A reliable welding method for a direct insertion type metal packaging circuit module

A technology of metal packaging and circuit modules, which is applied in the direction of assembling printed circuits with electrical components, can solve problems such as damaged modules and abnormal module functions, and achieve the effect of ensuring insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] A reliable welding method for an in-line metal-encapsulated circuit module provided by the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

[0023] A method for reliable welding of in-line metal package circuit modules provided by the present invention comprises the following steps:

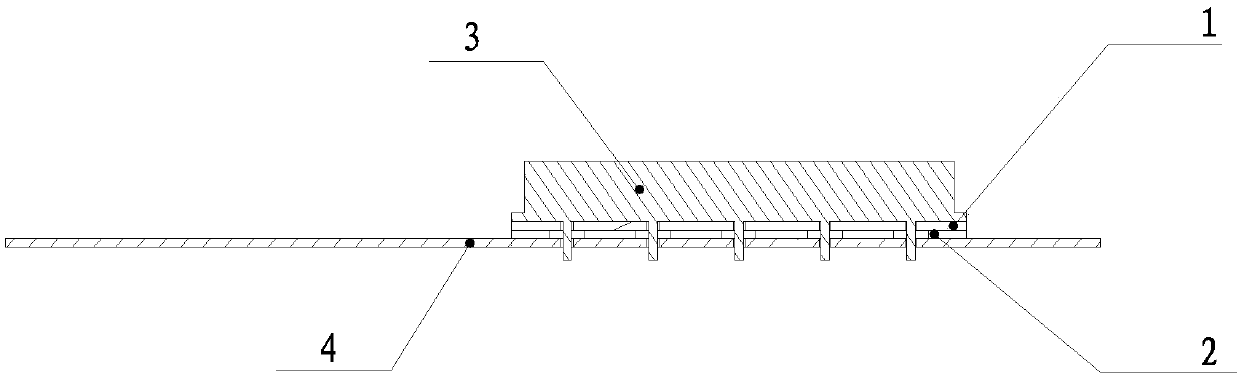

[0024] Step 1, such as image 3 As shown, before soldering, a thermally conductive insulating pad with a special structural design is placed between the in-line metal package circuit module 3 and the printed circuit board 4. The thermally conductive insulating pad adopts a double-layer structure, including a thermally conductive insulating pad One 1 and heat conduction insulation mat two 2, use a heat conduction insulation mat with a silicon rubber base material of 0.25 mm thickness, and the superposition height of the two layers is 0.5 mm.

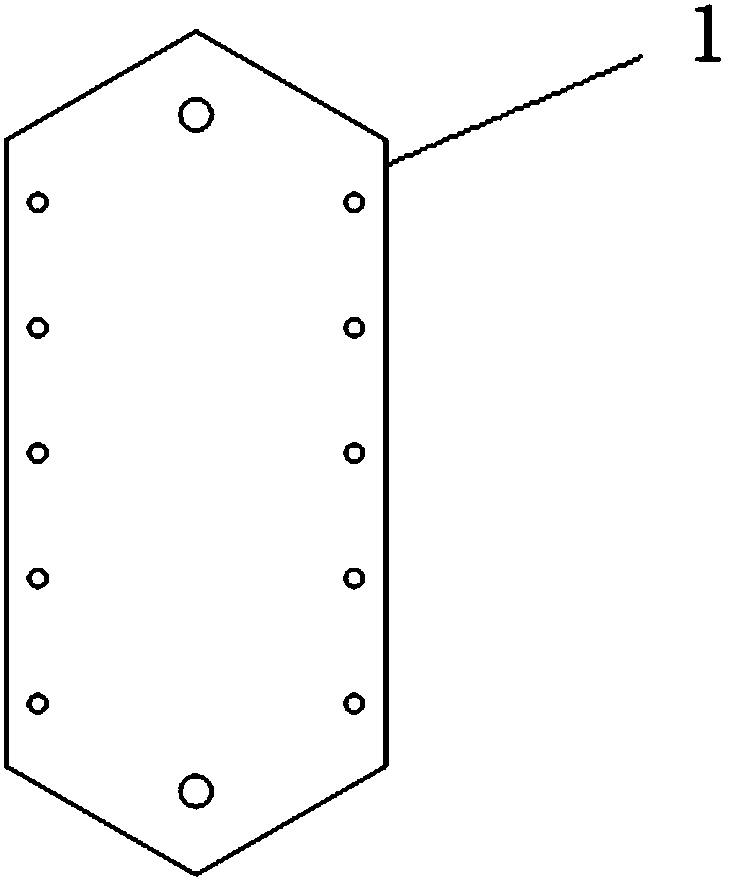

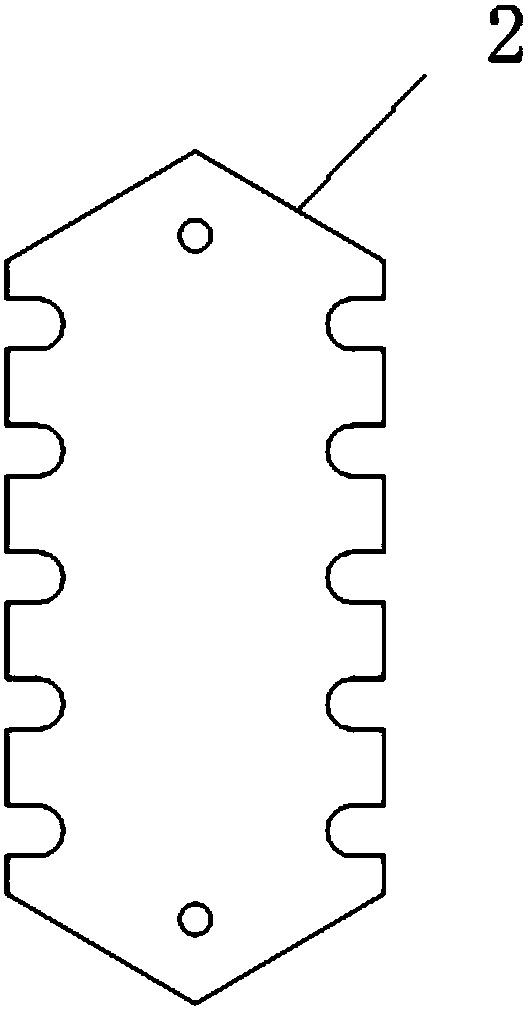

[0025] like figure 1 As shown, the heat-conducting insulating pad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com