Inclined hole processing device with adjustable angles

A technology for processing devices and oblique holes, which is applied to positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of inaccurate positioning angles, time-consuming and labor-intensive problems, and achieve the effects of rapid adjustment, simple operation, and saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

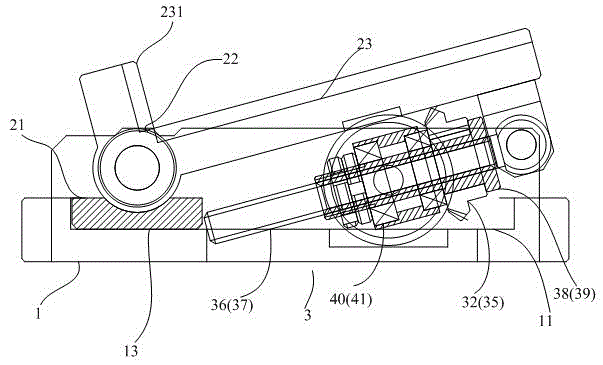

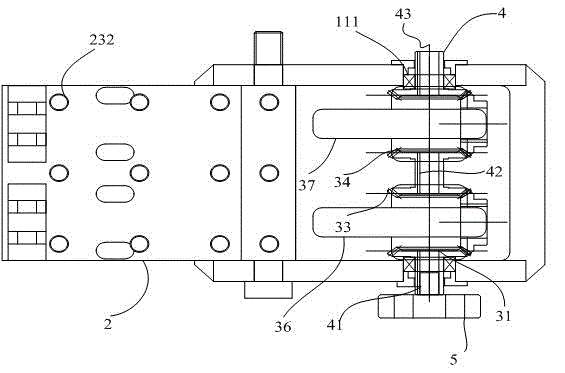

[0019] see Figure 1-Figure 2 , an embodiment of an angle-adjustable inclined hole processing device of the present invention, comprising a base 1, a rotary table 2, a transmission device 3, a rotating shaft 4 and a handle 5, and the rotary table 2 is hinged to one end of the base 1; The base 1 is provided with a groove 11, the groove 11 is provided with a support plate 13, the rotating shaft 4 includes a rotating shaft 41 and a rotating shaft 2 42, and the rotating shaft 41 is arranged on the side wall of the groove 11 Above, the first rotating shaft 41 is fixedly connected to the handle 5, and the second rotating shaft 42 is arranged on the support plate 13; the transmission device 3 includes a driving gear 31, a driven gear 1 32, and a driven gear 2 33 , driven gear three 34, driven gear four 35, screw mandrel one 36, screw mandrel two 37, screw nut one 38 and scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com