Steel beam bolting joint structure of horizontal cross-core plate type concrete-filled steel tubular column

A technology of steel tube concrete column and node structure, which is applied in the direction of building structure and construction, can solve the problems of affecting aesthetics, difficult construction, large steel consumption, etc., and achieve the goal of ensuring aesthetics, reasonable force, and improving bearing capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

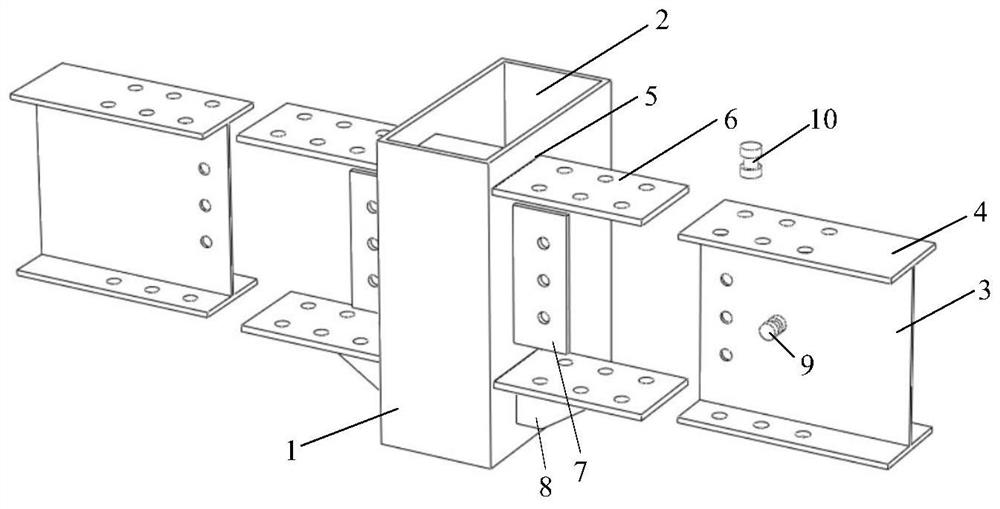

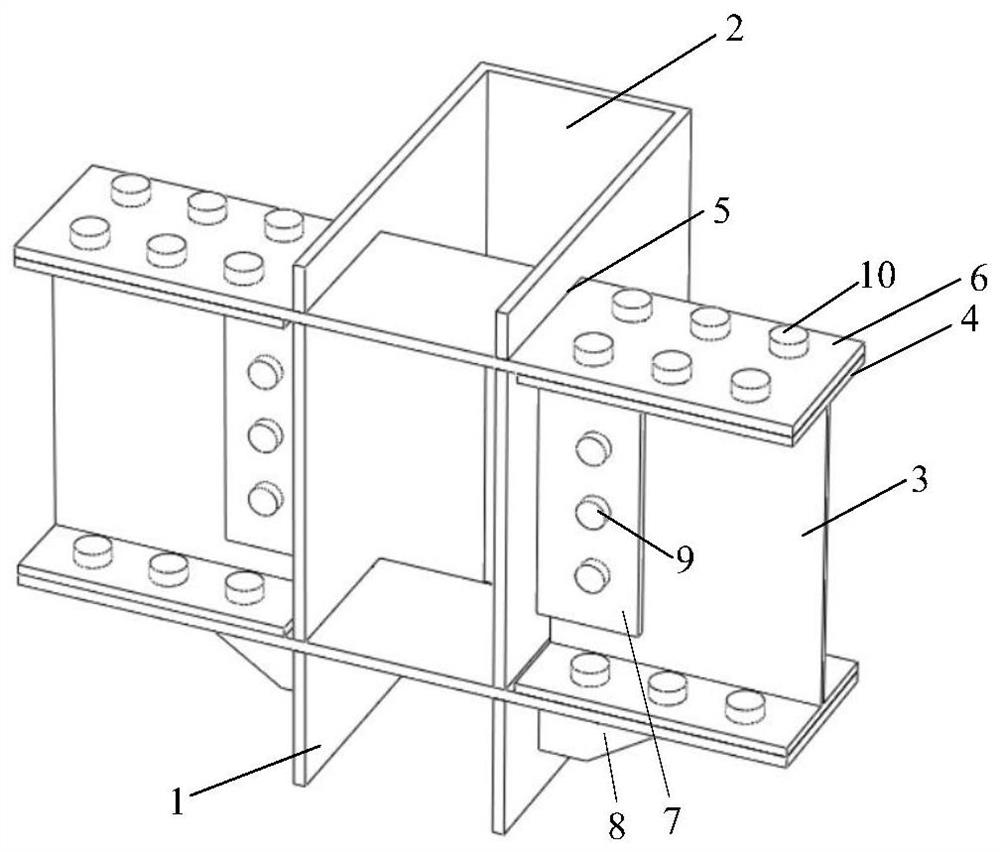

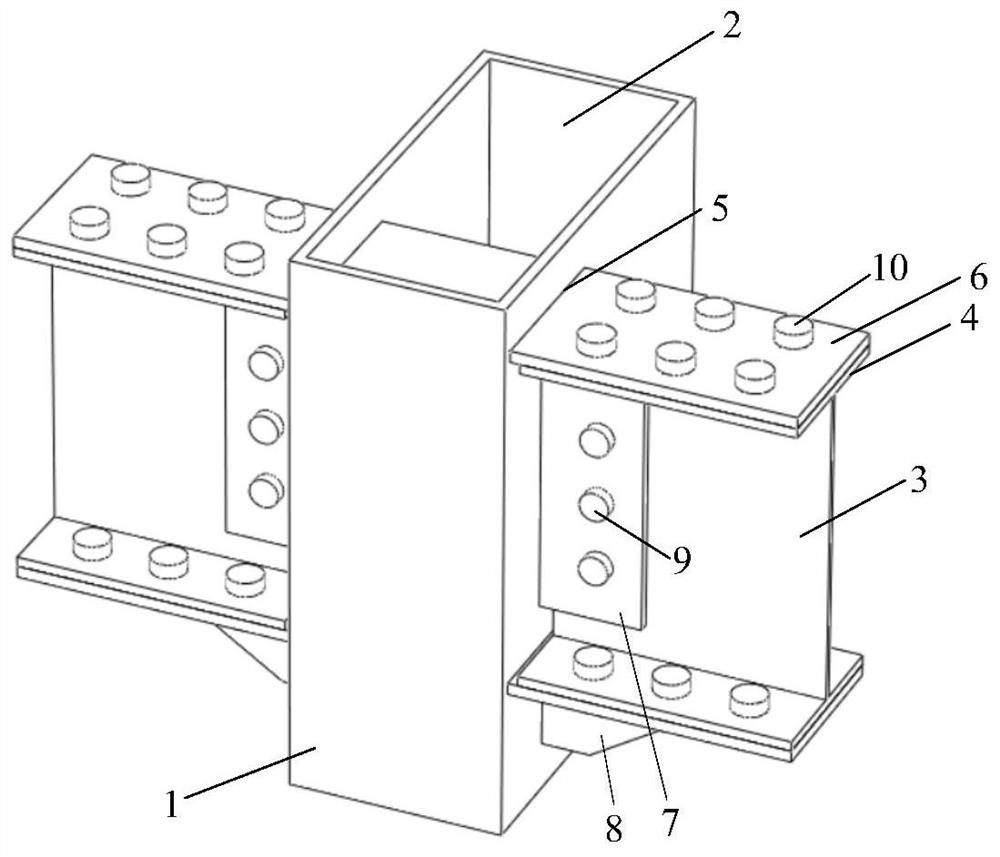

[0017] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0018] refer to Figure 1-3 , the steel beam bolted joint structure of the horizontal core-through slab concrete-filled steel tube column, including the outer steel tube 1 and the inner concrete tube 2, the outer steel tube 1 and the inner tube concrete 2 form a steel tube concrete column, and the long side of the outer peripheral surface of the outer steel tube 1 corresponds to A horizontal long groove 5 is opened at the steel wing, and a horizontal through-core plate 6 is set through the horizontal long groove 5 along the short side of the outer steel pipe 1, and is connected with the outer steel pipe 1 by welding; the horizontal through-core plate 6 on the same sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com