Fixed wiring device for anti-plating insulated bundle

A wiring device and clustering technology, applied in the direction of connection insulation, multi-conductor connectors, etc., can solve the problems of cable entanglement space, short circuit or breakdown, occupation, etc., to reduce cable entanglement, reduce space occupation, and ensure insulation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following is a detailed description of the anti-plating insulation bundled fixed wiring device of the present invention in conjunction with the drawings and embodiments of the specification:

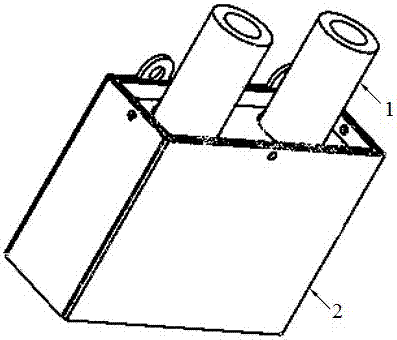

[0026] Such as Figure 1~5 As shown, an anti-plating insulation cluster fixed wiring device includes a fixed assembly 2 and an anti-plating assembly 1 placed in the fixed assembly 2;

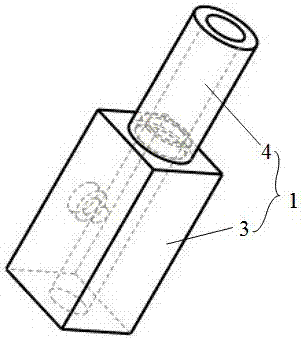

[0027] The anti-plating assembly 1 is composed of a ceramic base 3 and a ceramic sleeve 4; the ceramic base 3 is a cuboid structure with a through hole 31 formed in the middle, an annular boss 32 is formed on the upper end surface, and a small hole 33 is formed on the side wall; the ceramic sleeve The tube 4 is a cylindrical structure with a stepped hole 41 formed in the middle; the boss 32 is inserted into the large-diameter end of the stepped hole 41;

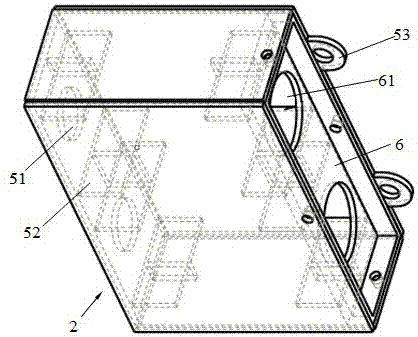

[0028] The fixing assembly 2 is a hollow cuboid structure composed of a mounting base 5 and a detachable mounting cover 6 ; two wiring holes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com