An equipment wire connector

A technology of wire joints and equipment, which is applied in the direction of connection, contact parts, two-part connection devices, etc., can solve the problems of difficult measurement process, poor contact, and affecting line stability, etc., and achieve good contact and stable connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

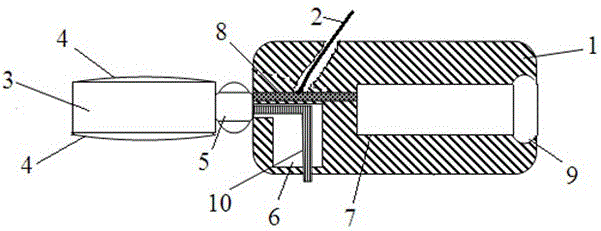

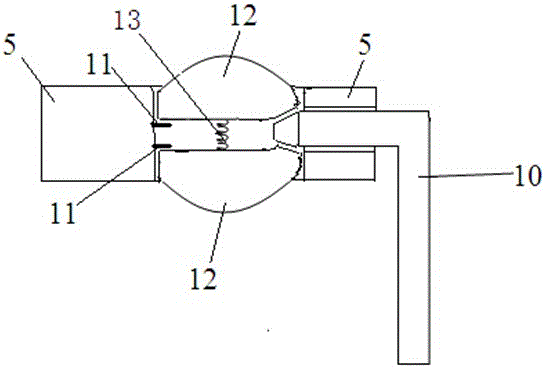

[0013] refer to figure 1 and figure 2 , the device wire connector of the present invention includes a metal columnar plug 3, a metal columnar connector 5 and an insulating column 1. The surface of the metal columnar plug 3 is evenly distributed with a number of strip copper sheets 4. The length is 2-4mm, and the two ends of the copper sheet are respectively fixed with the two ends of the metal cylindrical plug. The insulating cylinder 1 has a copper core 8, and one end of the insulating cylinder 1 has a bending channel 6, and the bending channel 6 is provided with a dial One end of the toggle switch 10 located on the end face of the insulating cylinder is wedge-shaped, the other end of the insulating cylinder 1 has a metal socket 7 into which the metal cylindrical plug can be inserted, and one end of the copper core 8 is connected to the metal cylindrical connector 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com