Electrochromic mirror

An electrochromic, electrochromic layer technology, applied in the direction of optics, instruments, optical observation devices, etc., to achieve the effect of ensuring insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

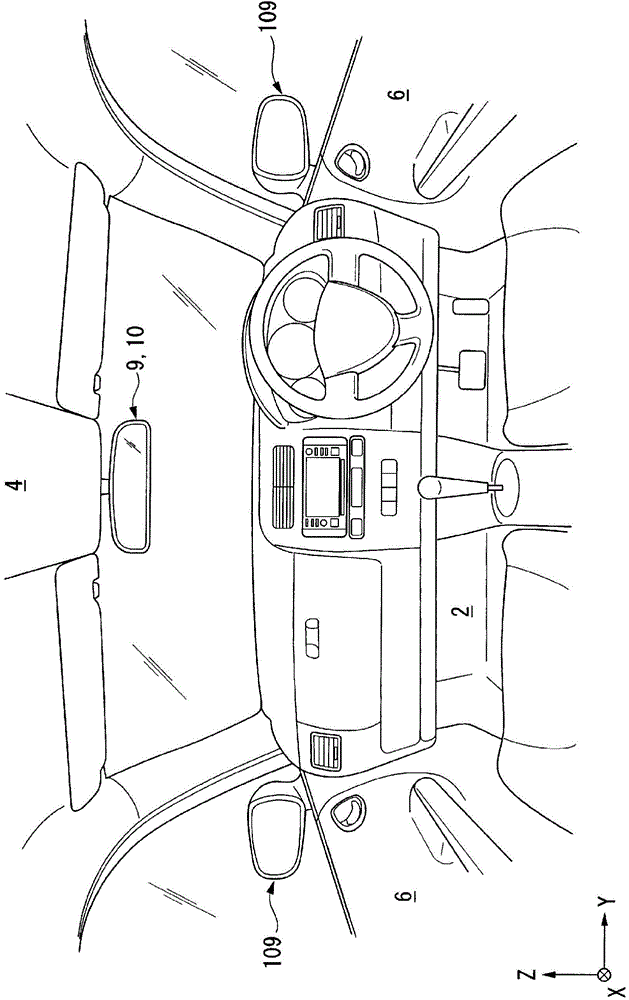

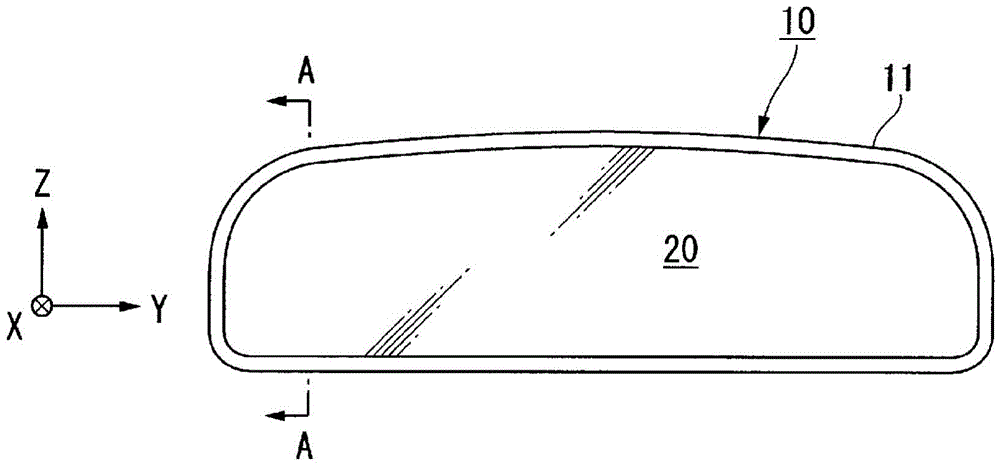

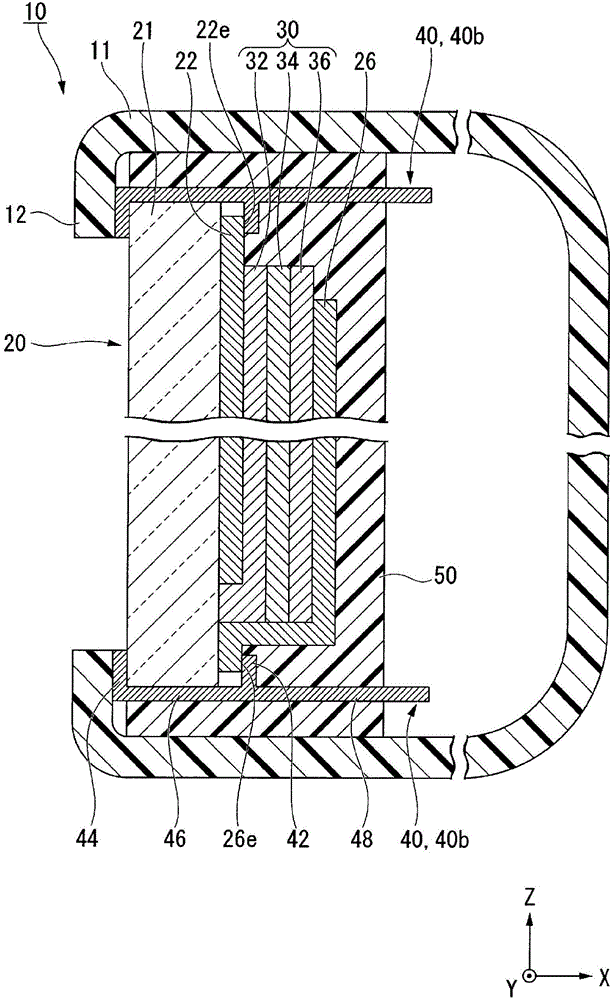

[0036] figure 2 It is a front view of the EC mirror 10 of the first embodiment. image 3 is an explanatory diagram of the EC mirror 10 of the first embodiment, and is figure 2 A sectional view at line A-A of . Such as image 3 As shown, the EC mirror 10 includes an EC mirror body 20, a power supply terminal 40 for supplying power to the EC mirror body 20, an ion insulating material 50 covering the EC mirror body 20, and a mirror holder 11 supporting the EC mirror body 20. . The EC mirror main body 20 is formed by sequentially laminating a transparent electrode film 22 , an EC layer 30 that develops color by voltage application, and a reflective electrode film 26 on the +X surface (first surface) of a transparent substrate 21 .

[0037] The transparent substrate 21 is formed of a material (glass, etc.) having visible light permeability. The transparent electrode film 22 is formed of a material (ITO, etc.) having visible light permeability and conductivity to a thickness ...

no. 2 approach

[0083] Figure 11 is an explanatory diagram of the EC mirror 210 of the second embodiment, and is the same as figure 2 A cross-sectional view of a portion corresponding to line A-A. image 3 The shown EC mirror 10 of the first embodiment has the projecting portion 22e of the transparent electrode film 22 formed on the +Z side of the EC layer 30, and the projecting portion 22e of the reflective electrode film 26 is formed on the −Z side of the EC layer 30. Section 26e. in comparison, Figure 11 The EC of the second embodiment shown differs from the first embodiment in that the reflecting mirror 210 includes the entirety of the EC layer 30 inside the transparent electrode film 22 and includes the entirety of the reflective electrode film 26 inside the EC layer 30 . In addition, the detailed description of the part which has the same structure as 1st Embodiment is abbreviate|omitted.

[0084] Such as Figure 11 As shown, in the EC mirror 210 , the transparent electrode film 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com