Permanent magnet motor double-key-groove rotor punching sheet capable of being used at multiple angles

A technique for punching permanent magnet motors and rotors, which is applied to magnetic circuit rotating parts, electrical components, electromechanical devices, etc., can solve the problems of making and installing punches that cannot be simplified, and achieve saving inventory costs and manufacturing hours, The effect of reducing the weight of the rotor and simplifying the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

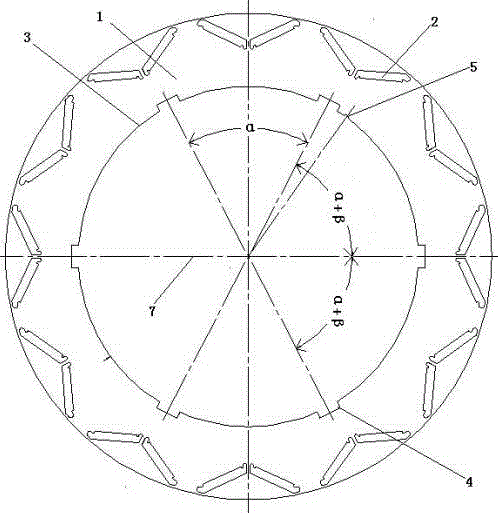

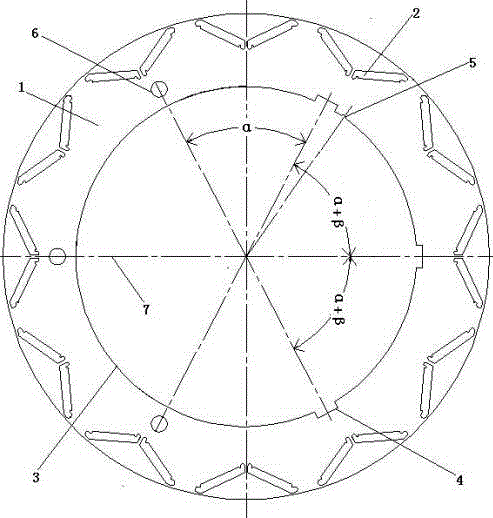

[0015] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

[0016] Such as figure 1 As shown, a permanent magnet motor double-key slot rotor punching plate that can be used at multiple angles includes: punching plate 1, a number of punching slots 2 are arranged near the outer periphery of punching plate 1, and a shaft hole 3 is opened in the center of punching plate 1 , the inner circle of the shaft hole 3 is provided with several key slots 4, and the other side of the center symmetry of each key slot 4 is provided with another key slot 4, and a connecting line is formed between the centrally symmetrical key slots 4. The punching sheet 1 is divided into sectors with different angles and sizes, and a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com