Spare parts stock risk decision evaluation method based on differentiation holding cost

A cost-of-holding and risk-based decision-making technology, applied in the direction of instruments, data processing applications, resources, etc., can solve unreasonable problems and achieve accurate calculation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

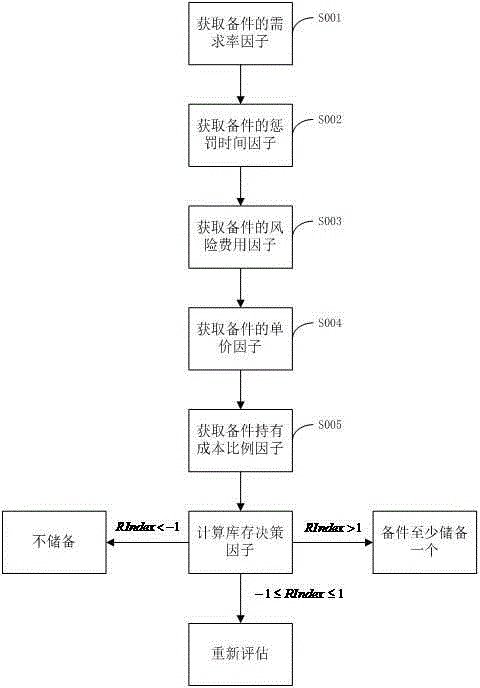

Method used

Image

Examples

Embodiment 1

[0079] After collecting relevant data for a certain type of bearing in a CNPC company, the following data were confirmed:

[0080] The demand rate factor for this bearing is -1;

[0081] The penalty cost time factor for this bearing is -2;

[0082] The penalty cost factor for this bearing is 0;

[0083] The unit price factor of this bearing is 4;

[0084] The holding cost factor for this bearing is 1;

[0085] When the differential holding cost proportional factor is not introduced, the spare parts inventory decision factor is RIndex=-1+(-2)+0+4=1, the spare parts inventory decision cannot be determined, and it needs to be re-evaluated to confirm whether it needs to reserve.

[0086] However, after adopting the present invention to introduce a differentiated spare parts holding cost factor, the decision factor RIndex=-1+(-2)+0+4+1=2, and the result after evaluation is that it is recommended to reserve at least one bearing.

[0087] After introducing the differentiated spar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com