Reactor for preparing iron oxide red

An iron oxide red, reactor technology, applied in iron oxide, iron oxide/iron hydroxide, chemical/physical/physical-chemical stationary reactors, etc., can solve the problem of uneven distribution of product particles, dead corners of reaction, and decreased reaction efficiency And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

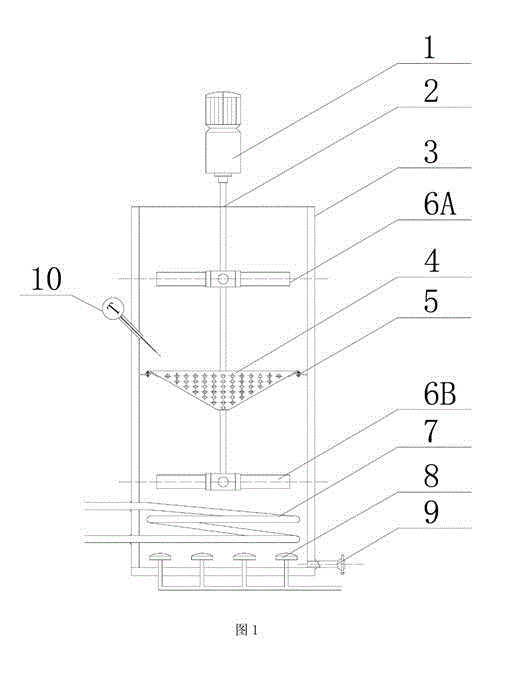

[0012] Below in conjunction with accompanying drawing, the present invention will be further described: the schematic diagram of the reactor mechanism of preparing iron oxide red provided by the present invention is as follows figure 1 Shown: by the reaction tank, frequency conversion motor. Main shaft, conical distribution plate, fixing device, first stirring impeller, second stirring impeller, heating coil, aeration pan, sewage outlet and thermometer; among them, a frequency conversion motor is installed in the center of the top of the reaction tank, and the frequency conversion motor is connected to the main shaft, the main shaft The first stirring paddle and the second stirring paddle are respectively installed up and down. The conical air distribution plate is fixed on the inner wall of the reaction tank through a fixing device and its height is between the first stirring paddle and the second stirring paddle. The bottom of the reaction tank is equipped with Aeration pan,...

Embodiment 2

[0014] The device in this embodiment is the same as in Embodiment 1, wherein the conical distribution plate is a porous plastic plate with a circular through hole on the surface, and the empty area is 1 cm 2 , the number of empty spaces per square meter is 5000.

[0015] Add the reaction raw material ferrous sulfate solution into the reaction tank, add sodium hydroxide solution to adjust the pH value to 8, feed steam to the heating coil to 75 degrees, feed air from the aeration plate at the bottom of the reaction tank, and start the frequency conversion motor to drive the stirring The paddle rotates and stirs, and the air entering from the aeration plate at the bottom of the reaction tank enters the upper part of the reaction tank through the conical air distribution plate, and the reaction materials in the reaction tank are fully mixed. After 2.5 hours of reaction, the color paste in the reaction tank meets the requirements, and the reaction is stopped. Compared with conventi...

Embodiment 3

[0017] The structure of the reactor in this example is the same as in Example 1, wherein the conical air distribution plate is a porous stainless steel plate with square through holes on the surface; the hole diameter is 10 cm, and the number of holes per square meter is 80.

[0018] Add the reaction raw material ferrous sulfate solution into the reaction tank, add sodium hydroxide solution to adjust the pH value to 9, feed steam to the heating coil to 90 degrees, feed air from the aeration tray at the bottom of the reaction tank, and start the frequency conversion motor to drive the stirring The paddle rotates and stirs, and the air entering from the aeration plate at the bottom of the reaction tank enters the upper part of the reaction tank through the conical air distribution plate, and the reaction materials in the reaction tank are fully mixed. After 2 hours of reaction, the color paste in the reaction tank meets the requirements, and the reaction is stopped. Compared with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com