High-frequency connector

A technology of high-frequency connectors and grounding strips, which is applied in the direction of connection, parts of connecting devices, electrical components, etc., and can solve problems such as deformation of shrapnel, affecting the contact stability of grounding strips, and strong signal interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

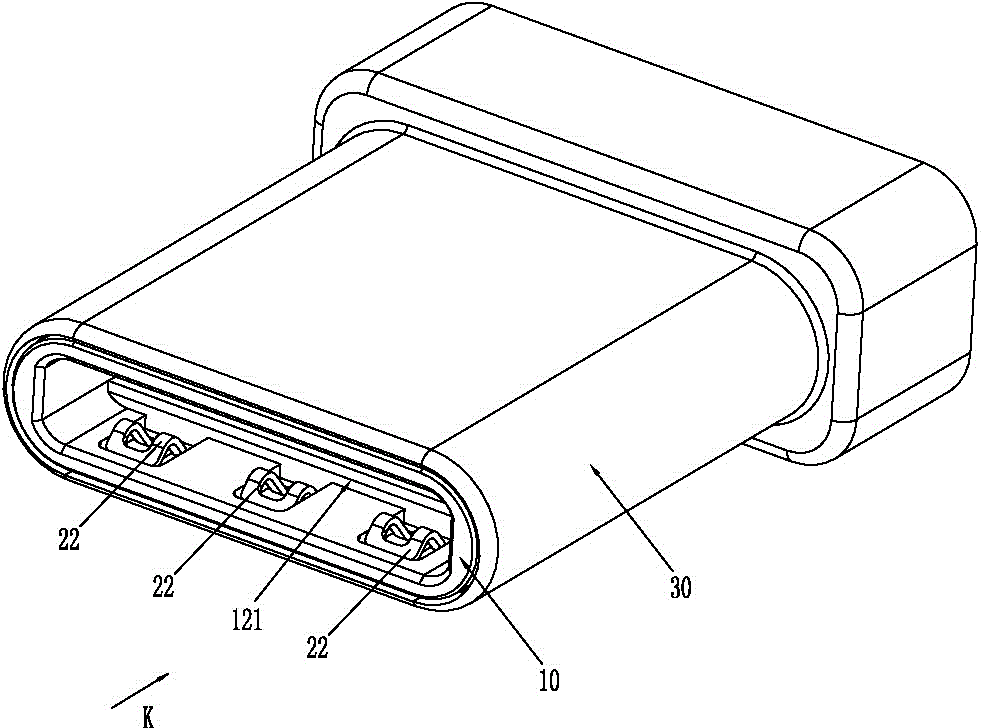

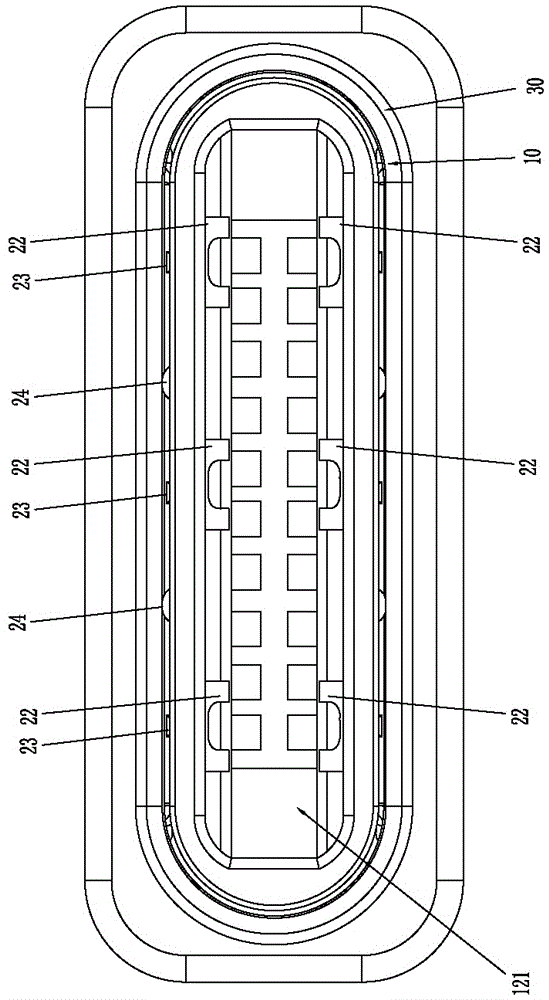

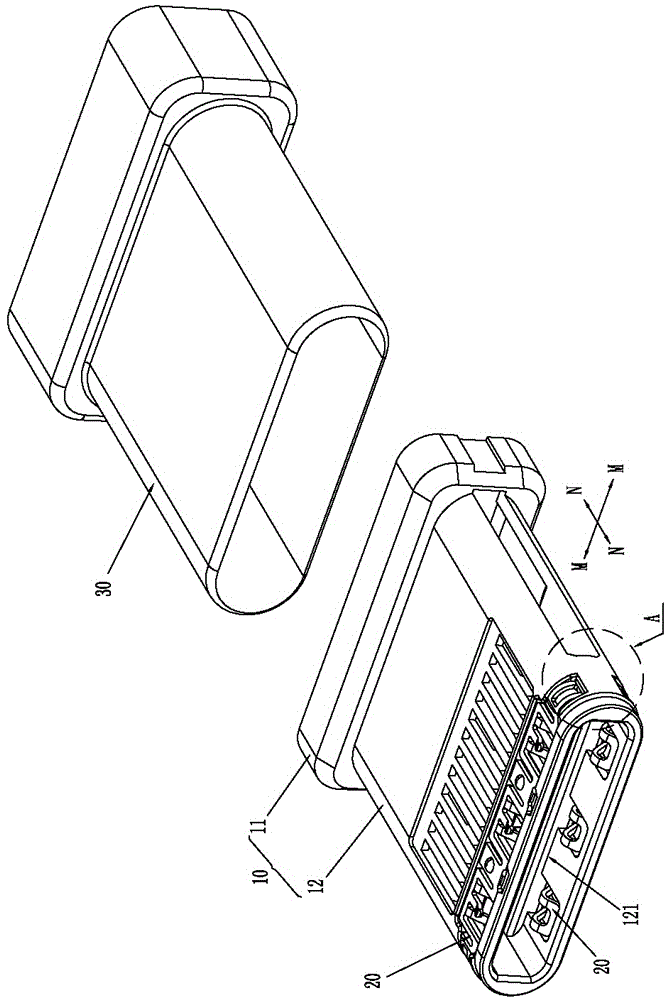

[0036] Please refer to Figure 1 to Figure 7 As shown, it shows the specific structure of the embodiment of the present invention. Here, a high-frequency plug connector is taken as an example for illustration; it includes an insulating body 10, contact terminals (not shown in the figure), grounding sheet 20 and shielding shell 30, the insulating body 10 includes a base 11 and a tongue 12 integrally connected to the front side of the base 11, the front end of the tongue 12 is concavely provided with a slot 121, and the aforementioned contact terminals are exposed on the Inside slot 121.

[0037] The grounding piece 20 is set against the front end of the slot 121, and the grounding piece 20 is located on the front side of the contact terminal, and only the upper side surface or only the lower side surface or the upper and lower side surfaces of the tongue plate 12 are recessed towards the slot 121. There is an installation concave cavity 122 for setting the grounding sheet 20, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com