Solar cell module edge trimming machine edge trimming device

A technology of solar cells and trimming devices, which is applied to electrical components, circuits, semiconductor devices, etc., can solve the problems that trimming devices cannot adapt to mechanized production, and achieve the effect of easy cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

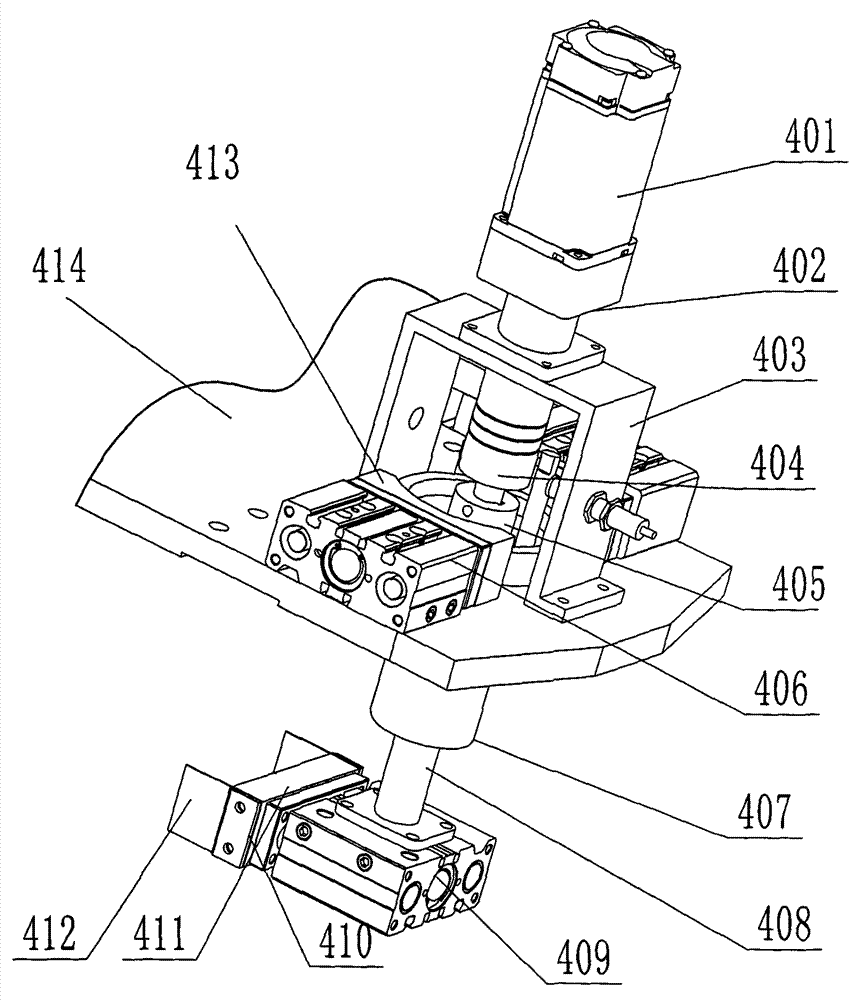

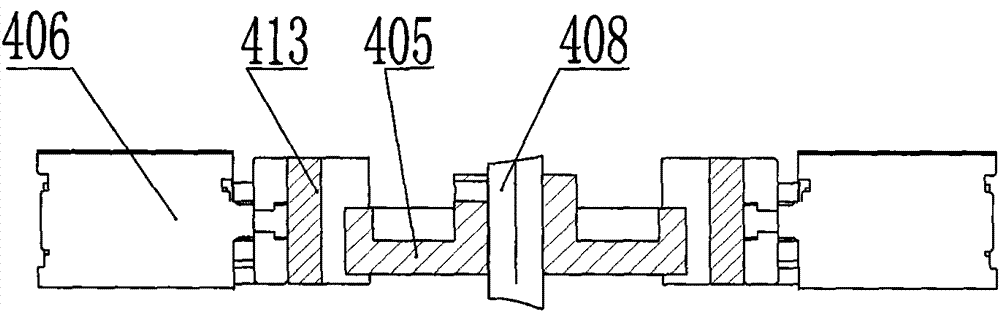

[0021] Such as Figure 1-2 As shown, the edge trimming device of this solar cell module edge trimming machine is composed of an edge trimming knife 412, a cutting angle adjustment motor, and a shaft holding device. The output end of the cutting angle adjustment motor is fixed to one end of the connecting shaft 408 through a coupling 404. Connection, the other end of the connecting shaft 408 is connected with the edge trimming knife 412. The shaft clamping device is composed of two clamps 413 and a clamping drive 406 which can be contacted with the clamping disc 405 and the clamping drive 406. The clamping disc 405 is coaxially fixed outside the connecting shaft 408, and each clamping clamp consists of a Tightly drive 406 to drive, and two clamps are relatively arranged, and the preferred cylinder is used as the drive 406 for clamping, and the clamp 413 is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com