Pantograph-catenary electric arc detection method and system based on train power supply system

A technology of a power supply system and a detection method, which is applied in the field of trains and can solve problems such as large energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

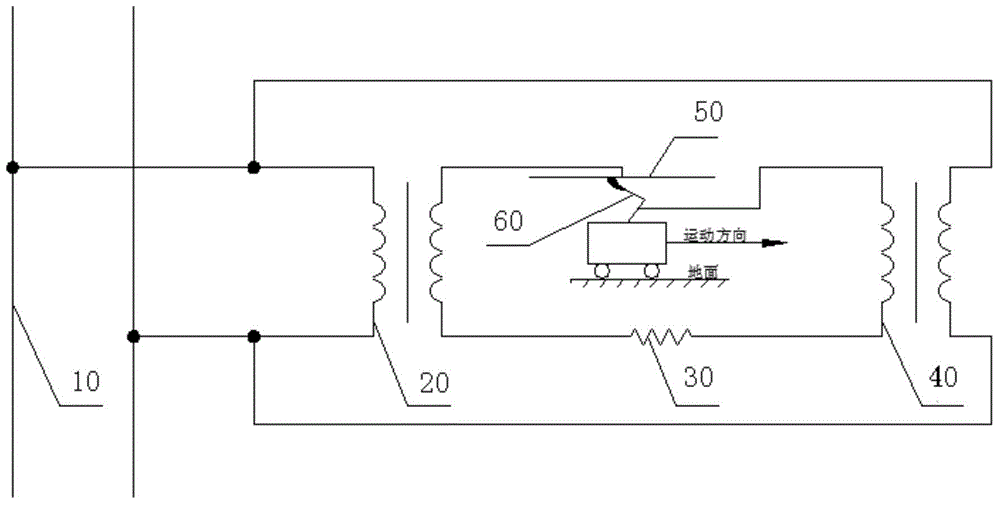

[0017] An embodiment of the present invention provides a pantograph-catenary arc detection method based on a train power supply system. Such as figure 1 As shown, the power supply system may include: a grid 10 , a step-up transformer 20 , a current limiting resistor 30 , a step-down transformer 40 , catenary conductors 50 , and a discharge circuit formed by a pantograph 60 .

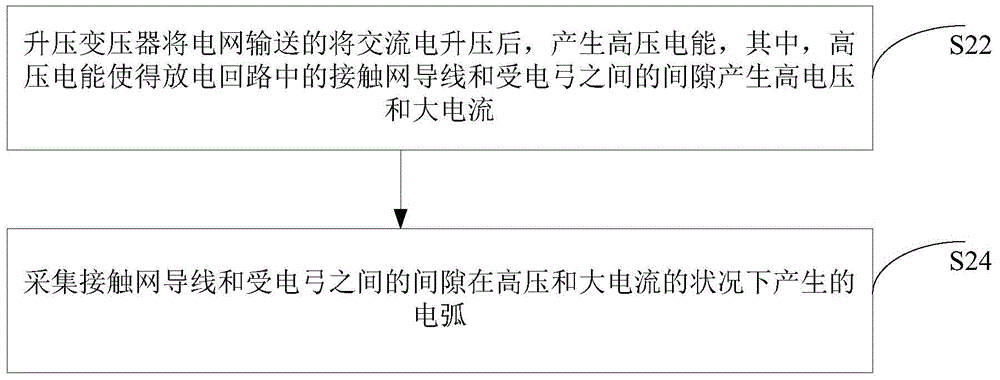

[0018] Such as figure 2 As shown, the method may include the following steps:

[0019] In step S22, the step-up transformer boosts the alternating current delivered by the grid to generate high-voltage electric energy, wherein the high-voltage electric energy causes the gap between the catenary wire and the pantograph in the discharge circuit to generate high voltage and large current.

[0020] Specifically, in this solution, the above-mentioned step-up transformer can transmit the high-voltage electric energy after the above-mentioned boost to the discharge circuit, that is, the step-up transformer 2...

Embodiment 2

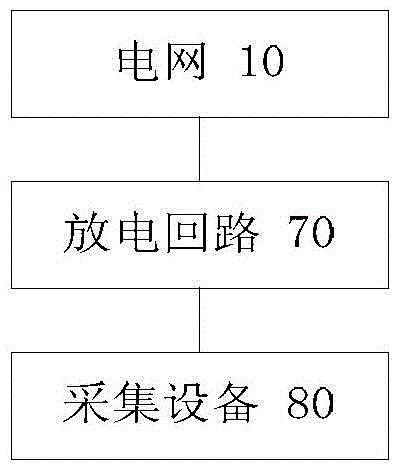

[0045] An embodiment of the present invention provides a pantograph-catenary arc detection system based on a train power supply system. Such as image 3 As shown, the system can include:

[0046] The grid 10 is used to transmit electric energy.

[0047] The discharge circuit 70 includes: a step-up transformer 20, a current-limiting resistor 30, a catenary wire 50, and a pantograph 60, wherein the step-up transformer 20 is used to boost the alternating current delivered by the power grid to generate high-voltage electric energy, wherein, The high-voltage electric energy makes the gap between the catenary conductor 50 and the pantograph 60 in the discharge circuit generate high voltage and large current.

[0048] The collection device 80 is used to collect the arc generated by the gap between the catenary wire and the pantograph under the condition of high voltage and high current.

[0049] Specifically, the above-mentioned step-up transformer can deliver the above-mentioned ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com