A waste removal device for an unwinding die-cutting machine

A die-cutting machine and waste removal technology, applied in metal processing and other directions, can solve the problems of increased manufacturing cost, frequent start and stop, a lot of labor, etc., to increase automatic material receiving settings, reduce production and processing procedures, and maintain constant torque linearity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

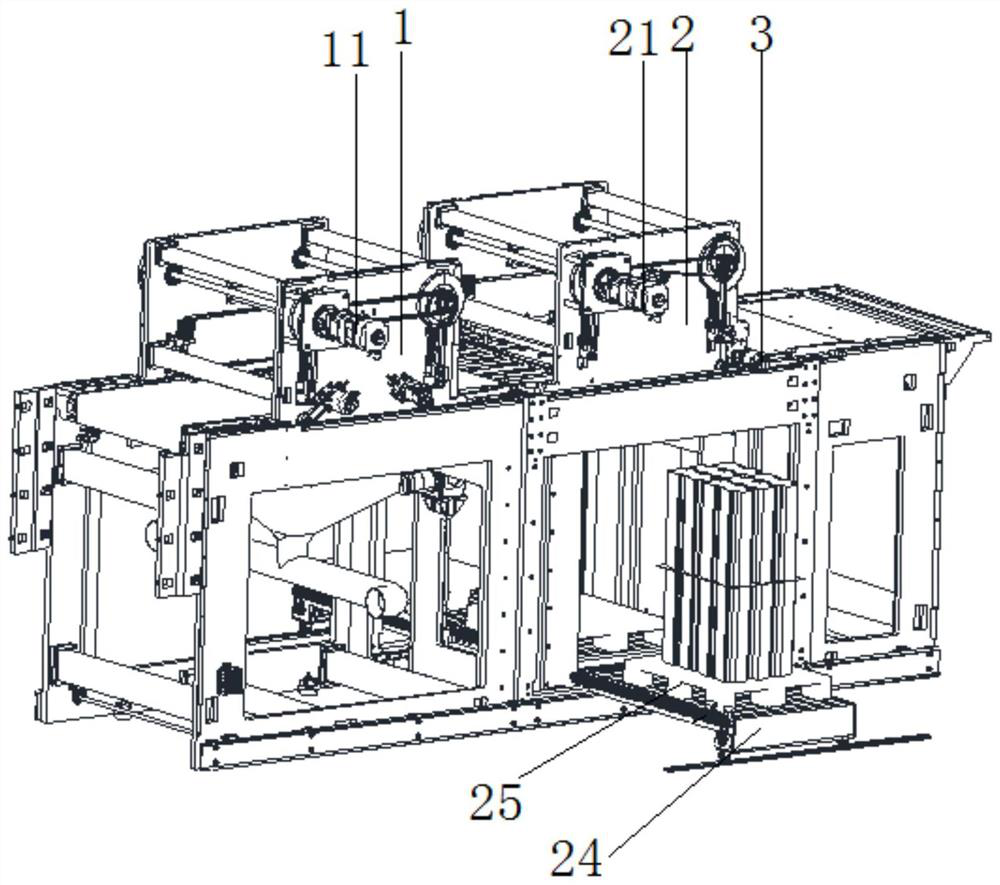

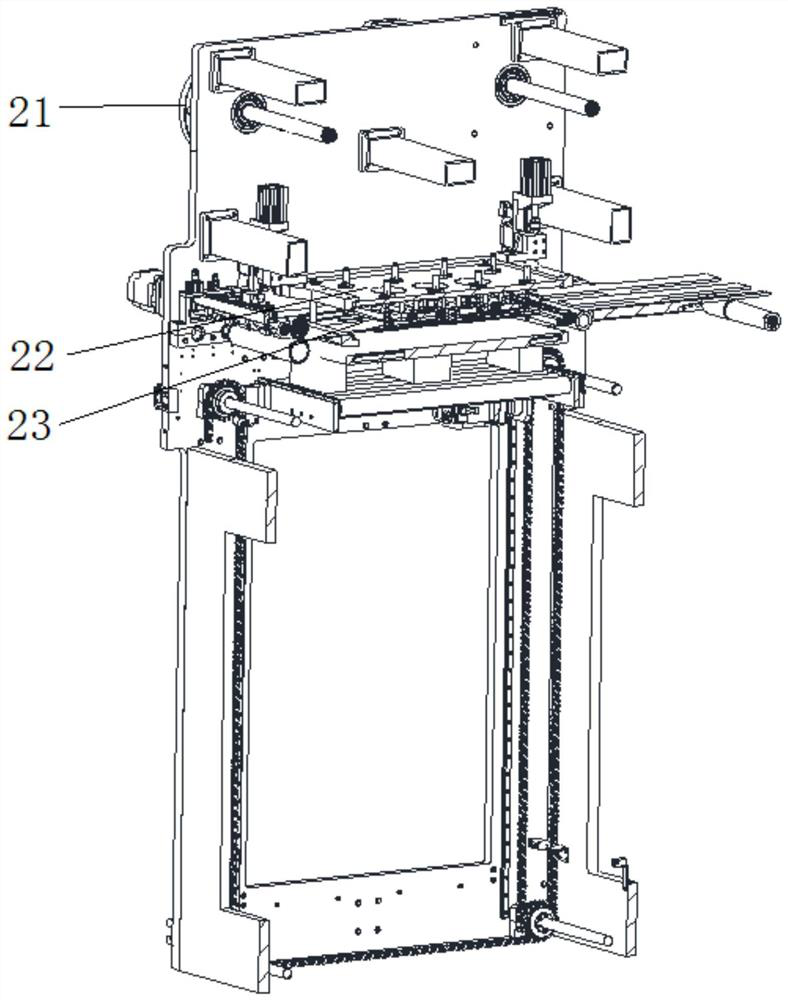

[0027] A waste removal device for unwinding die-cutting machine, such as figure 1 As shown, it includes the semi-cleaning mechanism 1, the full-cleaning mechanism 2, and the paper and waste edge driving mechanism 3. The products after die-cutting are firstly cleaned by