Air rectification cap deep drawing die with deep drawing beads

An air rectification and deep drawing die technology, applied in the field of mechanical processing and stamping, can solve the problems of uneven wrinkle parts, inability to stretch and form, and wrinkle, etc., and achieve the effects of significant economic benefits, quality assurance, and high technical value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

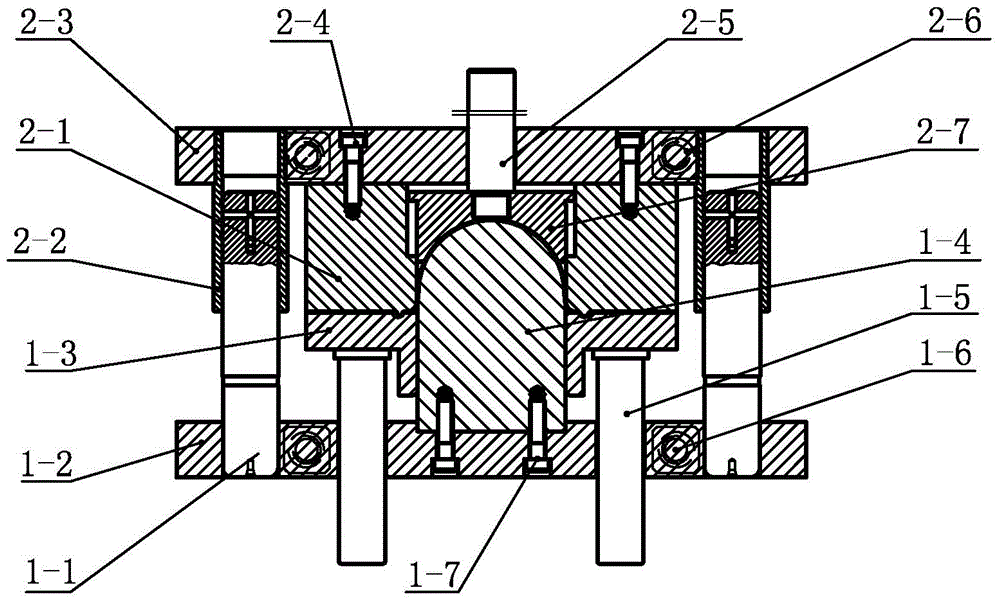

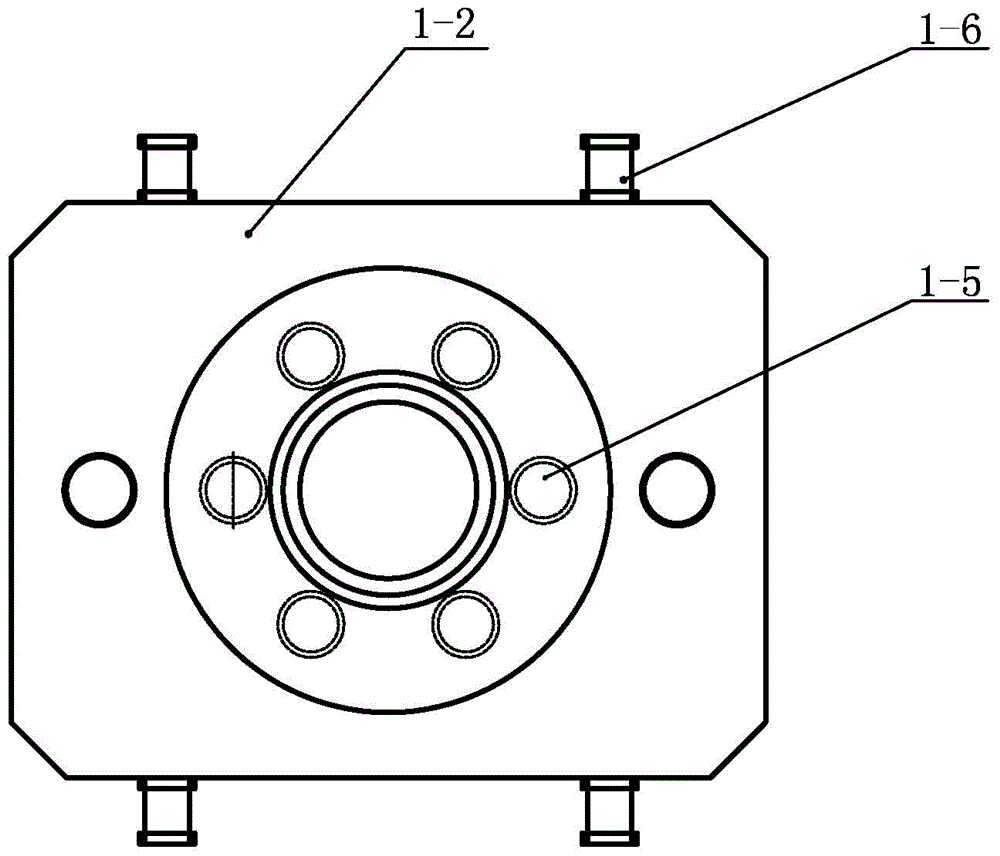

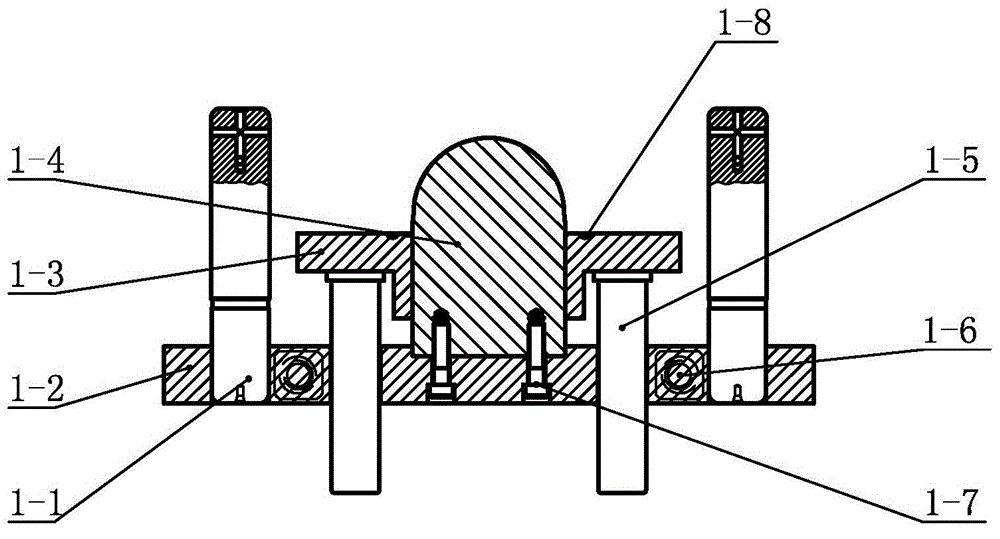

[0011] Specific implementation mode one: combine Figure 1 to Figure 10 Illustrate this embodiment, a kind of air fairing cap drawing mold that has drawing bead of this embodiment, comprises upper mold assembly and lower mold assembly; Said lower mold assembly includes lower mold base 1-2, press Side ring 1-3, punch 1-4, two guide pillars 1-1, four lower die rings 1-6 and at least four blank-holding ejector pins 1-5; Two guide post fixing holes are arranged symmetrically with respect to the vertical center line, the lower ends of the two guide posts 1-1 are fixed in the two guide post fixing holes of the lower mold base 1-2, and the punch 1-4 (through a screw one 1-7) It is connected with the middle part of the upper surface of the lower die base 1-2; the blank holder ring 1-3 is set outside the punch 1-4, and the blank holder ring 1-3 is slidingly matched with the punch 1-4 (binder ring 1-3 can slide up and down along the punch 1-4); the two opposite side walls of the lower ...

specific Embodiment approach 2

[0013] Specific implementation mode two: combination Figure 1 to Figure 4 Explain that the lower mold base 1-2 described in this embodiment is provided with six ejector pin penetration holes, and the six ejector pin penetration holes are evenly distributed on the same circumference, and the center of the circumference is the same as the lower mold base 1-2. The center is concentric. Good processing stability. The undisclosed technical features in this embodiment are the same as those in the specific embodiment.

[0014] The working principle of the present invention is:

[0015] The guide column 1-1 is fixed on the working table of the equipment along with the lower mold assembly, and the upper mold guide sleeve 2-2 is fixed on the upper slider of the equipment along with the upper mold assembly. After the mold is connected to the equipment, start the equipment Make the upper slider of the equipment drive the upper die assembly to rise to the upper dead point, start the ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com