Rotary drum type screening joint machine

A screen section machine and rotary drum technology, which is applied in textile and papermaking, fiber raw material processing and other directions, can solve the problems affecting the pulping quality of the equipment, the pressure drop of the pulp pipe, and the increase of the motor current, etc. Energy loss, foam prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

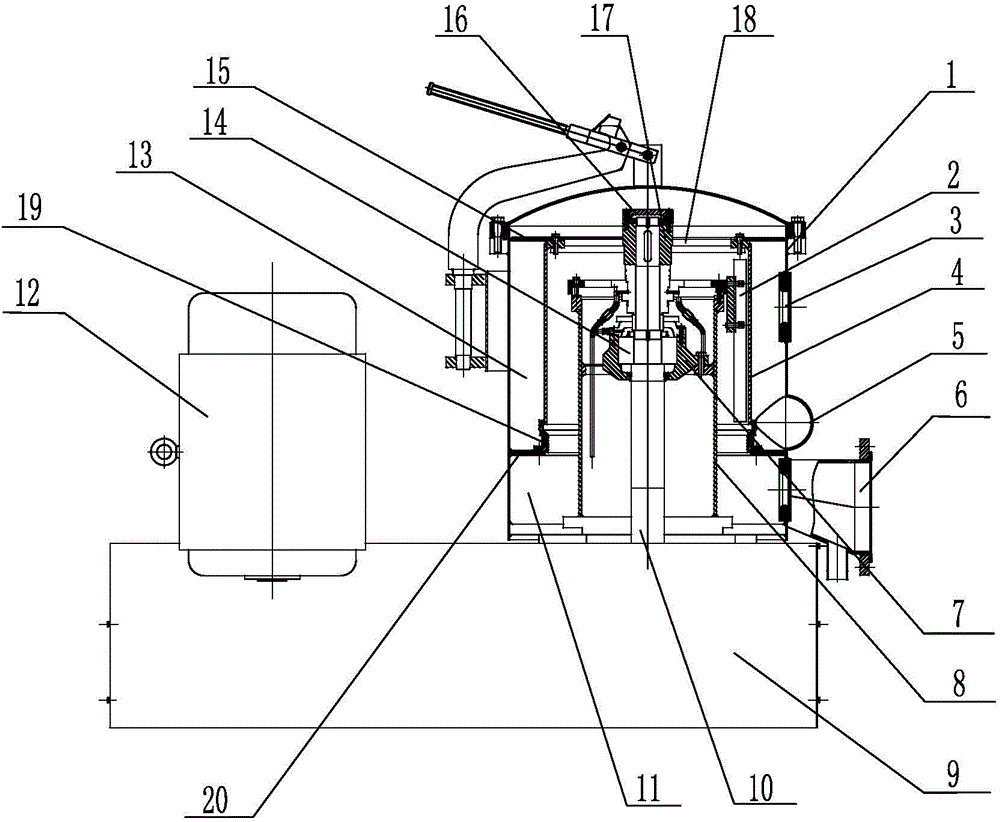

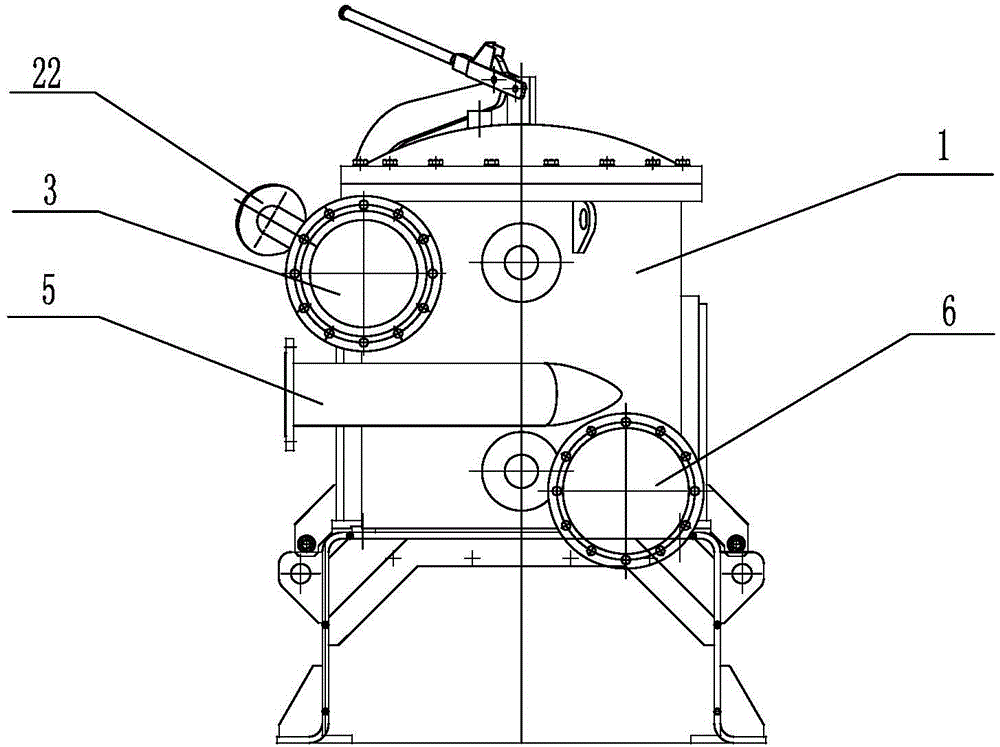

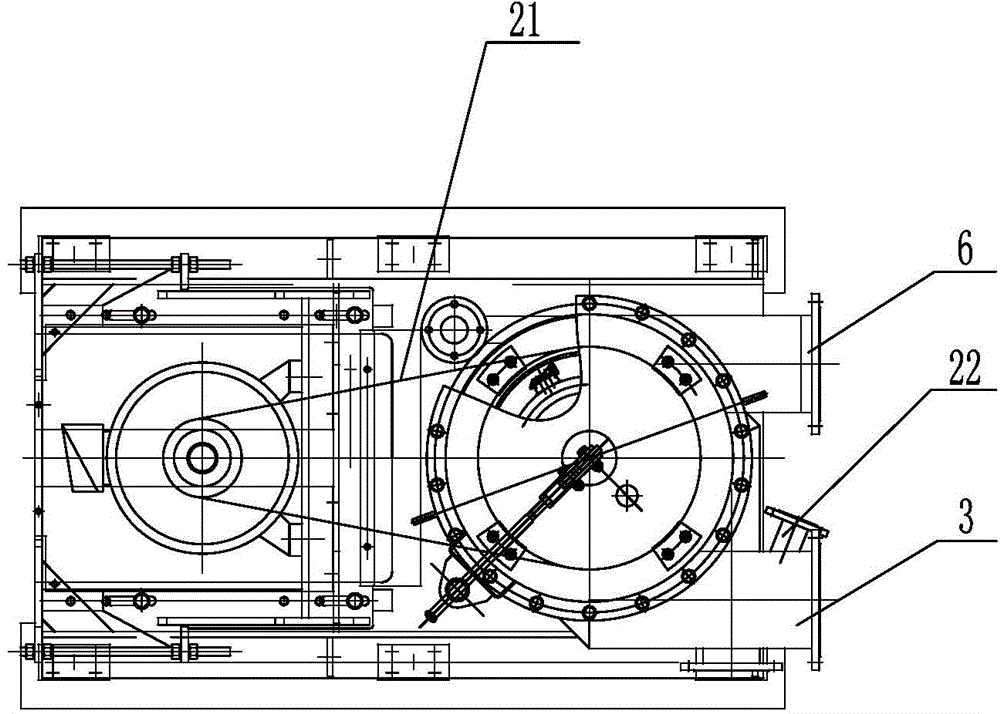

[0019] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

[0020] Such as Figure 1-Figure 3 As shown, the rotary drum screen section machine of the present invention includes a base 9, a motor 12 and a cylinder 1 are arranged on the base 9, an exhaust pipe is installed on the top of the cylinder 1, and a rotating shaft 10 is arranged in the cylinder 1 to rotate The shaft 10 is fixed in the rotating shaft sealing device 8 through the bearing 14 and the bearing bracket 7 and is fixed in the cylinder body 1 through the rotating shaft sealing device 8. The bottom of the rotating shaft 1 is connected to the rotating shaft of the motor 12 through a belt 21, and the top of the rotating shaft 10 is connected by a The piece 17 is connected with the rotating disk 18, the rotating disk 18 is connected with the top of the screen drum 4, the screen drum 4 is set on the outside of the rotating shaft sealing device 8, the inside of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com