Mechanical arm capable of automatically being closed

An automatic closing and manipulator technology, applied in the field of manipulators, can solve the problems that the safety of employees who shuttle between machines cannot be guaranteed, the production cost cannot be reduced, and the parts to be processed fall off. The effect of preventing parts from falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

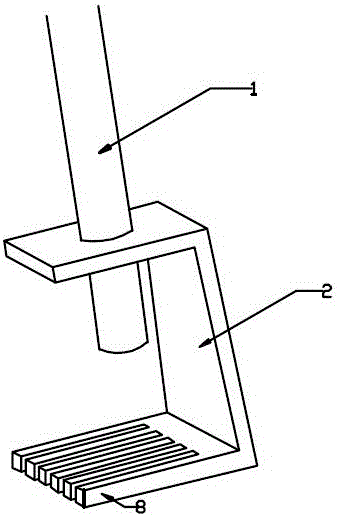

[0021] Such as figure 1 As shown, an automatically closed manipulator includes a fixed rod, a mechanical claw 2, a one-way door structure 9; the mechanical claw 2 is U-shaped; the one-way door structure 9 includes a slider 4, a spring 5, and a spring block 6;

[0022] Such as figure 1 As shown, the mechanical claw 2 includes an upper half, a bend 3 and a lower half; the upper half is provided with a circular hole, the upper half is sleeved on the fixed rod 1 through the circular hole, and the upper half is fixedly connected to the fixed rod 1;

[0023] The top of the bend 3 is fixedly connected to the upper half, and the bottom of the bend is fixedly connected to the lower half;

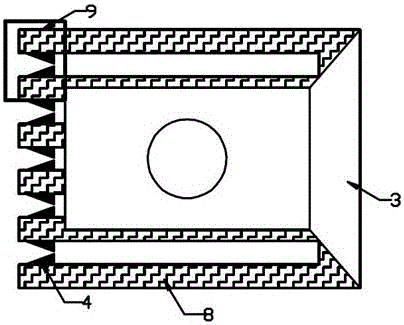

[0024] Such as figure 2 As shown, the lower half is provided with five equally spaced long holes to divide the lower half into six grid blocks 8. Each long hole is provided with two one-way door structures 9, the leftmost and the most The width of the two grid blocks on the right is less than or equal to t...

Embodiment 2

[0029] A mechanical hand that can be closed automatically, comprising a fixed rod, a mechanical claw 2, a one-way door structure 9; the mechanical claw 2 is U-shaped; the one-way door structure 9 includes a slider 4, a spring 5 and a spring block 6;

[0030] The mechanical claw 2 includes an upper half, a bending 3 and a lower half; the upper half is provided with a circular hole, the upper half is sleeved on the fixed rod 1 through the circular hole, and the upper half is fixedly connected to the fixed rod 1, and bent 3 The top part is fixedly connected to the upper body, and the bent bottom part is fixedly connected to the lower body;

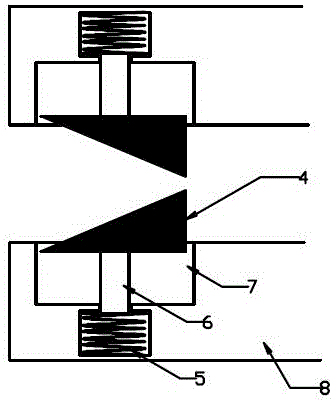

[0031] Such as Figure 4 As shown, the lower half is provided with five equally spaced long holes to divide the lower half into six grid blocks 8. The size of the six grid blocks 8 is equal, and each grid block 8 is provided with a single Toward the door structure 9, such as Figure 5 As shown, a groove 7 is opened on the end of the grid block 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com