Riding rice transplanter or paddy field operation machine

A working machine and paddy field technology, applied in agriculture, transplanting machinery, planting methods, etc., can solve problems such as operation cable interference, and achieve the effect of preventing and inhibiting aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0095] Embodiments of the present invention will be described below with reference to the accompanying drawings.

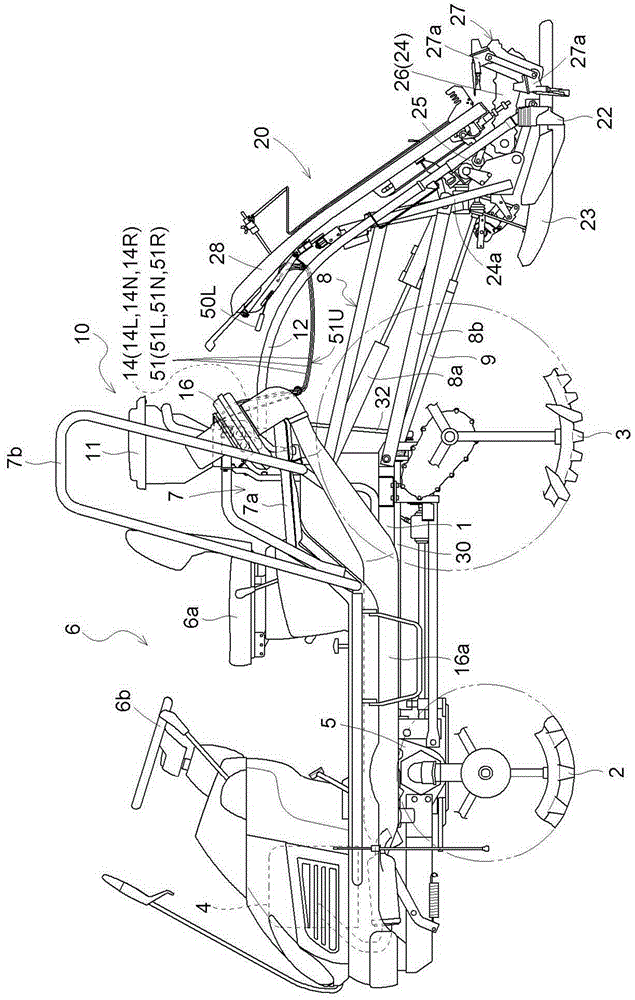

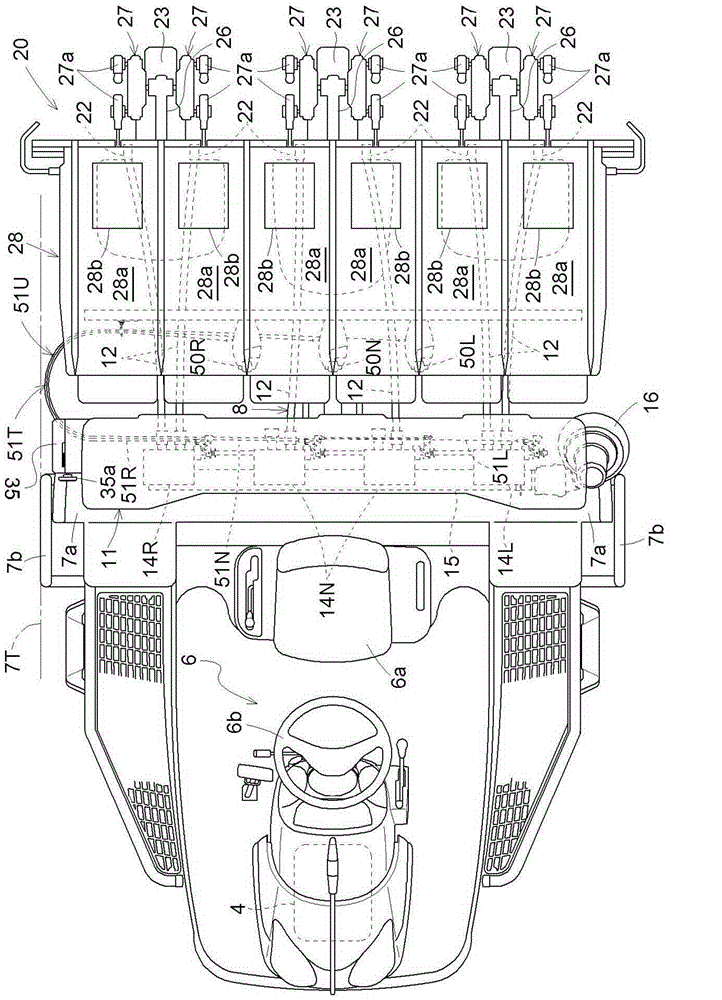

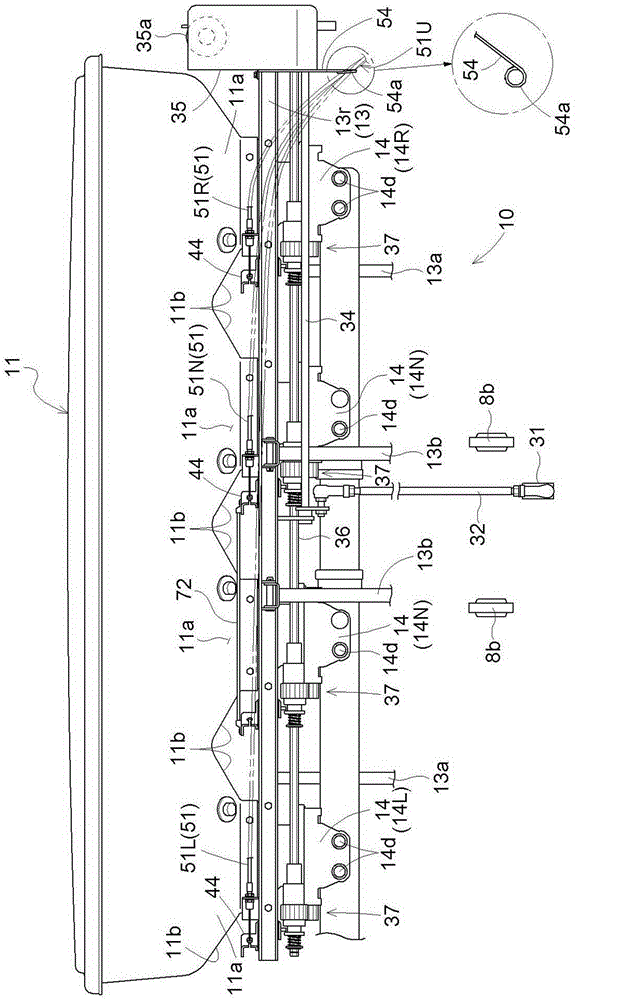

[0096] figure 1 It is a side view showing the whole of the riding-type rice transplanter or paddy field working machine according to the embodiment of the present invention. figure 2 It is a plan view which shows the whole of the riding-type rice transplanter or paddy field work machine which concerns on the Example of this invention. Such as figure 1 , 2 As shown, the ride-on rice transplanter or paddy field operation machine of the embodiment of the present invention has an automatic traveling vehicle, and the lower part of the vehicle body frame 1 of the automatic traveling vehicle is equipped with a pair of left and right front wheels 2, 2 and a pair of left and right rear wheels. 3, 3. The rear portion of the self-propelled vehicle is equipped with a powder or grain supply device 10 , and the powder or grain supply device 10 has a powder or grain body bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com