A hidden frame type ceramic sheet curtain wall

A ceramic thin plate, hidden frame technology, applied in the direction of walls, building components, buildings, etc., can solve the problem of metal fixed frame protruding, and achieve the effect of convenient and fast installation and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions and beneficial effects of the present invention will be clearer and more definite by further describing the specific embodiments of the present invention in conjunction with the accompanying drawings.

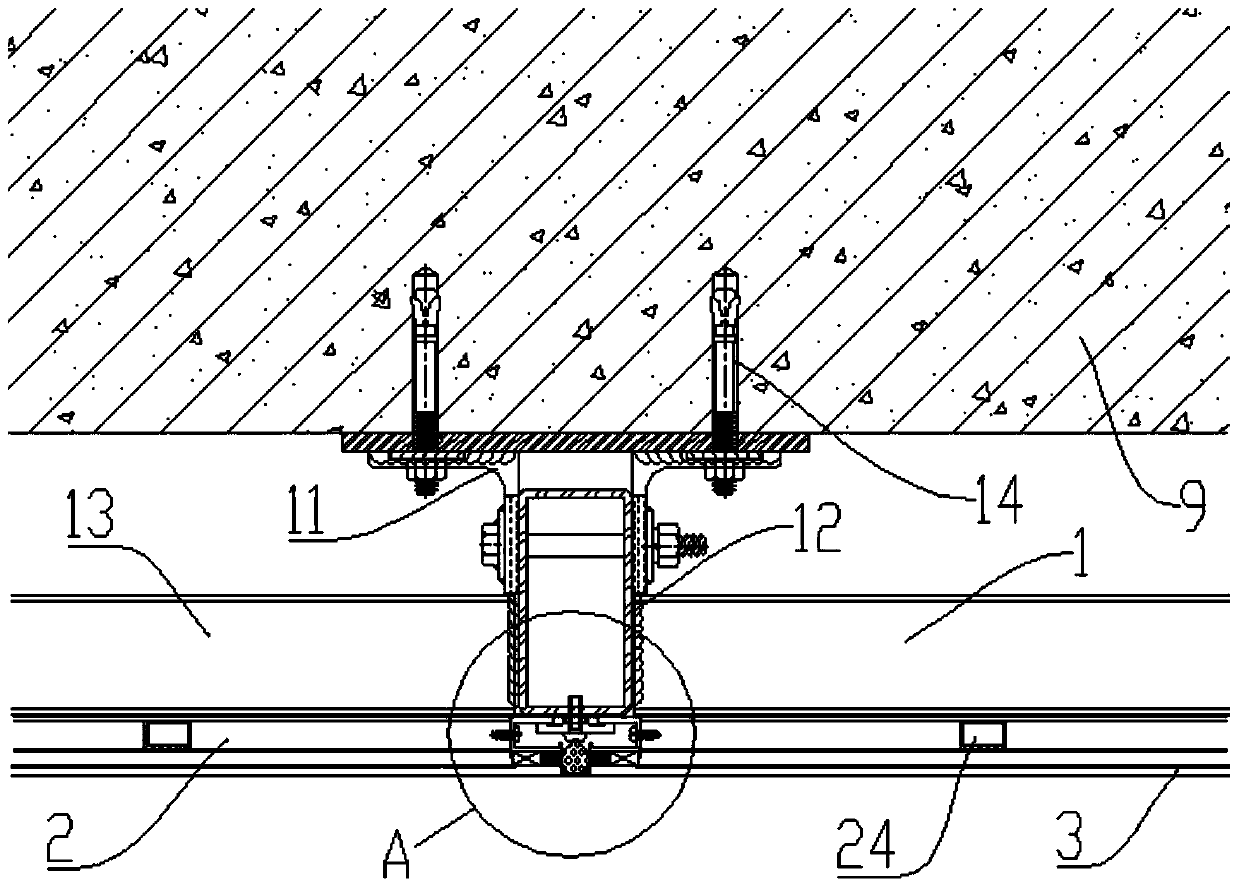

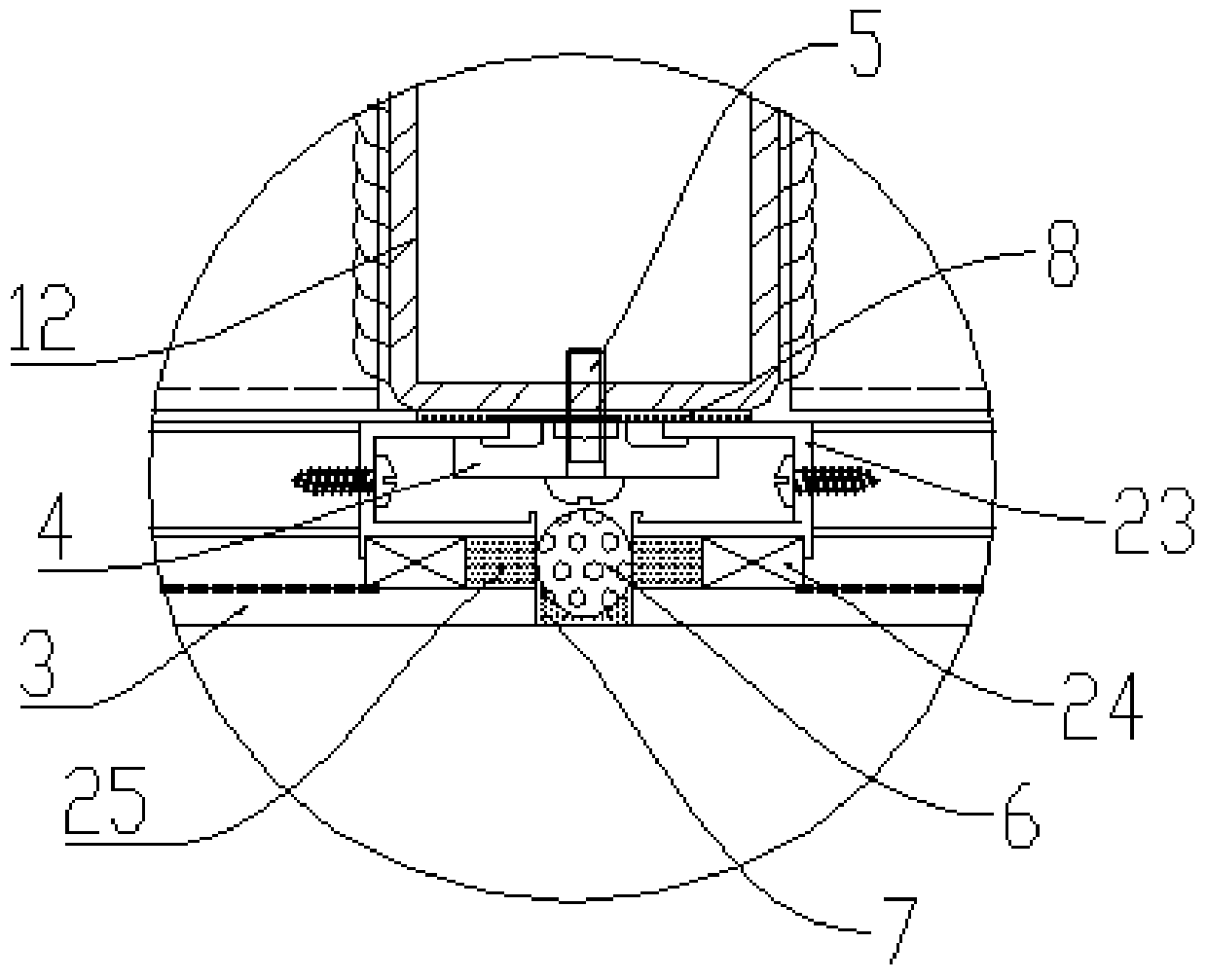

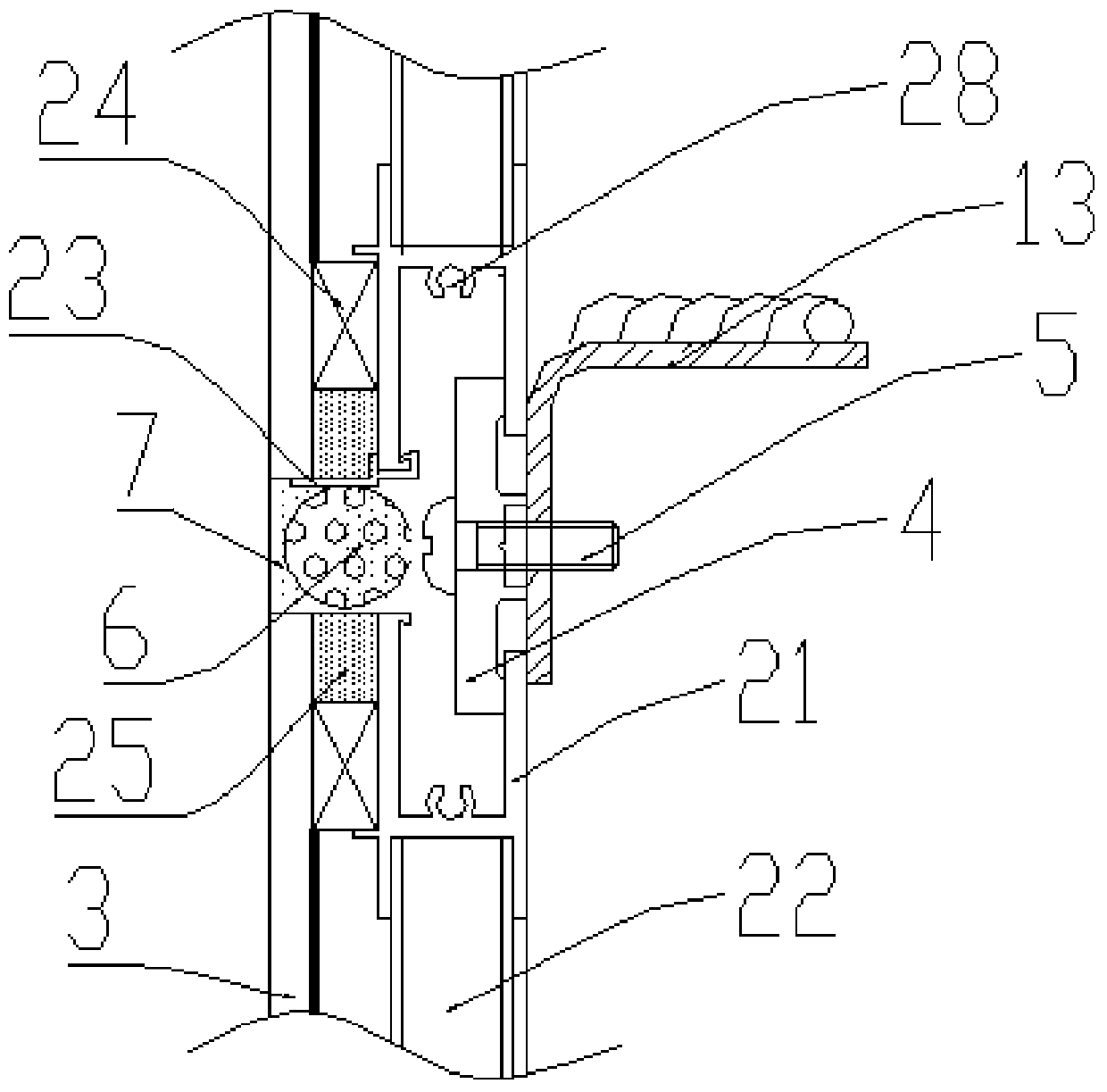

[0021] See attached Figures 1 to 4 , the present invention includes a wall fixing assembly 1 and a back frame assembly 2 installed on the wall fixing assembly 1, and a ceramic thin plate 3 is glued on the back frame assembly 2, and it is characterized in that: the back frame assembly 2 includes a working The font-shaped main back frame 21 and the auxiliary back frame 22 and supporting bar 23 arranged on the main back frame 21, the supporting bar 23 is located at the bottom of the entire back frame assembly 2, and the auxiliary back frame 22 is vertically arranged The adjacent back frame assembly 2 is fixed on the wall fixing assembly 1 through the pressure block 4 and the stainless steel screw 5; the gap between the adjacent back frame assembly 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com