Method for manufacturing and controlling camber of crane main girder

A crane and camber technology, applied in manufacturing tools, welding equipment, metal processing, etc., can solve problems such as complex transfer, affecting material performance, and large demand for casting platforms, so as to avoid secondary damage, reasonable welding sequence, and low cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

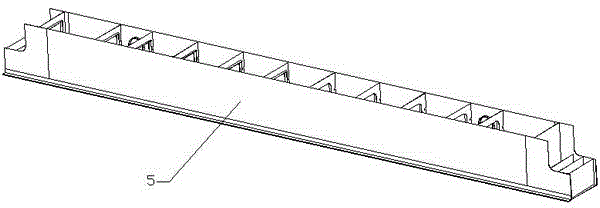

[0019] The following is a detailed description based on the structural diagram of a method for producing and controlling the crown of the main girder of a crane shown in the accompanying drawings: a method for producing and controlling the crown of the main beam of a crane, the specific steps are:

[0020] a) Tailor-weld angle steel or T-shaped bar with the remaining material or material head cut from the plate, and prefabricate all of them into a uniform length as the tire frame profile;

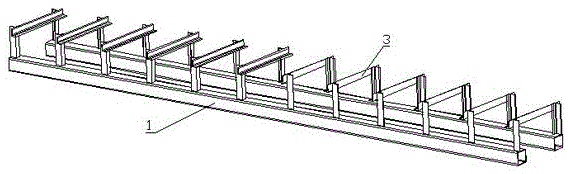

[0021] b) Weld the prefabricated tire frame profile to the embedded part 1 on the ground of the workshop, and calculate the reserved camber of the main girder of the crane;

[0022] c) Use the theodolite to transfer all the reserved camber value to each tire frame profile, and weld the transverse profile 3 at this height;

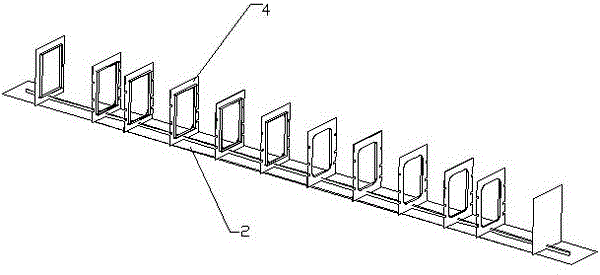

[0023] d) Lay the main beam bottom plate 2 to match the reserved camber, and fix it with the tire frame;

[0024] e) Assemble the transverse diaphragm 4 in the beam, we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com