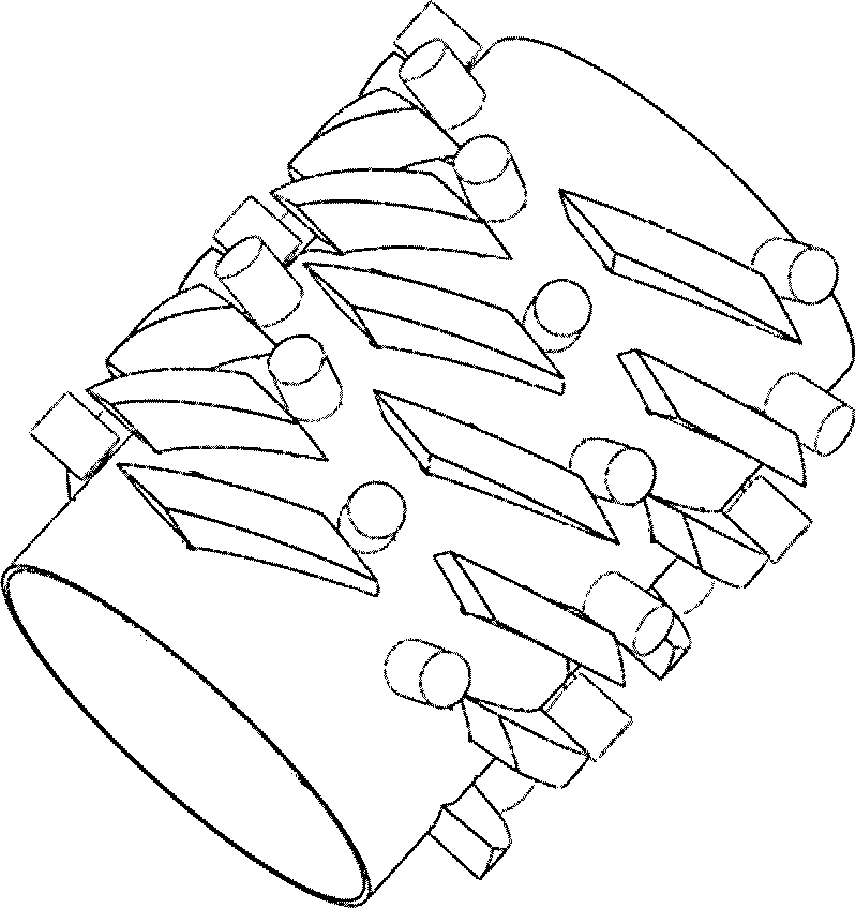

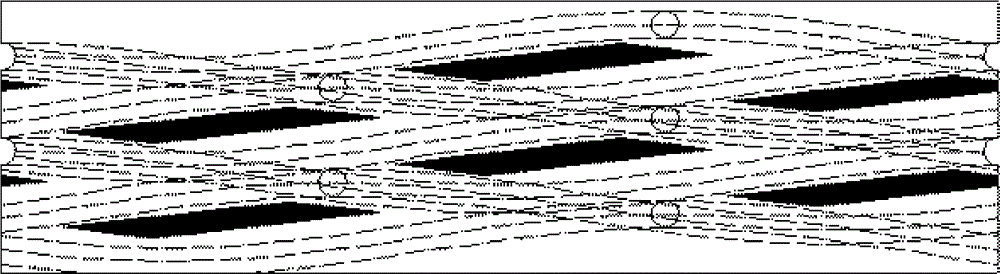

Reciprocating-type single screw pin extruder with one-cycle rotation for three times reciprocating and high efficiency mixing element

A reciprocating single-screw technology, applied in the field of new reciprocating single-screw pin extruder and its high-efficiency mixing components, can solve the problems of no industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The movement of screw rod of the present invention can be by such as Figure 7 shown in the principle to drive. Shaft 1 is the input shaft, the gear 3 on it drives the gear 4 on the intermediate shaft 2, the gear 5 on the shaft 2 drives the gear 6 on the shaft 7, the bevel gear 8 on the output shaft 7 is connected with the gear 6, and the driving shaft 7 rotates , The shaft 7 is connected with the gear 6 and the bevel gear 8 by a sliding key, and the gear 6 and the bevel gear 8 can slide axially on the shaft 7 relative to each other. The vertical shaft 11 and the vertical shaft 12 are arranged symmetrically up and down, on which bevel gears 9 and 10 with the same geometric shape are installed and meshed with the bevel gear 8 at the same time, and the bevel gear 8 drives the bevel gears 9 and 10 to rotate, vertical Cranks 13 and 14 are arranged on the shaft 11 and the vertical shaft 12, respectively drive the movement of the connecting rod 15 and the connecting rod 16, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com