Swing Marble Multi-wire Cutting Machine

A multi-wire cutting machine and marble technology, applied in stone processing equipment, working accessories, manufacturing tools, etc., can solve the problems of long contact line, high cutting resistance, low cutting efficiency, etc., and achieve small slits and low material waste rate , high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

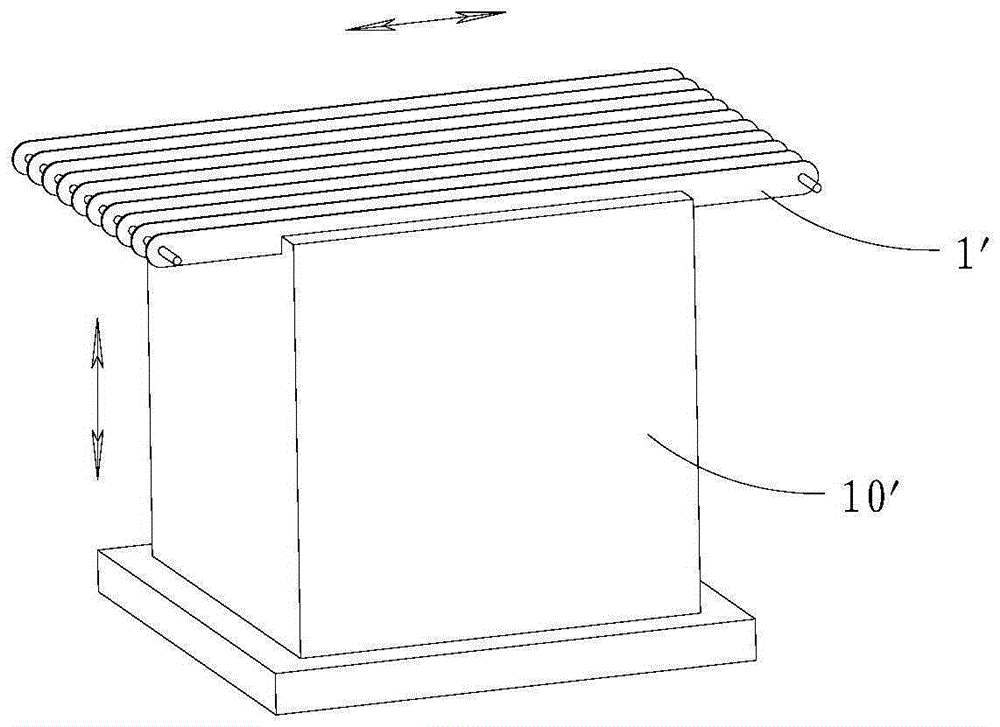

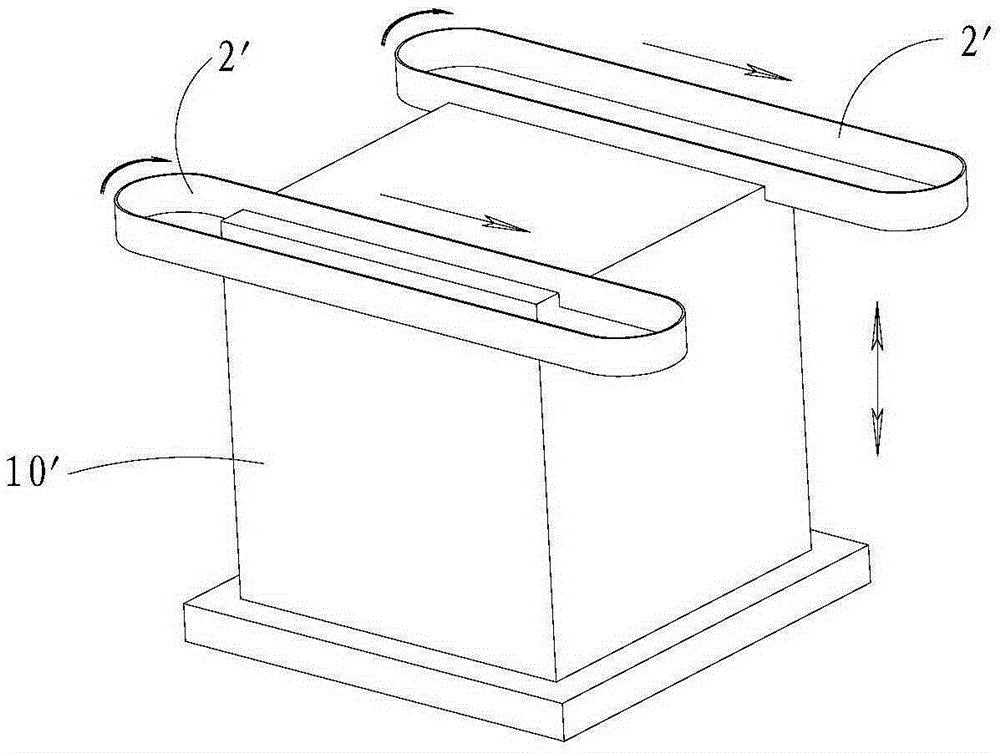

[0031] see attached image 4 to 7 As shown, a swing type marble multi-wire cutting machine, including the machine base 1 , located on the base 1 workbench 3 base 2 , located on the base 1 on the bench 3 upper mount 4 , mount 4 There is a wire cutting mechanism with multiple wire cutting wires 5 . base 2 with mount 4 At least one of these two parts is opposite the chassis 1 It is set up and down to realize the longitudinal feeding during cutting. In this example, the base 2 fixed on the base 1 upper, mount 4 Liftable on the machine base 1 on the base 1 There is also a mount for the drive on the 4 As for the lifting driving device (not shown in the figure), the above-mentioned lifting driving device can be driven by a ball screw. Here, the mount 4 There are also multiple sliders on the 14 ,Machine base 1 There is also a slider for use with the 14 mated to provide the mount 4 Linear guide that guides when ...

