Artistic bed

A technology of art and bed legs, applied in the field of art beds, can solve the problems of low production efficiency, high production cost, and fixation, and achieve the effect of high production efficiency and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention are described in detail below in conjunction with the accompanying drawings:

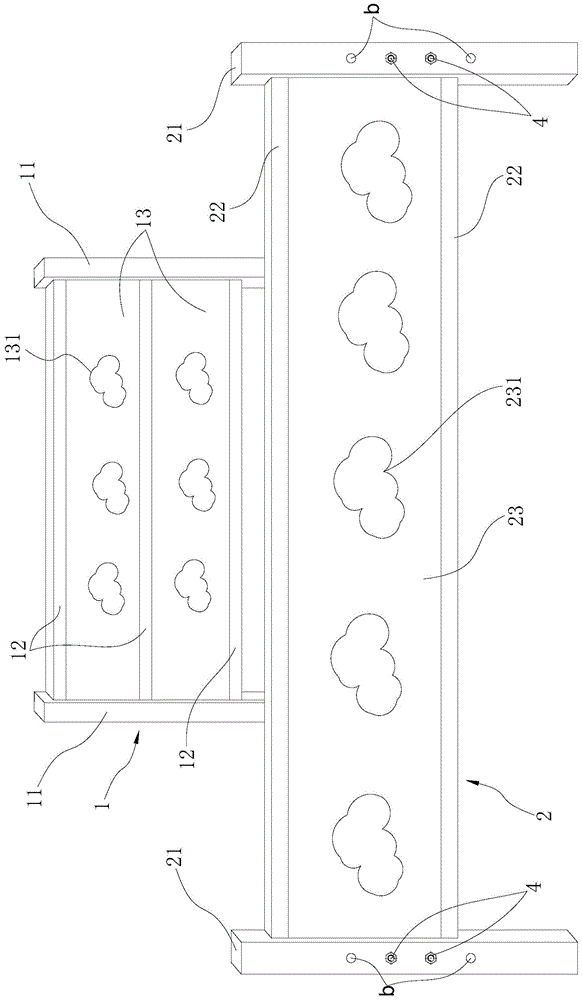

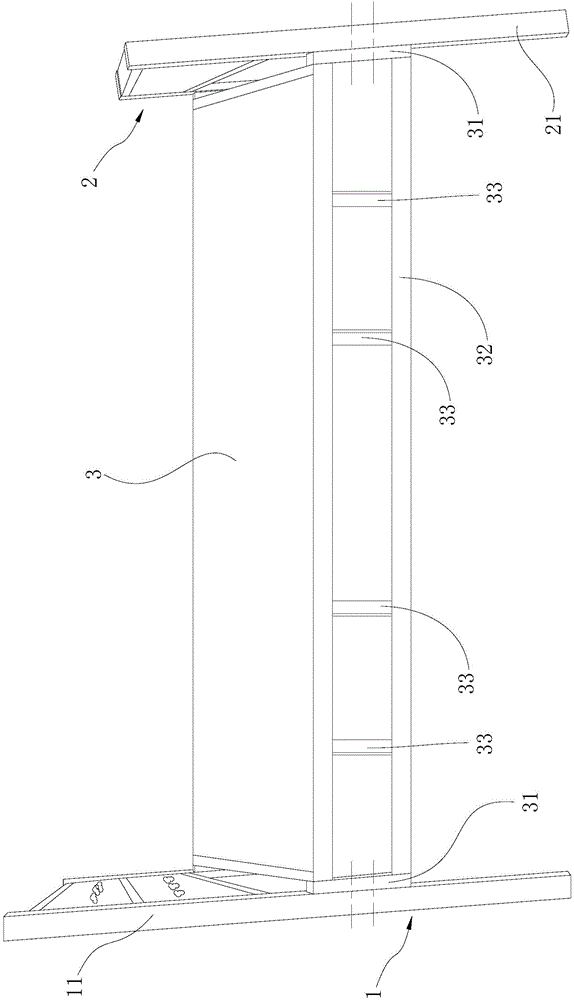

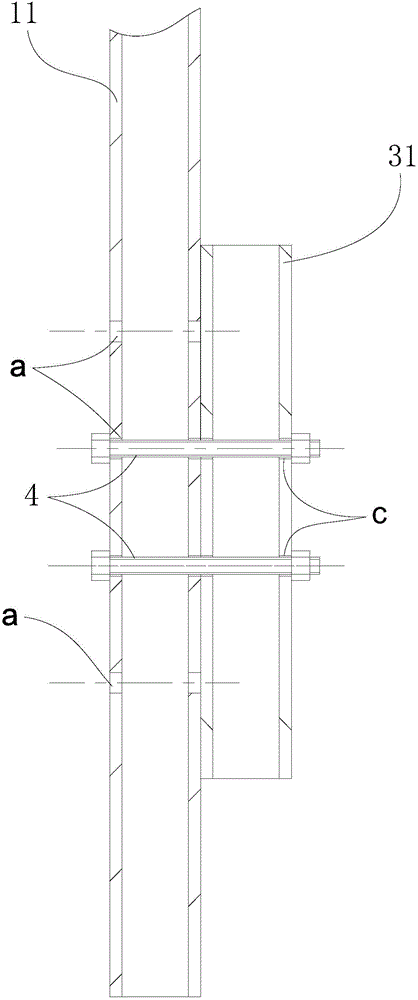

[0030] see figure 1 — Figure 4 :

[0031] An art bed, comprising a bed head 1, a bed end 2, and a horizontally arranged square bed board 3;

[0032] The head of a bed 1 comprises two vertically arranged first bed legs 11, three horizontally arranged backrest bars 12, and two vertically arranged backrest boards 13. Between the upper parts of the first bed legs 11, two first placement cavities are formed between the back bar 12 and the two first bed legs 11, and each first placement cavity is provided with a backrest board 13 by welding; The backboard 13 has a background painting layer 131 near the inner side of the bed board 3, and the pattern on the background painting layer is spray-painted on the backboard 13 after being processed on the computer;

[0033] The end of the bed 2 comprises two vertically arranged second bed legs 21, two horizontally ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com