Fast-loading canister shot drum magazine

A technology of shot and drum, applied in the field of firearms, can solve the problems of stuck ammunition, only the same model can be transported, etc., and achieve the effect of increasing the capacity of ammunition, reducing the type and number, and reducing friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The invention can achieve the purposes of increasing the capacity of the shotgun drum, reducing the volume of the shotgun drum, ensuring reliable loading and the like.

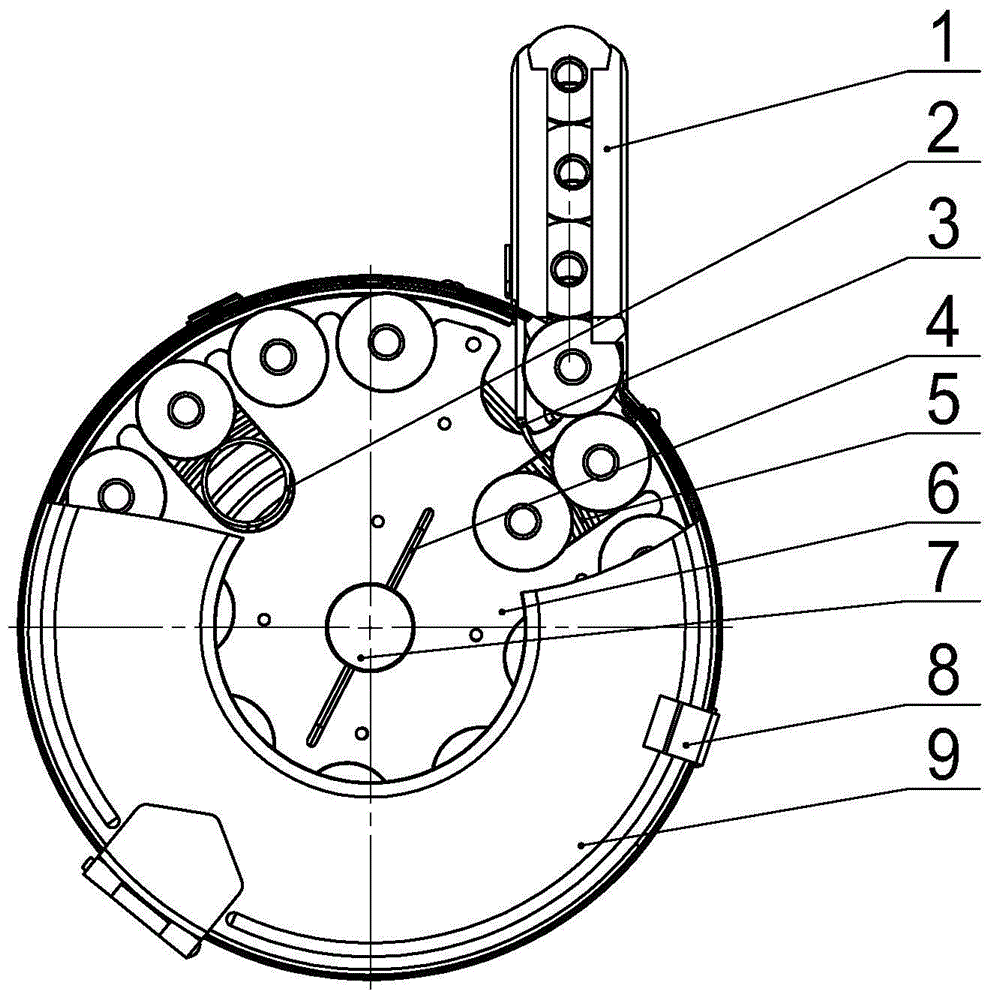

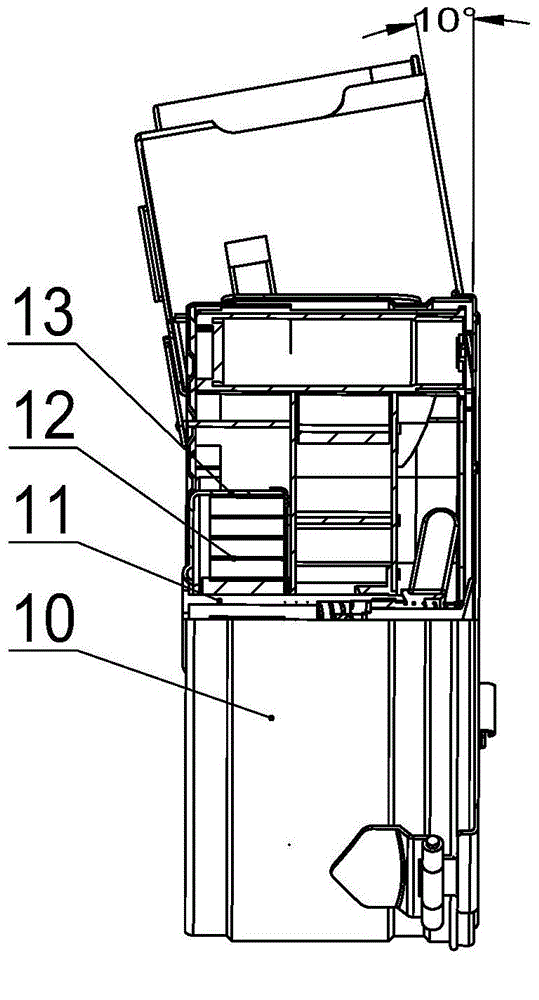

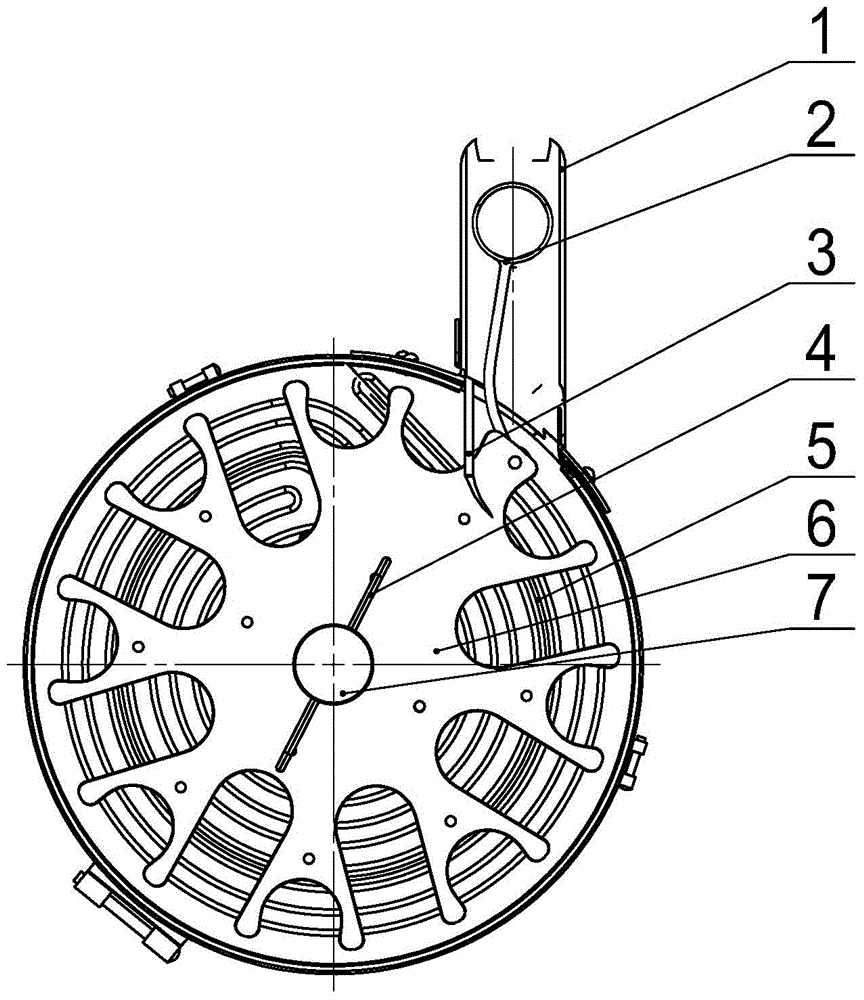

[0023] Such as figure 1 with figure 2 As shown, a quick-loading shotgun drum of the present invention includes a drum body 10, a rail plate 5, a mandrel 11, a torsion spring seat 13, a torsion spring 12, a dial wheel 6, a drum cover 9, a push plug 2, Plucking plate 3, bullet outlet body 1 and ratchet mechanism.

[0024] The drum body 10 has a cylindrical structure, and one end of the ejection mouth body 1 is fixed on the drum body 10, and ensures that the direction of the shot in the ejection port body 1 is consistent with the direction of the shot in the drum body 10. When the present invention is used, the bullet outlet body 1 is located in the shotgun casing, and the mouth at the other end of the bullet outlet body 1 corresponds to the bolt head. The structure of the bullet outlet body 1 is consi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com