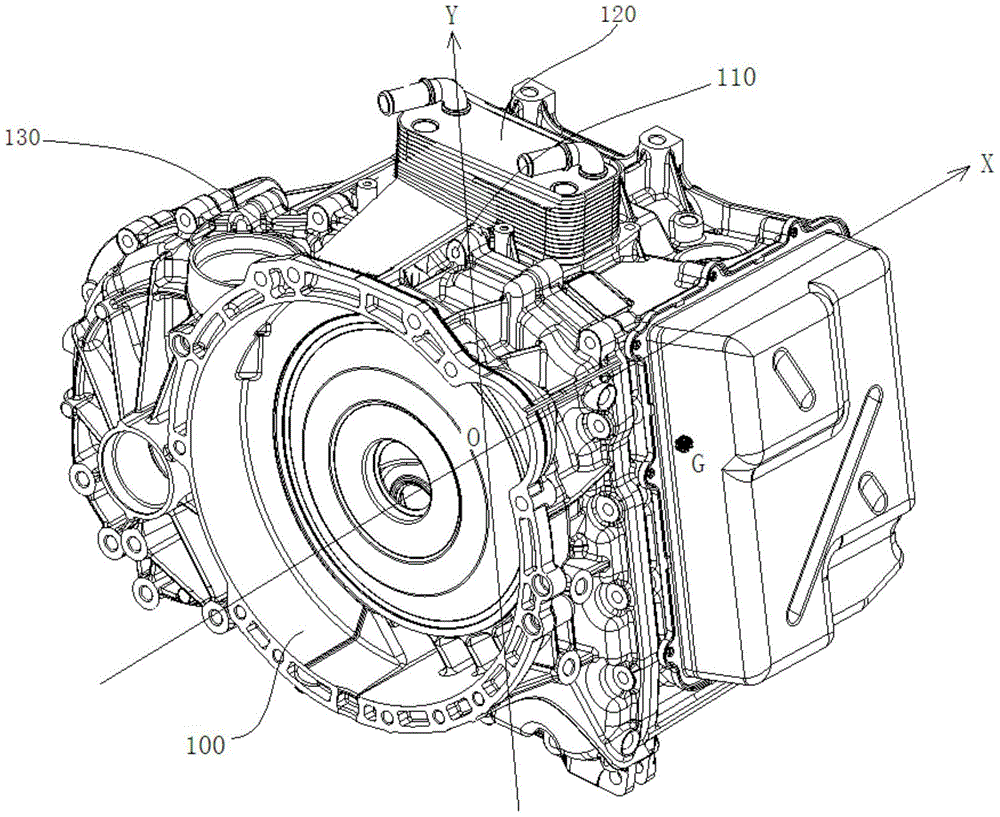

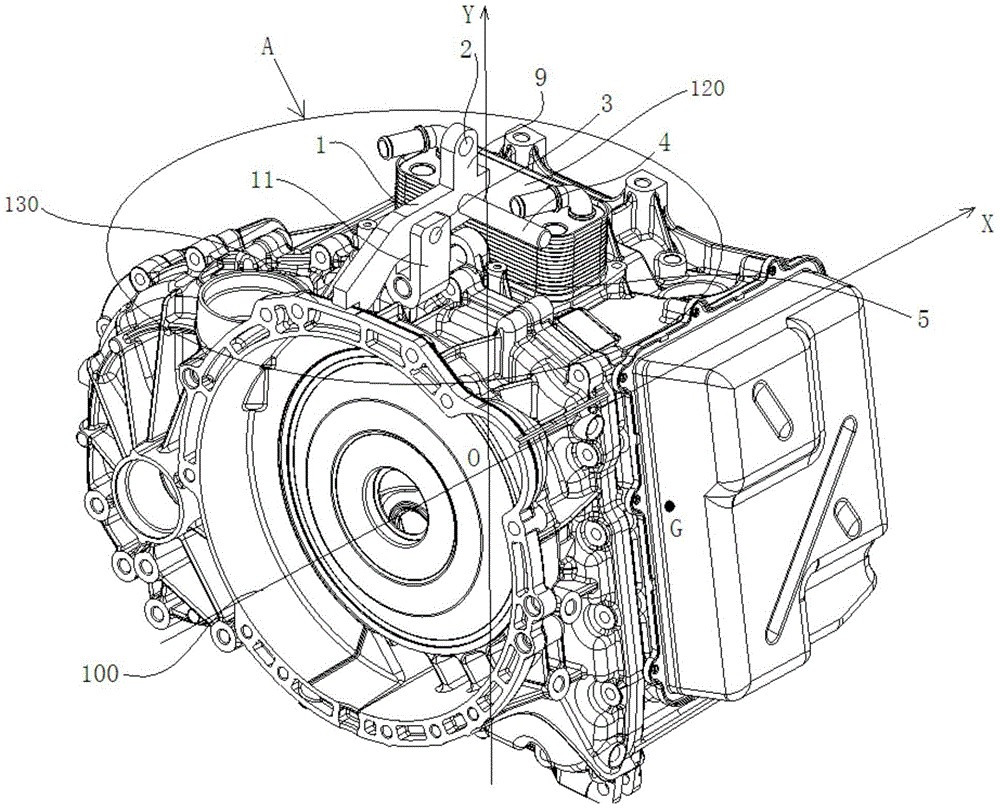

Transmission quick-loading spreader and transmission lifting structure

A gearbox and quick-installation technology, which is applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of unstable hoisting and the inability of the gearbox to be directly installed in place, and achieve the effect of improving versatility and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

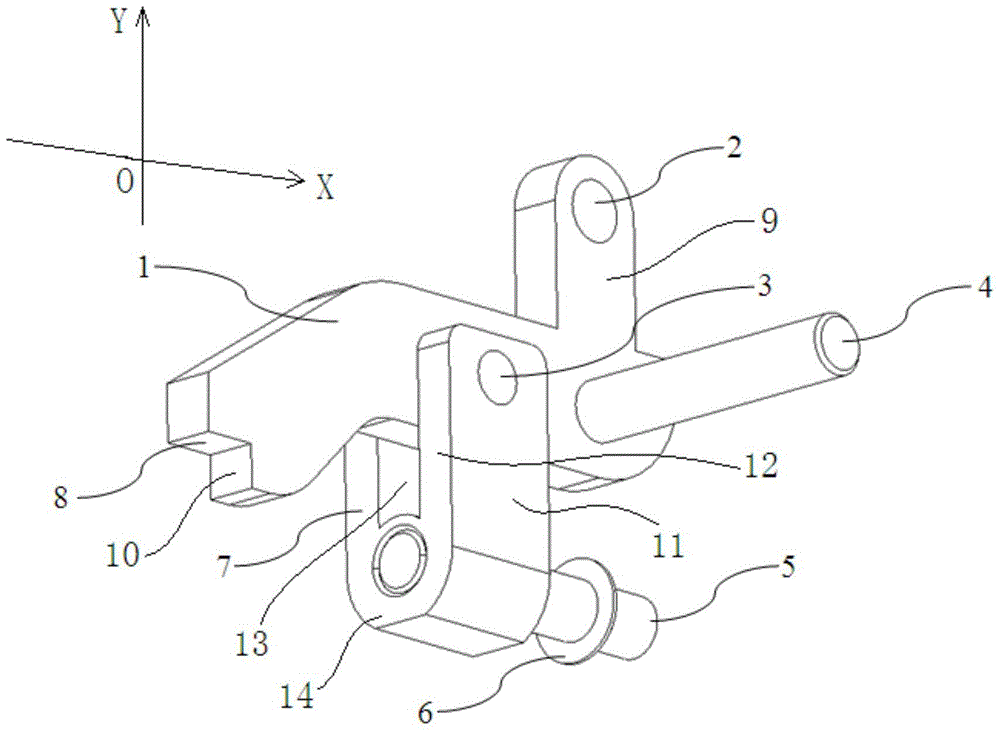

[0023] refer to figure 2 , the gearbox quick installation hanger in this embodiment includes four main parts: a cantilever 1 , a U-shaped support 11 , a rotating pin 3 , and a lifting pin 5 . In the X direction, one end of the cantilever 1 has a pressing surface 8 perpendicular to the Y direction and a thrust surface 10 perpendicular to the pressing surface 8 and perpendicular to the X direction, so that the cantilever 1 has a pawl shape, and the other end has a hoisting mechanism 2 . More specifically, in this embodiment, the hoisting mechanism 2 is a hoisting hole opened on the auxiliary cantilever 9, and the auxiliary cantilever 9 and the cantilever 1 are integral components, but in other optional embodiments, a common hoisting ring can also be used. , threaded rod and other devices are installed on the cantilever 1 as a lifting mechanism 2 . The auxiliary boom 9 extends in the Y direction. On the cantilever 1 , a handle 4 is also connected to the same end as the hoisti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com