Solvent extraction settler arrangement

A settling tank and extraction technology, applied in the field of solvent extraction settling tank equipment, to achieve the effects of less dirt accumulation, lower solution cost, and lower oxidation degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

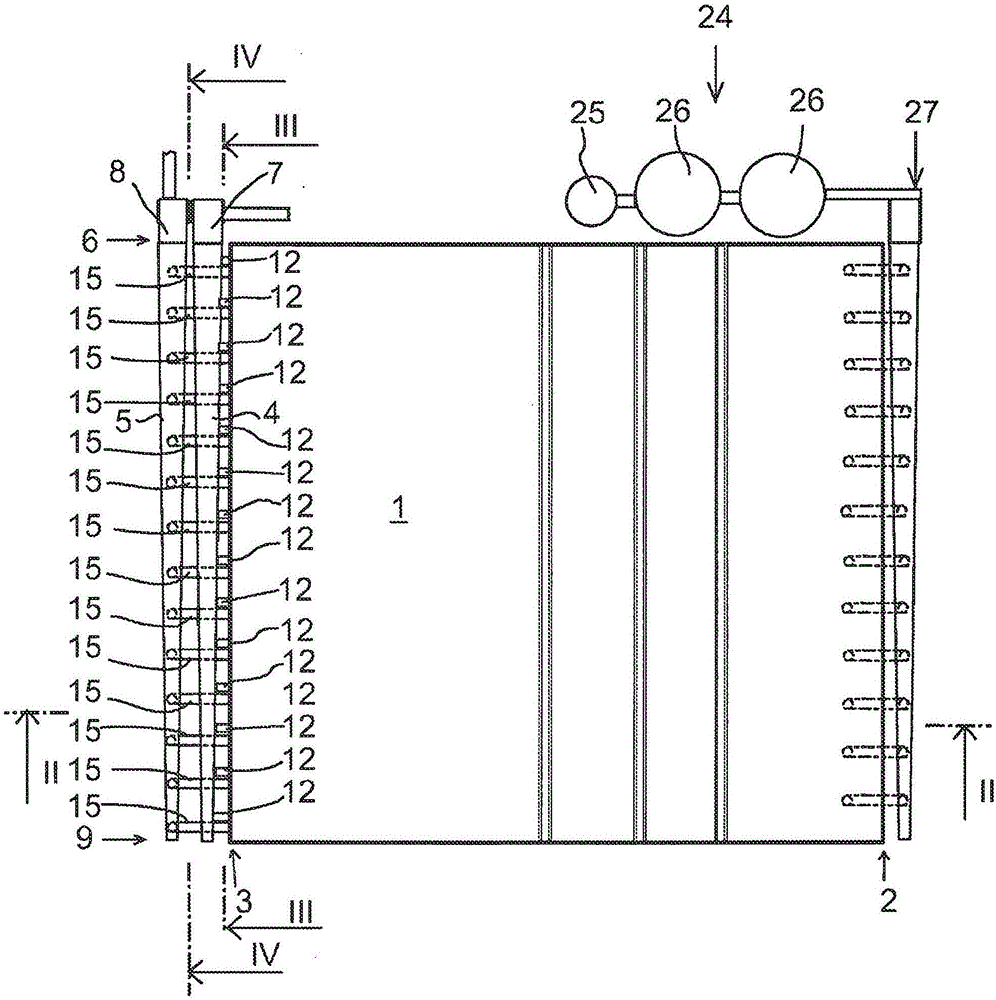

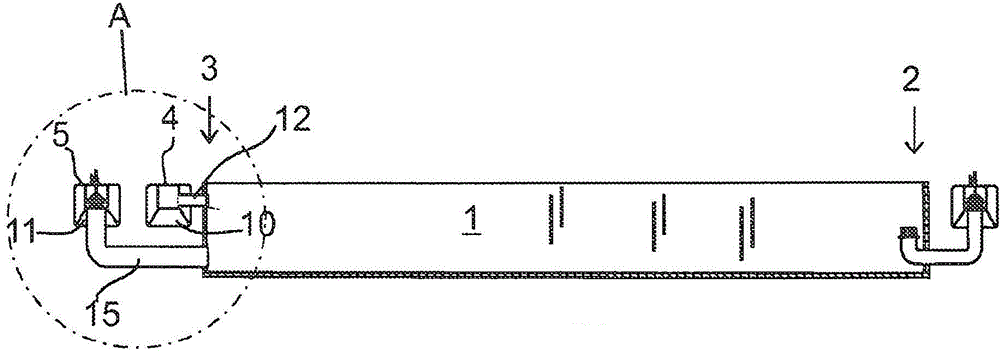

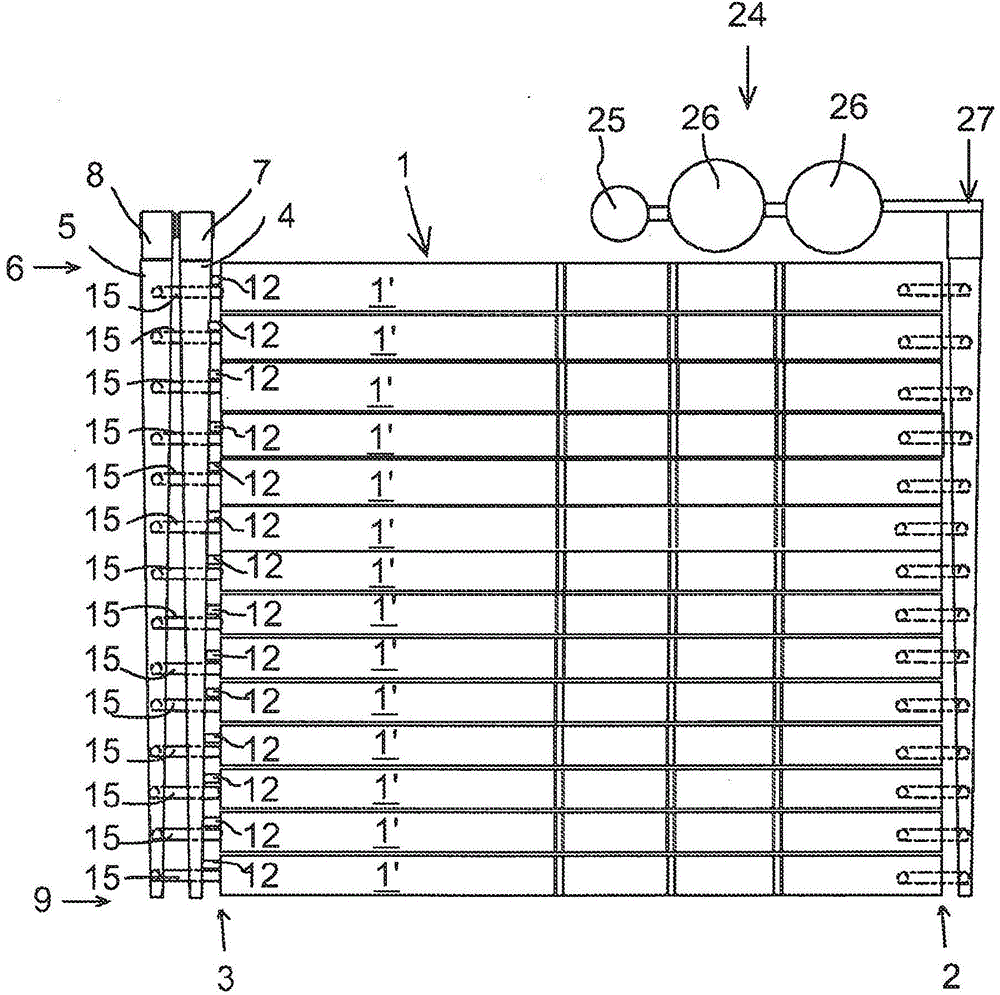

[0030] figure 1 with 3 A solvent extraction settling tank apparatus suitable for a hydrometallurgical liquid-liquid extraction process is shown.

[0031] The settling tank apparatus comprises a mixing unit 24 for preparing dispersions from mutually immiscible solutions. In this case, the mixing unit 24 comprises a pumping unit 25 and two mixers 26 . The settling tank 1 is arranged to separate the solution phase from the dispersion supplied at the feed end 2 while the dispersion flows towards the discharge end 3 . A feed device 27 is arranged at the feed end 2 for feeding the dispersion prepared by the mixing unit 24 to the settling tank 1 .

[0032] Elongated discharge channels 4 and 5 are arranged at the discharge end 3 to collect and discharge the separated solution. Each discharge chute 4 , 5 comprises a first end 6 , an outlet 7 , 8 arranged at the first end 6 , and a closed second end 9 .

[0033] as in figure 1 , 2 , 4 and 5, the two discharge grooves 4, 5 have th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com