High-outburst coal mine coal roadway drilling-loading-bolting integrated machine

An all-in-one machine and coal roadway technology, which is applied to the installation of bolts, mine roof brackets, mining equipment, etc., can solve problems such as bad working methods, low single entry level, and equipment evacuation, so as to achieve strong drilling adaptability and ensure safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

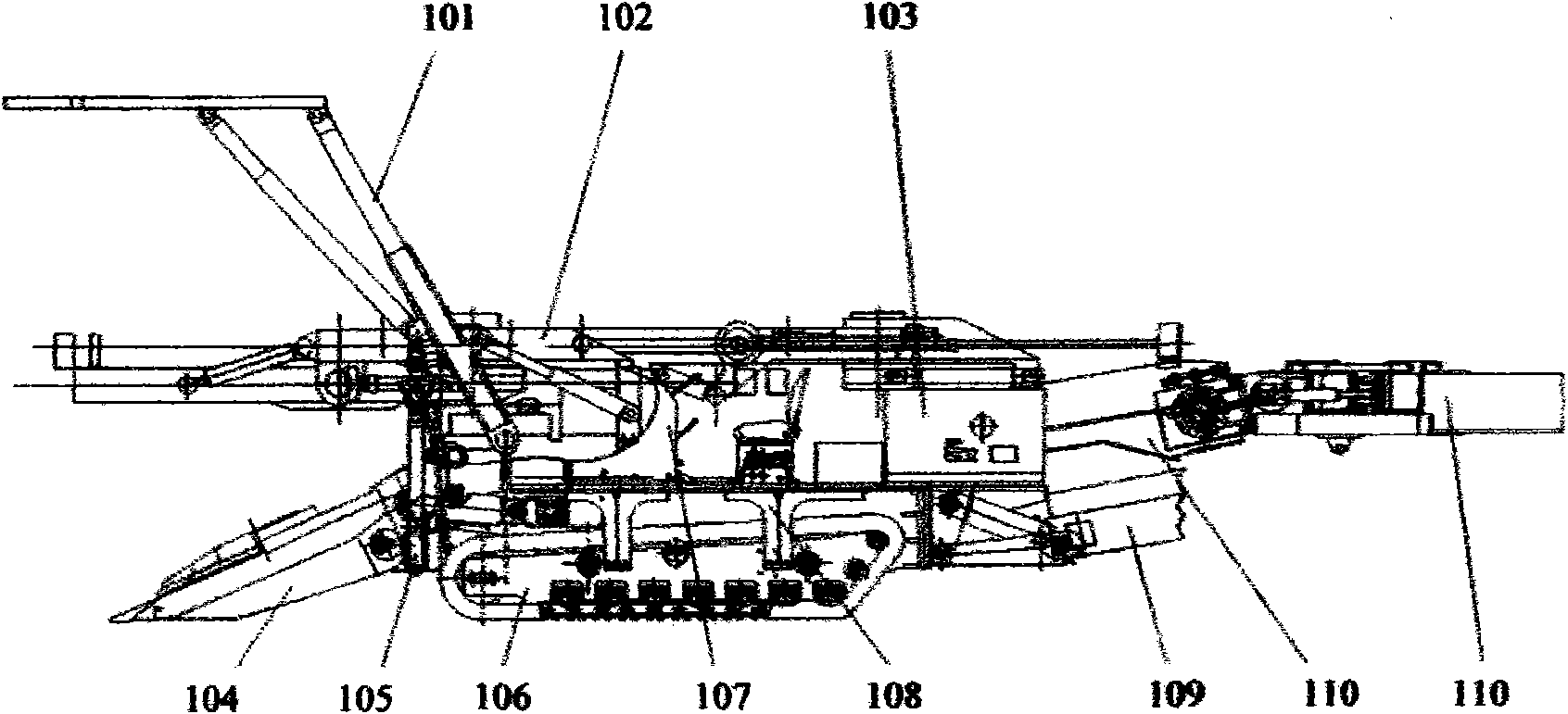

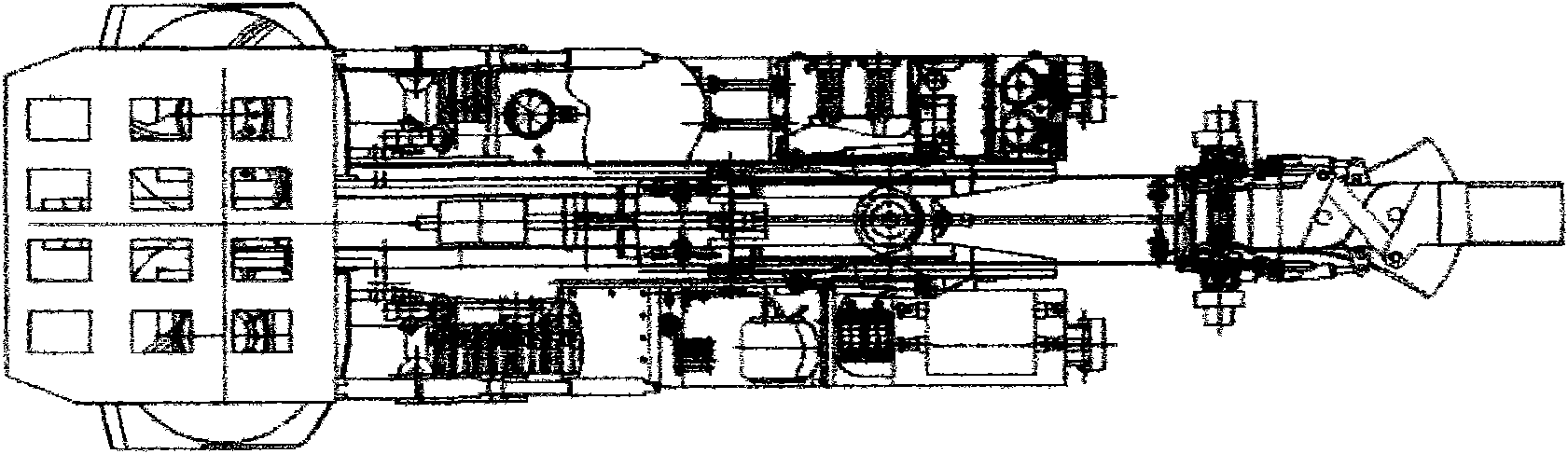

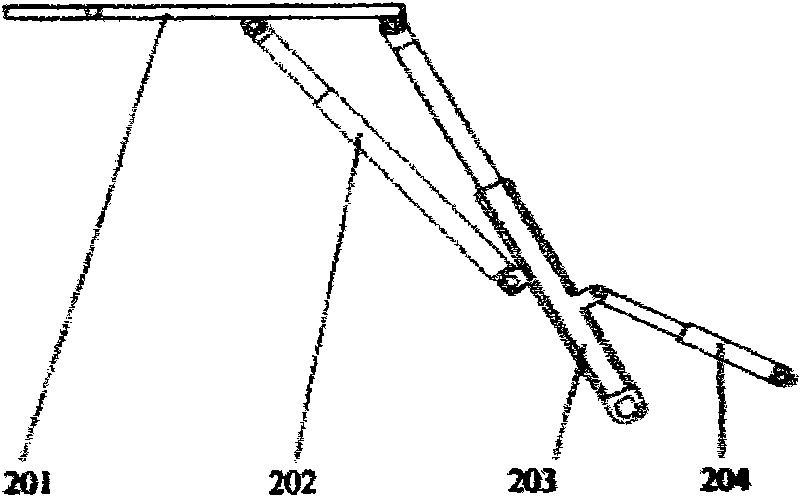

[0016] Figure 1A-1B They are the front view and top view structural diagrams of the all-in-one machine for drilling, installing, anchoring, supporting and transporting coal lanes in high-outburst mines according to the present invention. Temporary support 101, airborne anti-outburst drilling rig 102, electric control system 103, loading unit 104, airborne bolter rig 105, traveling device 106, operating console 107, main frame 108, rear support assembly 109, scraper conveyor 110 , discharge port reversing device 111, fuel tank pumping station and motor (not shown in the figure). Among them, the main frame 108 is a frame structure, and the front part of the main frame 108 is provided with a hydraulic roof temporary support for the roof support operation, and the airborne anti-outburst drilling machine 102 used for deep drilling operatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com