Fault arc online detecting method based on wavelet first-layer high-frequency component correlation

A high-frequency component and fault arc technology, applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., can solve the problems of short fault judgment time, long learning process, lack of versatility, etc., to achieve small calculation amount and convenient data Effects of computation and efficient transfer, increasing versatility and effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

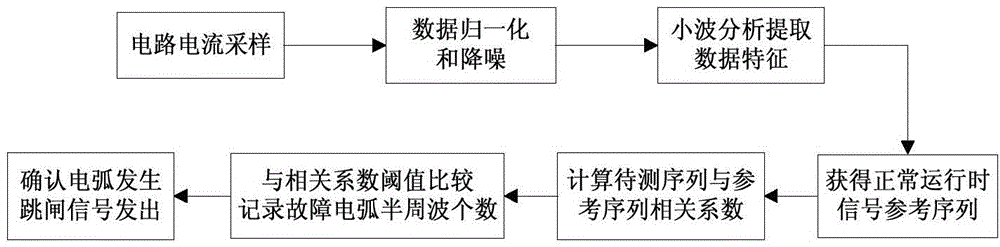

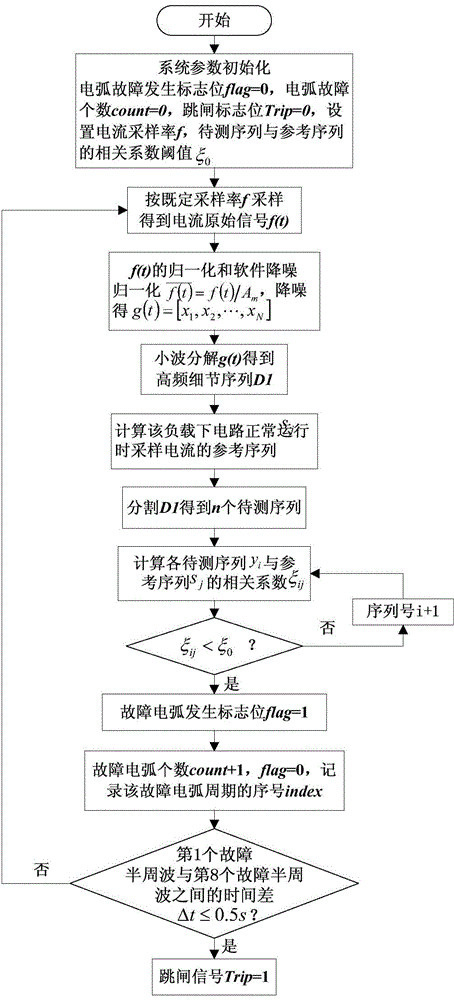

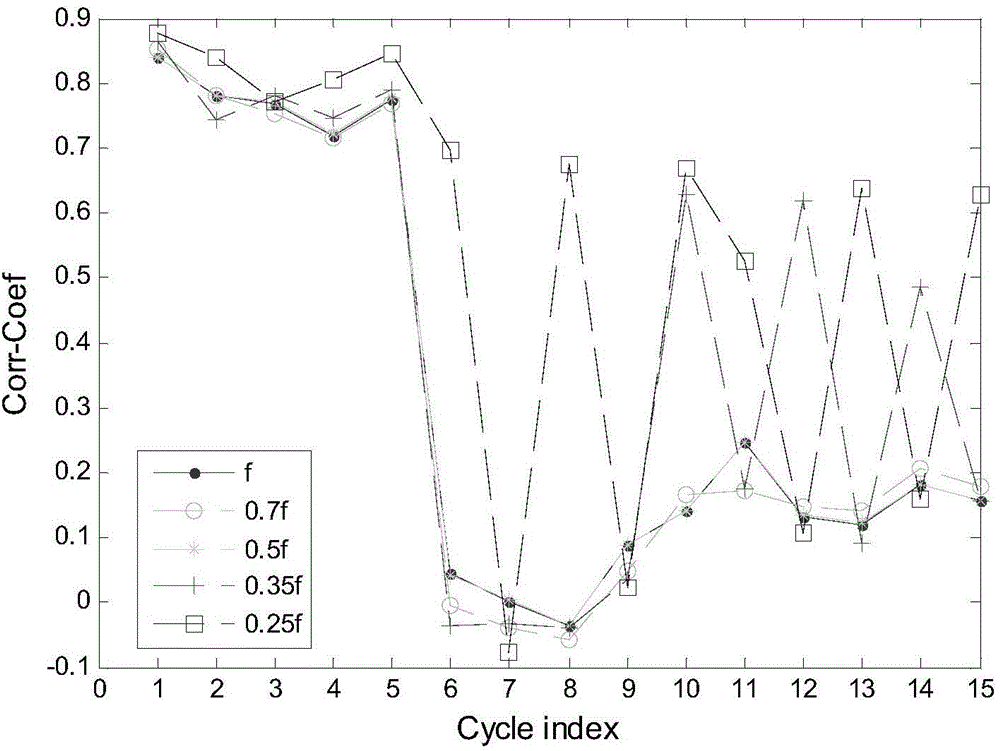

[0050] The used method structure diagram and program flow chart of the present embodiment are as follows figure 1 , figure 2 As shown, the load is a 1000W electric kettle resistive load, and the specific steps for fault arc identification are as follows:

[0051] 1) According to the sampling rate f=10 4 Hz collects the series current f(t) of the circuit where the load is located.

[0052] 2) The amplitude of the sampling current f(t) is A m , normalize f(t) to get Remove the external noise in the signal, and the normalized current sequence Carry out software noise reduction, get g(t)=[x 1 ,x 2 ,...,x N ].

[0053] 3) Select the db1 wavelet base ψ(t) in the Daubechies wavelet family to perform wavelet decomposition on g(t), Is a pulse function with a width of 1 and a height of 1, and calculates the high-frequency detail coefficient Obtain the high-frequency detail sequence D1 of g(t).

[0054] 4) Take the current of 5 cycles when the circuit operates norma...

Embodiment 2

[0065] Figure 5 It is the judging process of the fault arc when the detection method of the present invention is inductively loaded with a 500W electric drill. The specific steps of arc fault identification are the same as those in Embodiment 1. Figure 5 From top to bottom in the middle is the sampling current g(t) after the normalized noise reduction of the electric drill load, the high-frequency component sequence D1 of g(t), and the sequence to be measured y i with reference sequence s j The correlation coefficient ξ ij , the trip signal flag of the circuit where the load is located is Trip. Depend on Figure 5 It can be seen that the algorithm of the present invention can realize the accurate identification and judgment of the fault arc in the electric drill with inductive load.

Embodiment 3

[0067] Figure 6 It is the judging process of the fault arc when the detection method of the present invention is used for a capacitive load of a 50W capacitive start-up fan. The specific steps of arc fault identification are the same as those in Embodiment 1. Figure 6 From top to bottom in the figure are the sampling current g(t) after the normalized noise reduction of the capacitive start-up fan load, the high-frequency component sequence D1 of g(t), and the sequence to be measured y i with reference sequence s j The correlation coefficient ξ ij , the trip signal flag of the circuit where the load is located is Trip. Depend on Figure 6 It can be seen that the algorithm of the present invention can realize the accurate identification and judgment of the fault arc when the capacitive load capacitor starts the fan.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap