Construction and implementation method of a tool-type anchorage end of a cantilevered external scaffold steel beam

A technology for external scaffolding and anchoring ends, which is applied to the accessories of scaffolding, scaffolding supported by house structures, building structures, etc., which can solve problems such as slow construction speed, low safety, and waste of steel, so as to improve construction speed and safety. , Fast installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

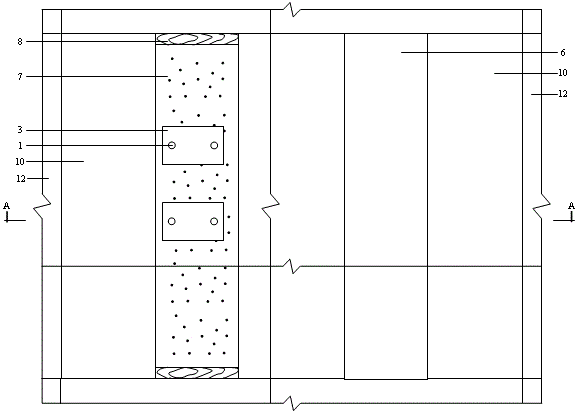

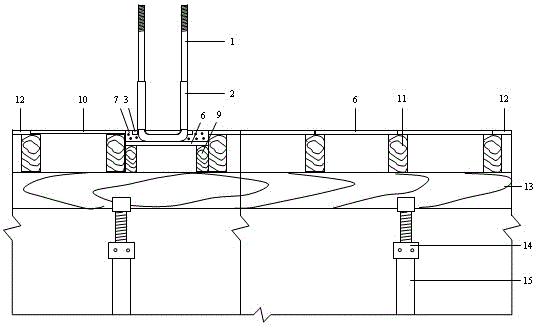

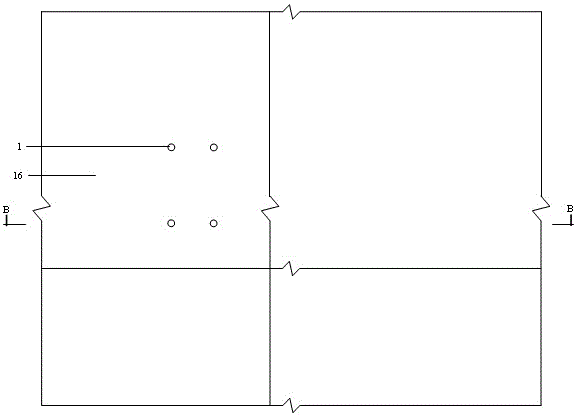

[0025] Depend on Figure 1-8 It can be seen that the structure of the tool-type anchorage end of a kind of cantilevered external scaffold steel beam includes a scaffold support with an adjustable support head 14 on the top of the φ48 steel pipe 15, a standard main keel 13 placed on the scaffold support, and a standard main keel. The standard sub-keel 11 placed above the keel along its vertical direction, the standard small formwork 10 for carrying the floor concrete 16 at the upper end of the standard sub-keel, the joint formwork 6 and the standard formwork 12, the PVC casing 2 passing through the concrete, and the steel backing plate 3 U-bolts 1 with PVC sleeves, steel beams 17 placed between the U-bolts, joint templates for bearing cement mortar 7 placed on non-standard sub-keels 9 under the steel beams, vertical Blocking wooden squares 8 respectively placed at both ends of the joint formwork, and steel pressure plates 4 pressed on the steel beams and fixed by nuts 5 .

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com