Stainless steel sheet wire-drawing device for controlling wire-drawing stroke

A stainless steel and plate technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing, etc., can solve problems such as visual fatigue, large errors, safety accidents, etc., and achieve the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

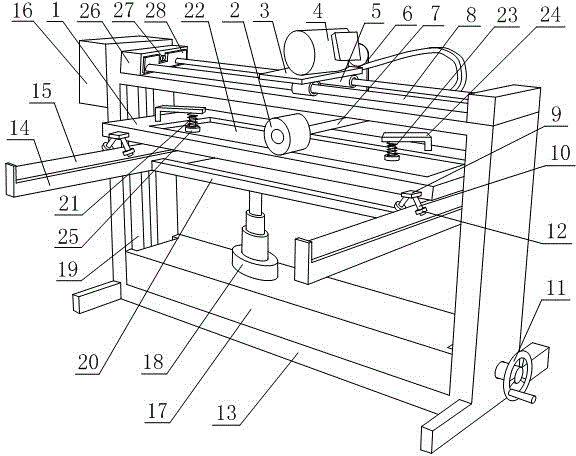

[0012] Such as figure 1As shown, the stainless steel plate wire drawing device for controlling the wire drawing stroke includes an internal hollow support frame 13, a support platform 1 is arranged in the cavity of the support frame 13, and a limit frame is arranged below the support platform 1, and the support platform 1 can move along the Sliding horizontally against the limit frame, the top surface of the support platform 1 is concaved to form a mounting groove 22, and the center of the mounting groove 22 is set on the center line of the support platform 1, and the top surface of the support platform 1 is provided with several support arms. 24. The bottom ends of the support arms 24 are all fixed to the top surface of the support platform 1. The support arms 24 are in an L-shaped structure. The support arms 24 are all provided with compression springs 23. Fixed, the compression springs 23 are all arranged directly above the installation groove 22, and the compression spring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com