semi-cleaning waste edges and small clip edges around the product, and then fully cleaned. For waste treatment, the full cleaning mechanism processes the waste edges inside the product, and the finished products are sent to the automatic stacking and lifting unit at the lower part of the full cleaning mechanism, where they are stacked, and the waste edges are sent to the rear end for processing.

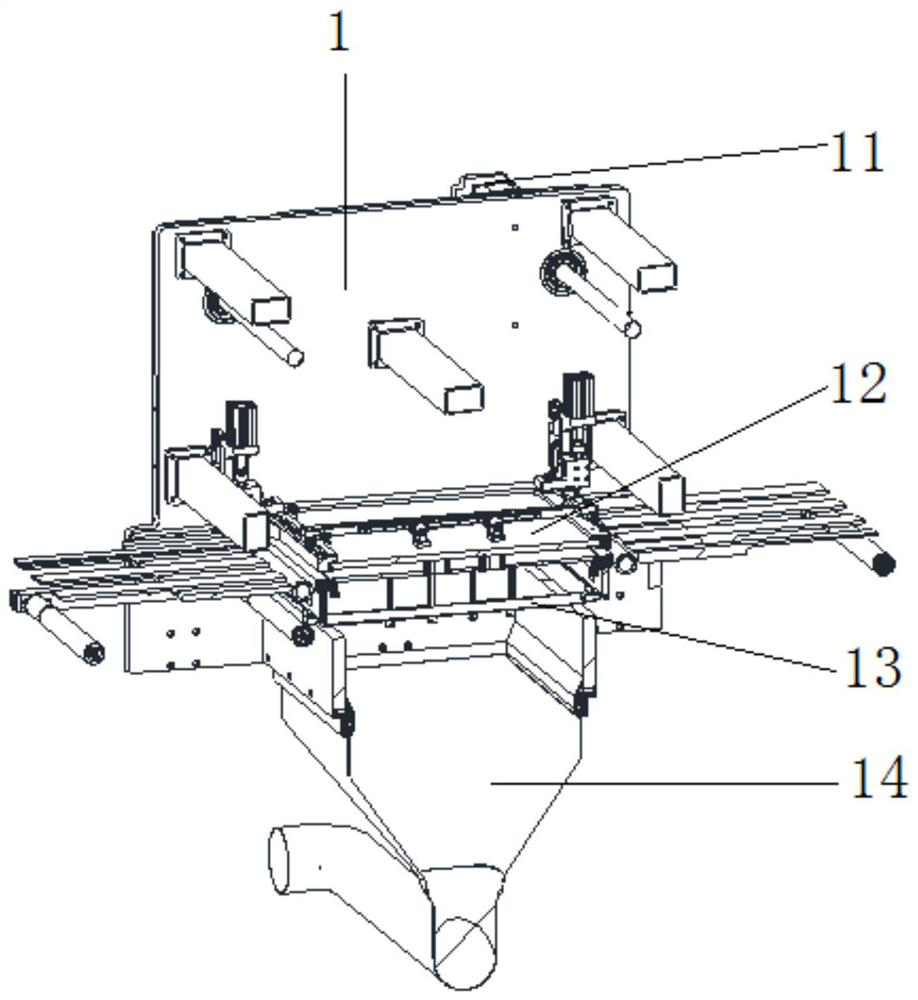

[0028] like figure 2 As shown, the semi-strip mechanism 1 is used to peel off the die-cut product and its peripheral waste edge, including the semi-strip upper template 12 and the semi-striped lower template 13, and the semi-striped upper template 12 is connected to the semi-striped cam drive The unit 11 moves up and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com