Double-winding motor stator

A motor stator, double winding technology, applied in the shape/pattern/structure of winding insulation, the shape/pattern/structure of winding conductor, the shape/pattern/structure of magnetic circuit, etc., can solve asymmetry, two sets of windings cannot be independent Resistance and other problems, to achieve the effect of small resistance difference, meet the requirements of resistance symmetry, and ensure consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

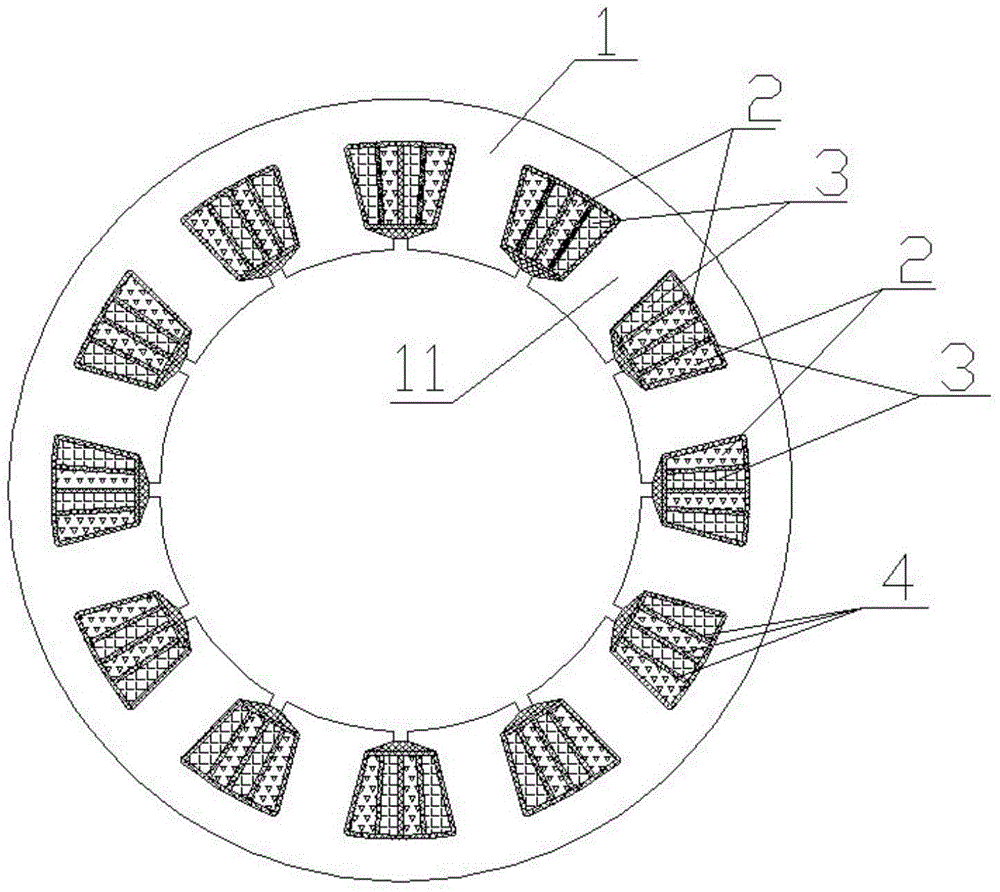

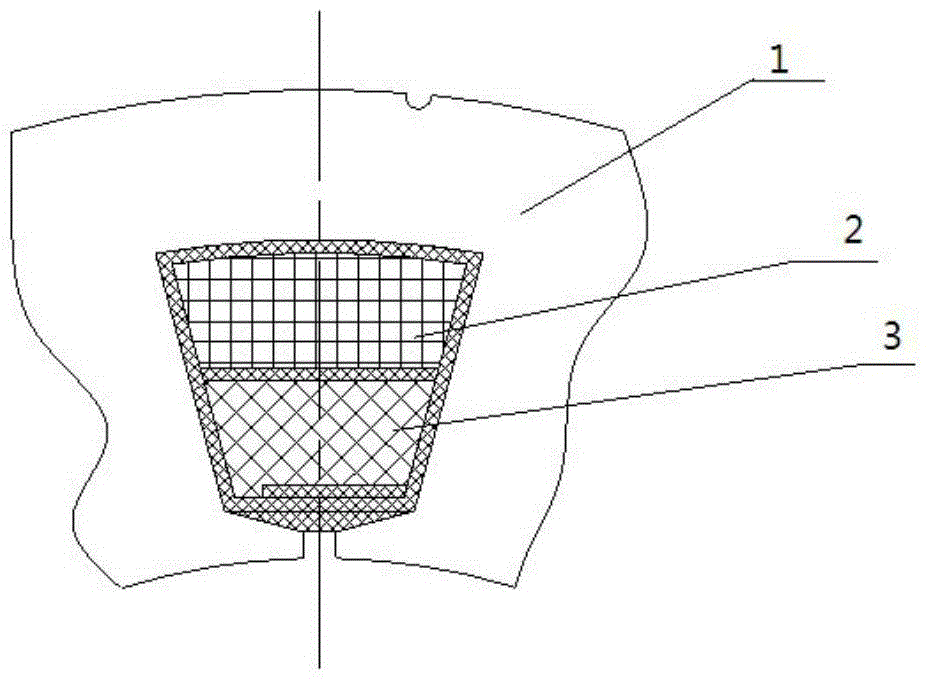

[0015] Such as figure 1 The stator of a double-winding motor shown includes a stator body 1, a winding A2, a winding B3 and an insulating layer 4. The stator body 1 is a concentrated winding structure, and the number of slots of the stator body 1 is an even number of slots; Each tooth portion 11 of the stator body 1 is wound with a winding A2 and a winding B3, and the inner and outer layers of the winding A2 and the winding B3 on two adjacent tooth portions 11 are alternately wound, and the winding A2 and the winding B3 in each slot They are all separated by an insulating layer 4; the insulating layer 4 is a polyimide film. In this structure, winding A2 and winding B3 are required to be wound on the same tooth part 11 at the same time. If the winding A2 of the previous tooth part 11 is wound on the inner layer and the winding B3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com