Novel automobile part storage frame

A technology for placing auto parts and racks, which is applied to internal accessories, containers to prevent mechanical damage, containers, etc. It can solve problems such as no fixed management, falling, and damage to parts, so as to achieve reasonable placement, maximum storage capacity, and The effect of reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific embodiments.

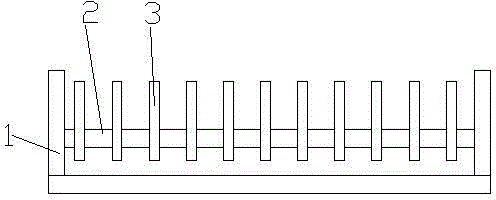

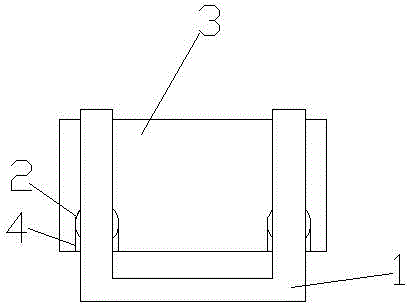

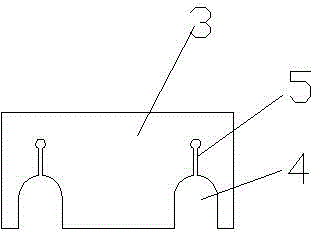

[0021] Such as Figure 1-3 As shown, a new type of rack for auto parts, including a support part 1, two circular frame rods 2 and a baffle plate 3, the support part 1 is in the shape of "Ц", and the two ends of the frame rods 2 are respectively fixed On the vertical plates at both ends of the support part 1, the baffle plate 3 is a rectangular plate, and one of its rectangular sides is respectively provided with two identical slots 4, and the slots 4 are in an inverted "U" shape. And a middle slit 5 is vertically opened at the top of the inverted "U"-shaped slot 4 .

[0022] In addition, the frame rod 2 is a plastic-coated round iron pipe. The baffle plate 3 is made of nylon. The opening width of the slot 4 is 2-4 mm smaller than the diameter of the rod 2 . Each frame bar 2 is provided with 5-30 said baffle plates 3 snapped on said frame bar 2 through said card slot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com