Low-power consumption three-level operational amplifier for driving large-load capacitor

An operational amplifier and low power consumption technology, which is applied in the field of multi-stage operational amplifiers, can solve the problems of increased circuit manufacturing costs and increased chip area, and achieve the effect of good slew rate and large gain-bandwidth product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, but the implementation scope of the present invention is not limited thereto.

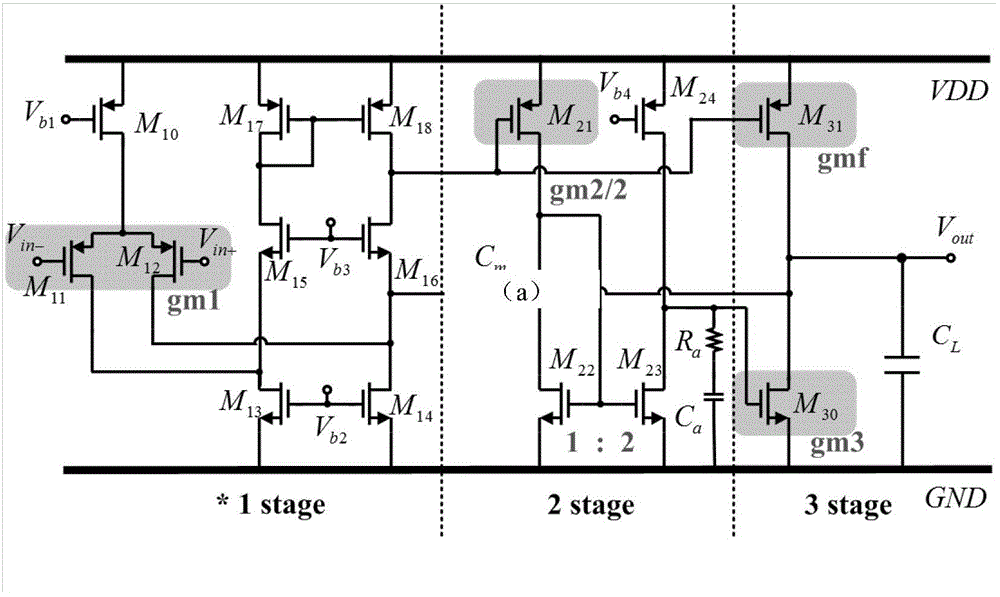

[0013] This multi-stage operational amplifier consists of 15 MOS transistors (where PMOS: M 10 , M 11 , M 12 , M 17 , M 18 , M 21 , M 24 and M 31 ;NMOS:M 13 , M 14 , M 15 , M 16 , M 22 , M 23 and M 30 ), two capacitors, that is, the first compensation capacitor Cm and the second compensation capacitor Ca, and one resistor Ra. Connection method: M 10 , M 17 , M 18 , M 21 , M 24 and M 31 The source is connected to the power supply V DD ; except M 11 and M 12 outside of the substrate terminated source, M 10 , M 17 , M 18 , M 21 , M 24 , and M 31 The substrate terminated power supply V DD . m 13 , M 14 , M 22 , M 23 and M 30 The source of the common ground GND; M 13 , M 14 , M 15 , M 16 , M 22 , M 23 and M 30 The substrate side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com