Man carrying seat for boat

A seat and marine technology, applied in the field of manned safety seats for large bulk carriers, can solve the problems of low work efficiency, poor safety, and the inability of staff to get on and off the cabin normally, so as to save costs, ensure personnel safety, and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

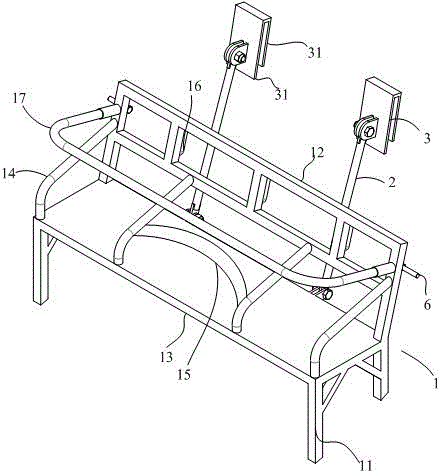

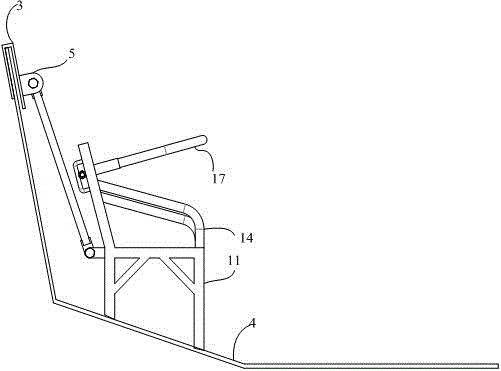

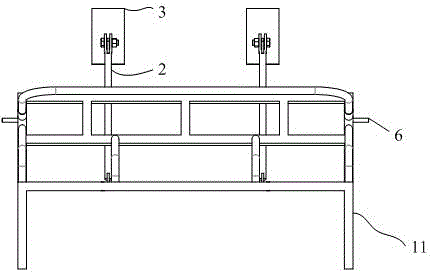

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

[0023] see Figure 1-Figure 5 , the present invention is an embodiment of a marine passenger seat, including a seat 1, a connecting piece 2 and a clamping piece 3; the seat 1 includes a seat leg 11, and the seat leg 11 is vertically arranged on the Below the seat 1, the height of the front leg of the seat leg 11 is greater than that of the rear leg;

[0024] Specifically, the marine manned seat in this embodiment is mainly matched with the grab bucket 4. The grab bucket 4 can be the grab bucket of the door machine or the unloading bucket of the ship unloader. The inner wall of the grab bucket 4 is semicircular arc-shaped, and the seat 1. Cooperate with the grab bucket 4 when in use, and use the grab bucket 4 to move up and down when grabbing goods, driving the up and down movement of the seat 1, so that people can go up and down the cabin normally when the inner cabin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com