Tube plate combining mechanism, refrigerating unit and air conditioner

A technology for refrigeration units and air conditioners, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of wasting materials, reducing unit assembly efficiency, and failing to ensure unit consistency, so as to reduce material waste and ensure consistency. , The effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

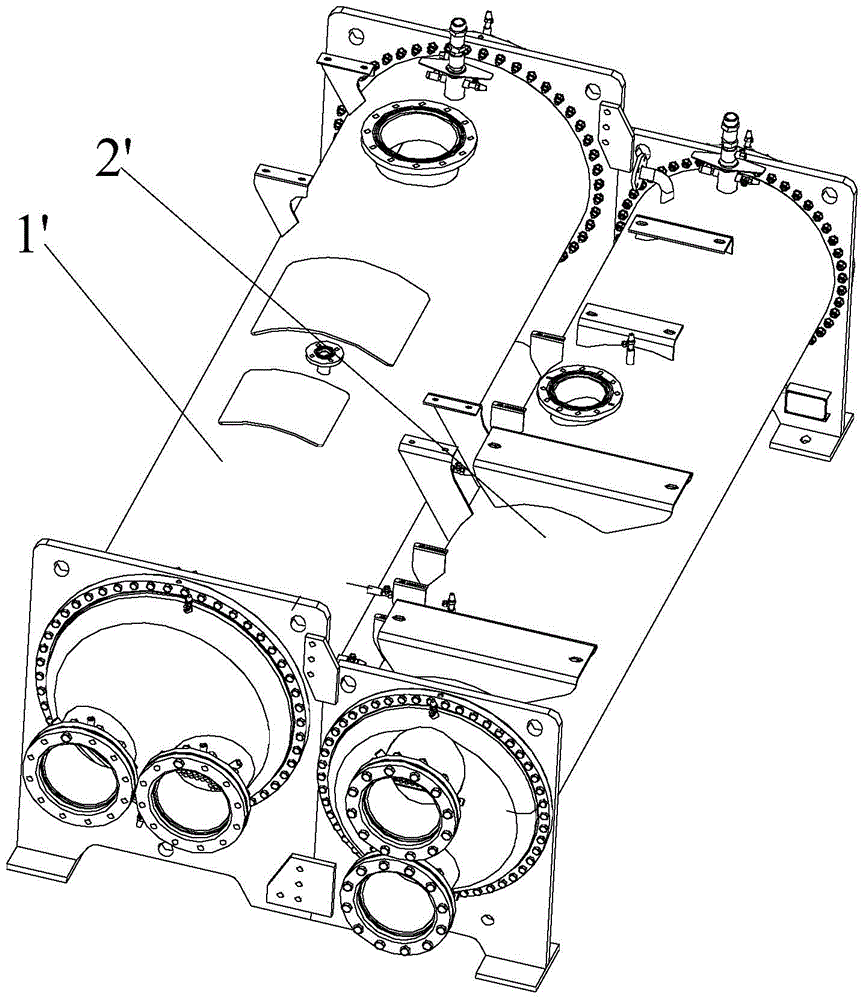

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

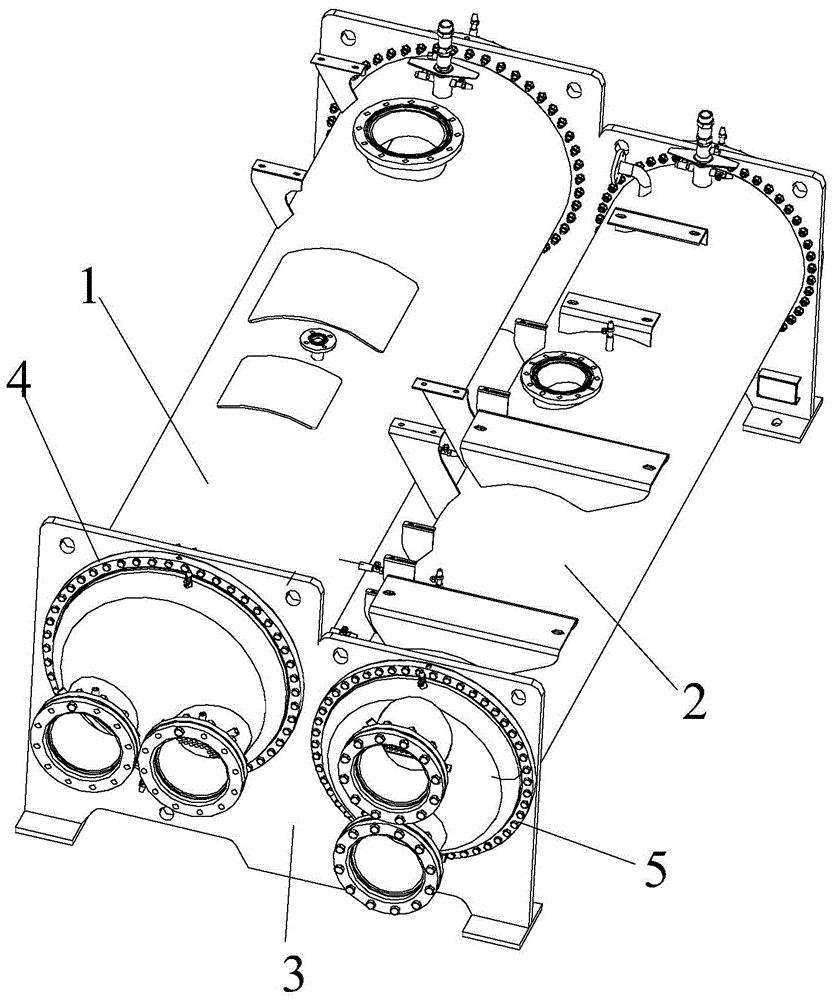

[0019] see figure 2 As shown, according to the embodiment of the present invention, the tube sheet merging mechanism includes an evaporator 1 and a condenser 2 arranged side by side, at least one end of the evaporator 1 and the condenser 2 is provided with an integral positioning tube sheet 3, and the integral positioning tube sheet 3 is provided with a first installation and positioning hole 4 and a second installation and positioning hole 5, the evaporator 1 is positioned and installed on the first installation and positioning hole 4, and the condenser 2 is positioned and installed on the second installation and positioning hole 5.

[0020] When assembling the air conditioner, the evaporator 1 and the condenser 2 can be fixed together on the integral positioning tube sheet 3, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com