Multi-hole distributor pipe welding machine

A technology for separating oil pipes and welding machines, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve problems such as affecting production efficiency, wasting time, increasing work, etc., saving inspection time and manpower, reducing production costs, and improving The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described below in conjunction with accompanying drawing.

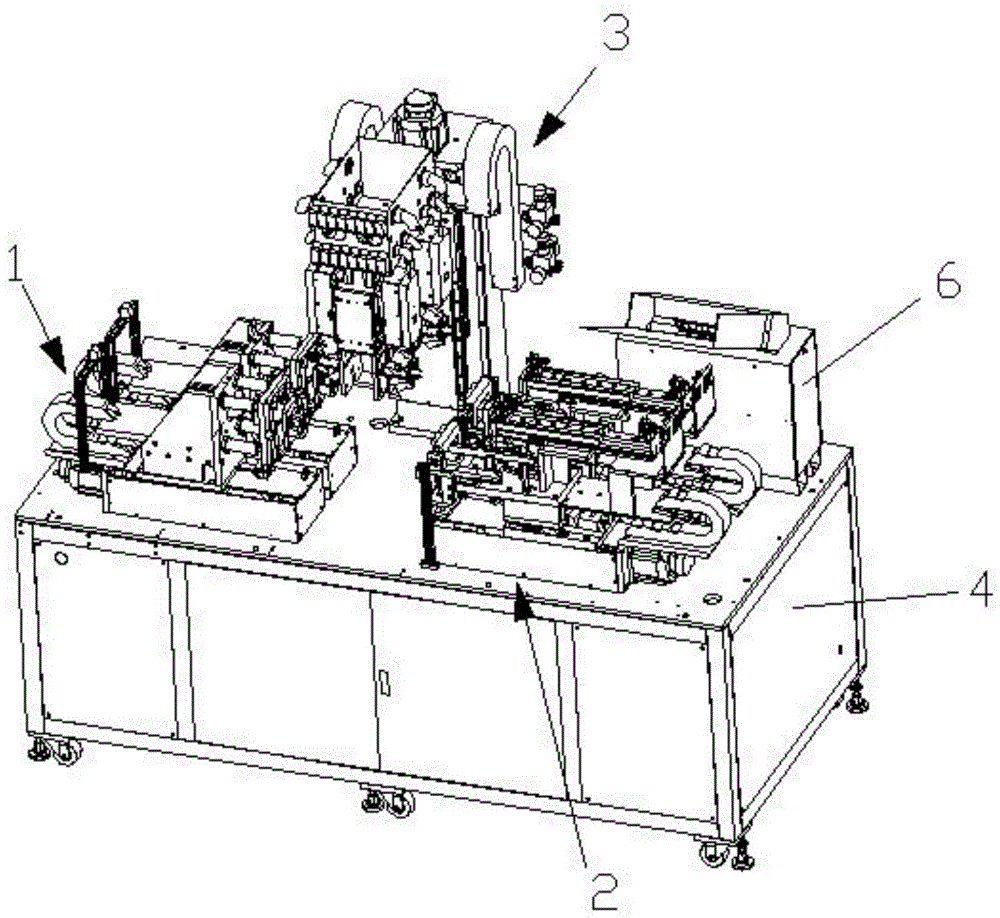

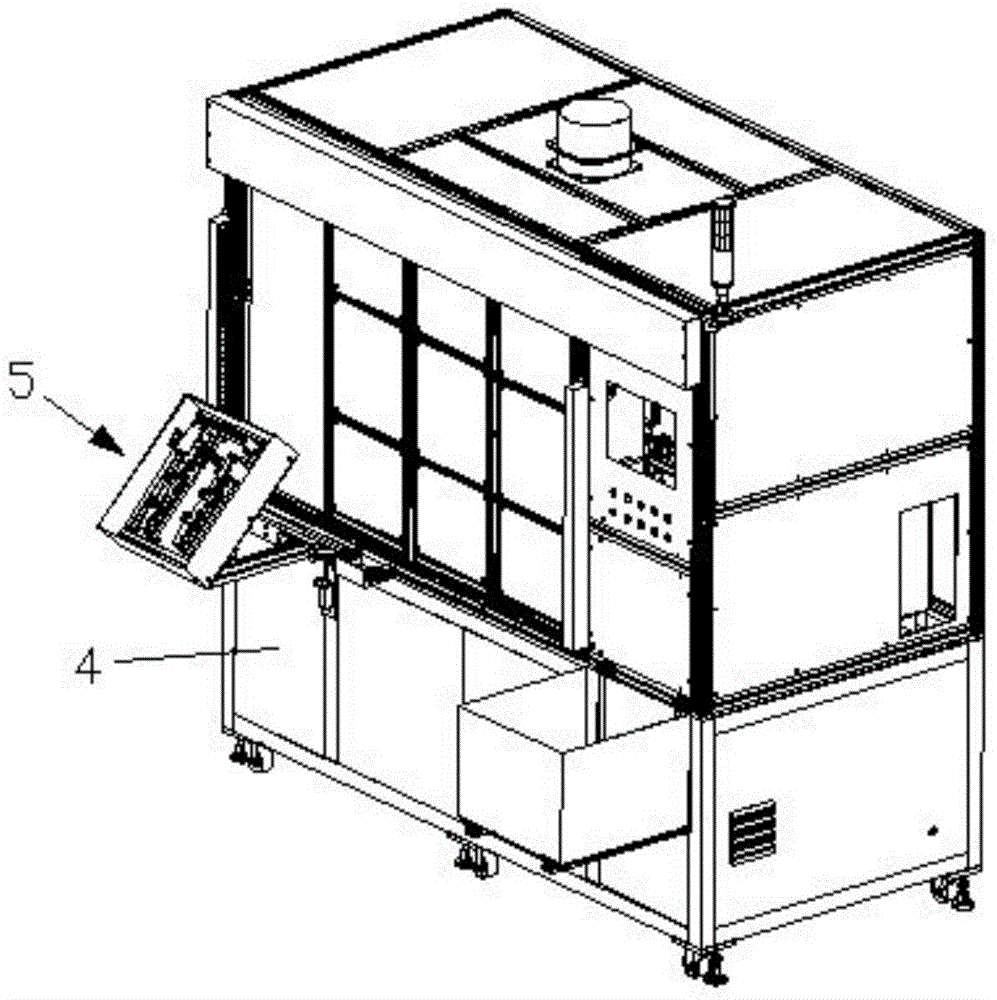

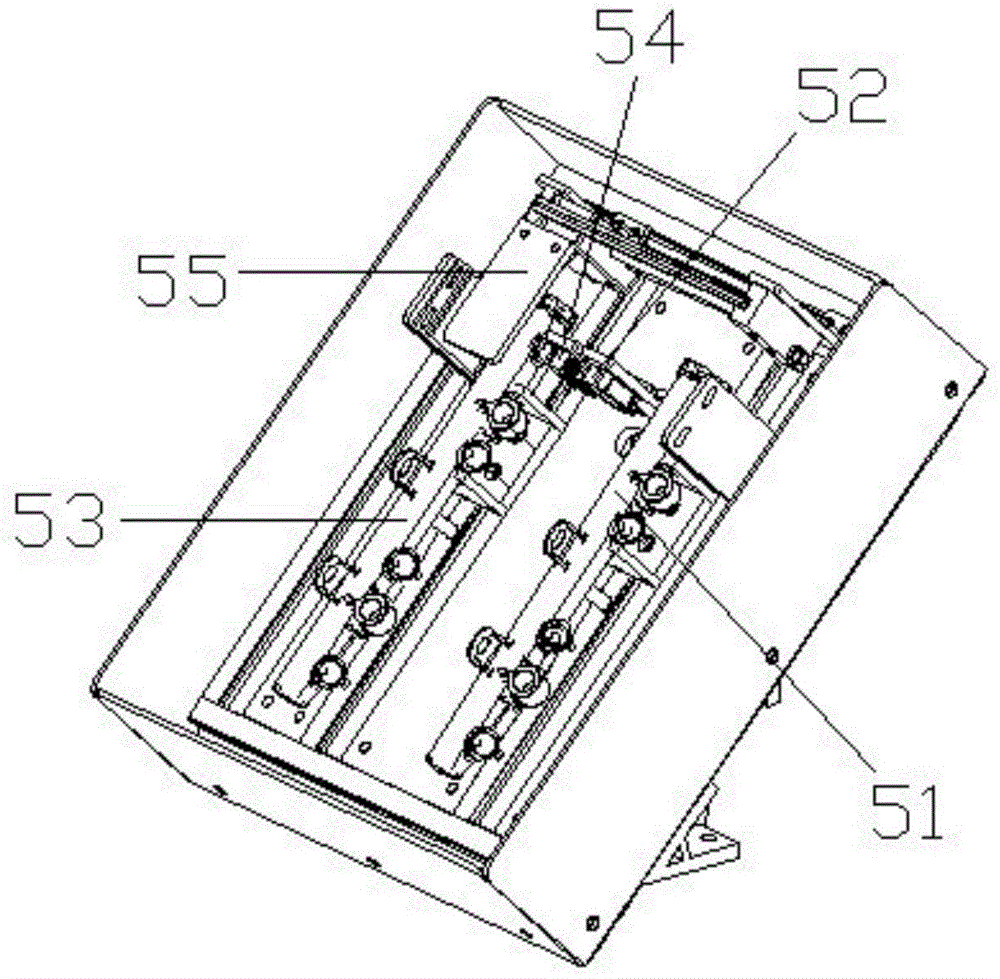

[0026] attached Figure 1-3 The present invention includes an end cap fixing device 1, a pipe body fixing device 2, an infrared heating device 3 and a machine platform 4, and the infrared heating device 3 is arranged on the machine platform 4; two sets of end cap fixing devices 1 are arranged side by side On one side of the infrared heating device 3, there are a first hole end cover fixing device and a second hole end cover fixing device; the other side of the infrared heating device 3 is correspondingly provided with a first hole tube body fixing device and a second hole tube body fixing device, the end cover The fixing device 1 and the tube body fixing device 2 can be moved relative to each other to achieve docking; firstly, the end cap and the tube body are respectively fixed on the end cap fixing device 1 and the tube body fixing device 2, and then the end cap fixing device 1 and th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap