Food heating and mixing bucket with sensor

A technology of heating, stirring and sensors, applied in confectionary, confectionary industry, food science, etc., can solve the problems of cumbersome and complicated operation procedures and waste of time, achieve the effect of reducing processing procedures, reducing production and processing steps, and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

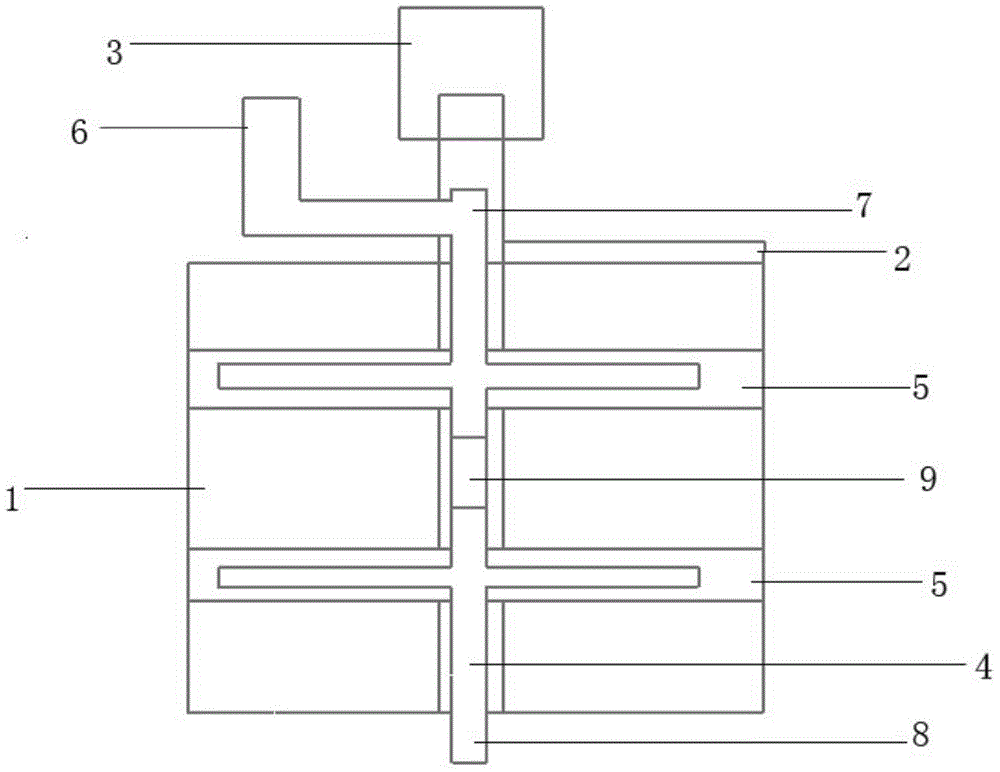

[0012] Such as figure 1 As shown, a food mixing bucket includes a bucket body 1 and a bucket cover 2. A motor 3 is provided outside the bucket body 1. The motor 3 is connected to a rotating shaft 4. The rotating shaft 4 goes deep into the inside of the bucket body 1. The rotating shaft 4 is distributed with stirring rods 5. , the barrel body 1 is provided with an air inlet 6 outside, the air inlet 6 is connected to the air pipe 7, the air pipe 7 is arranged inside the rotating shaft 4 and the stirring rod 5, the bottom end of the air pipe 7 is provided with an air outlet 8, and the barrel cover 2 is arranged on the barrel body 1, on the upper end side, a temperature sensor 9 is provided on the inner rotating shaft 4 of the barrel body 1.

[0013] When in use, open the barrel cover 2, put the candy raw materials into the barrel body 1, connect the motor 3, the motor 3 drives the rotating shaft 4 to rotate, and the rotating shaft 4 drives the stirring rod 5 to rotate, and the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com