Hydrometallurgical gold cyanide leaching optimization method

A hydrometallurgy and process optimization technology, applied in the direction of instruments, adaptive control, control/regulation systems, etc., can solve the problems of blindly excessive addition, insufficient raw material addition, waste, etc., and achieve the effect of avoiding raw material waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

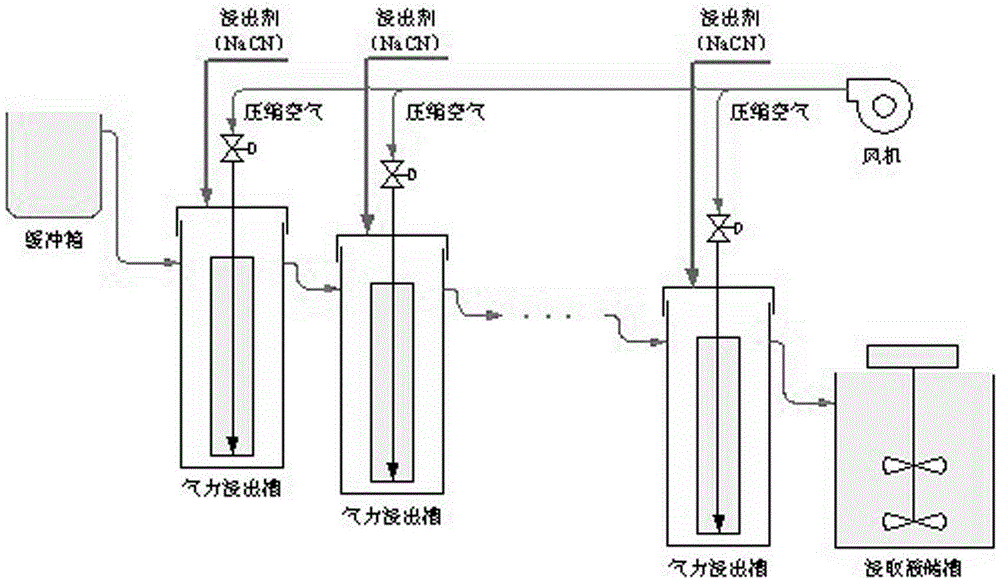

[0181] Embodiment 1: online optimization of gold cyanide leaching process

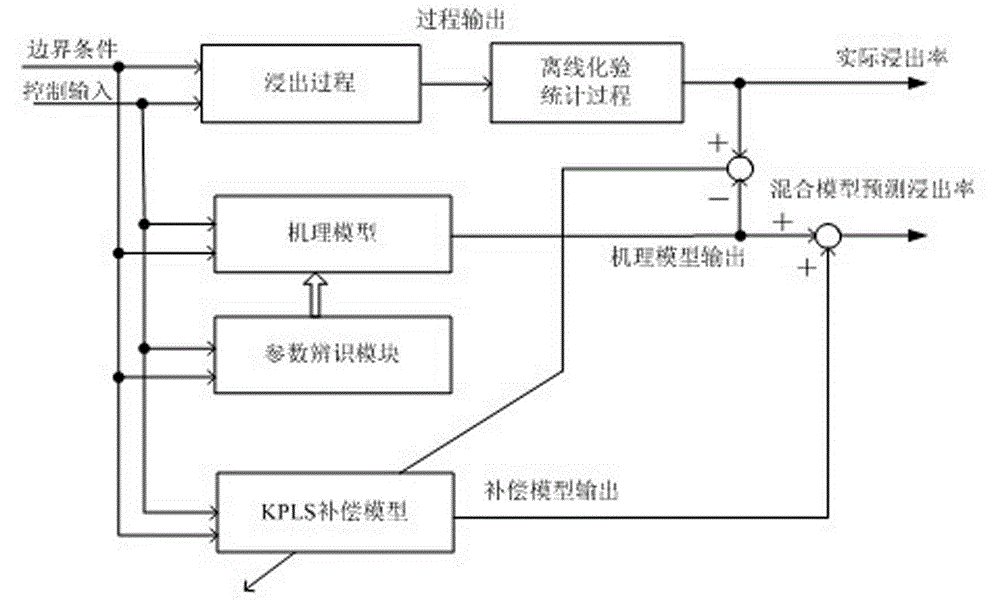

[0182] The first step, selection of auxiliary variables: the selection of auxiliary variables is the first step in establishing optimization. This step determines the input information matrix of the optimization model, which is crucial to the success of the optimization operation. The selection of auxiliary variables includes the selection of variable type, the selection of variable number and the selection of detection point location.

[0183] The auxiliary variables selected in the present invention include: ore flow, sodium cyanide flow, dissolved oxygen concentration, pulp concentration, particle size, initial gold grade, and initial sodium cyanide concentration.

[0184] The second step, data collection: data collection was carried out at the site of the leaching process.

[0185] Since in practical problems, the measurement units of each variable are inconsistent, without certain processing, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com