Embodiment 2

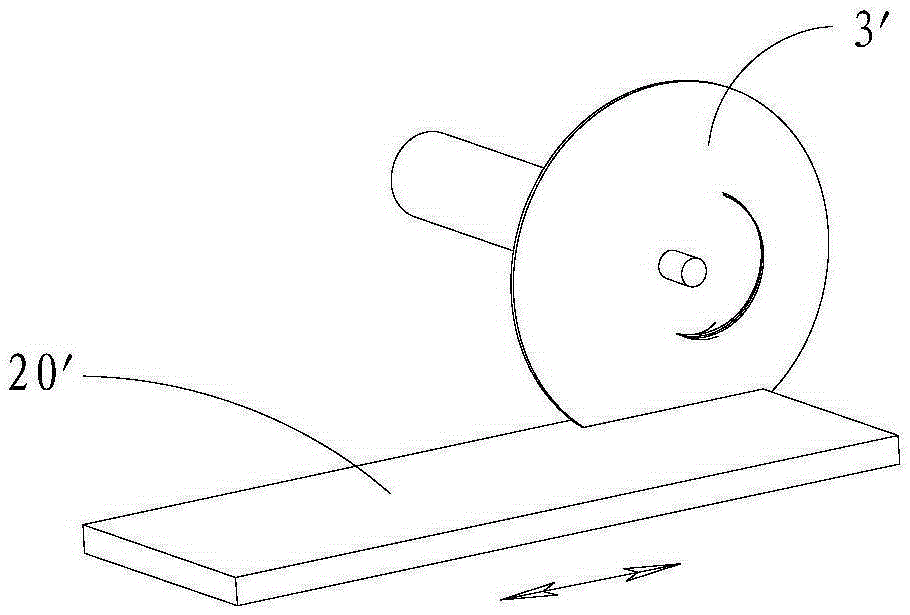

[0040] see picture 8 As shown, this embodiment and the embodiment 1 The difference is mainly in the way the swing device is set. In this embodiment, the swing device 7 Including vertically lifting on the base 2 jacking seat 71 , used to drive the jacking seat 71 The jacking drive device for lifting, the jacking seat 71 on the shaft 8 side of the workbench 3 One end of the connecting shaft 75 with jack seat 71 Phase rotation connection, adapter shaft 75 Axis and axis of rotation 8 axes are parallel to each other. Here, the jacking drive device includes a motor mounted on the base that can rotate around its axis 2 ball screw on 73 , and ball screw 73 Compatible screw nuts 72 , for driving the ball screw 73 A motor that rotates around its own axis 74 , lead screw nut 72 with jack seat 71 Phase fixed connection. Thus, when the motor 74 When working, the screw nut 72 Along the ball screw 73 The length direction of the lift drives the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com