A metal workpiece phosphating device

A metal workpiece and storage box technology, applied in the direction of metal material coating process, etc., can solve the problems of uneven phosphating on the surface of the workpiece, uneven temperature of phosphating solution, and affecting the quality of phosphating, and achieve high temperature uniformity, The effect of preventing the quality reduction of phosphating and improving the uniformity of phosphating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

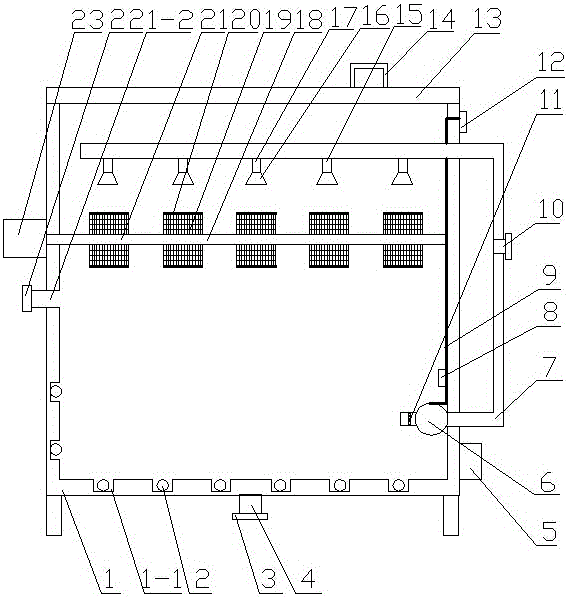

[0020] as attached figure 1 Shown: a metal workpiece phosphating device, including a phosphating tank 1, a heating pipe 2, a temperature control system 5, a temperature sensor 8, a self-priming pump 6, a spray system 15, and a placement mechanism 18.

[0021] The upper surface of the phosphating box 1 is provided with a box cover 13 hinged with the phosphating box 1, the box cover 13 can reduce the volatilization of the solvent in the phosphating box 1, and the box cover 13 is provided with a handle 13 to facilitate opening the box cover 13; The bottom of the phosphating box 1 is provided with a sewage channel 4 with the first cock 3, which is convenient for replacing the phosphating solution; the lower bottom surface and the side bottom in the phosphating box 1 are provided with a groove 1-1, and the heating tube 2 is placed in the groove. In the tank 1-1, prevent the heating tube 2 from being damaged; the side wall of the phosphating tank 1 is provided with an overflow port ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com