Automatic drilling tool for welding yokes

A technology for drilling tooling and welding forks, which is applied in the directions of driving devices, boring/drilling, drilling/drilling equipment, etc. Hole efficiency and processing accuracy are improved, and the effect of automatic processing operation is realized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

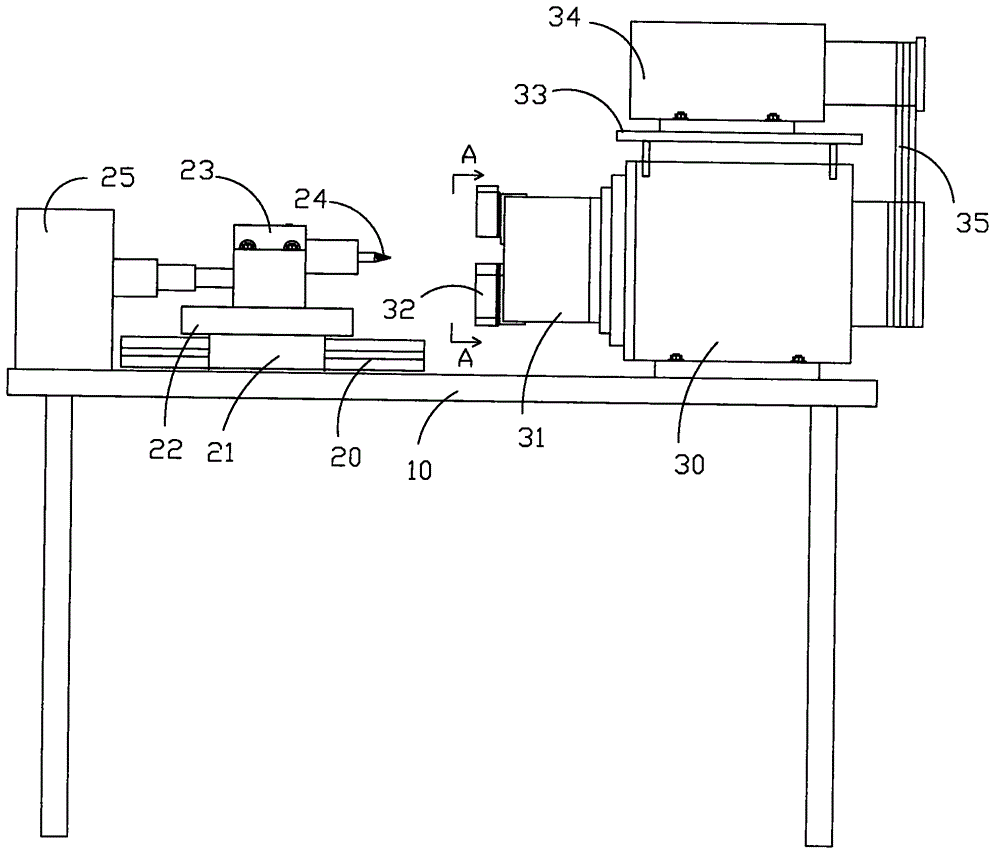

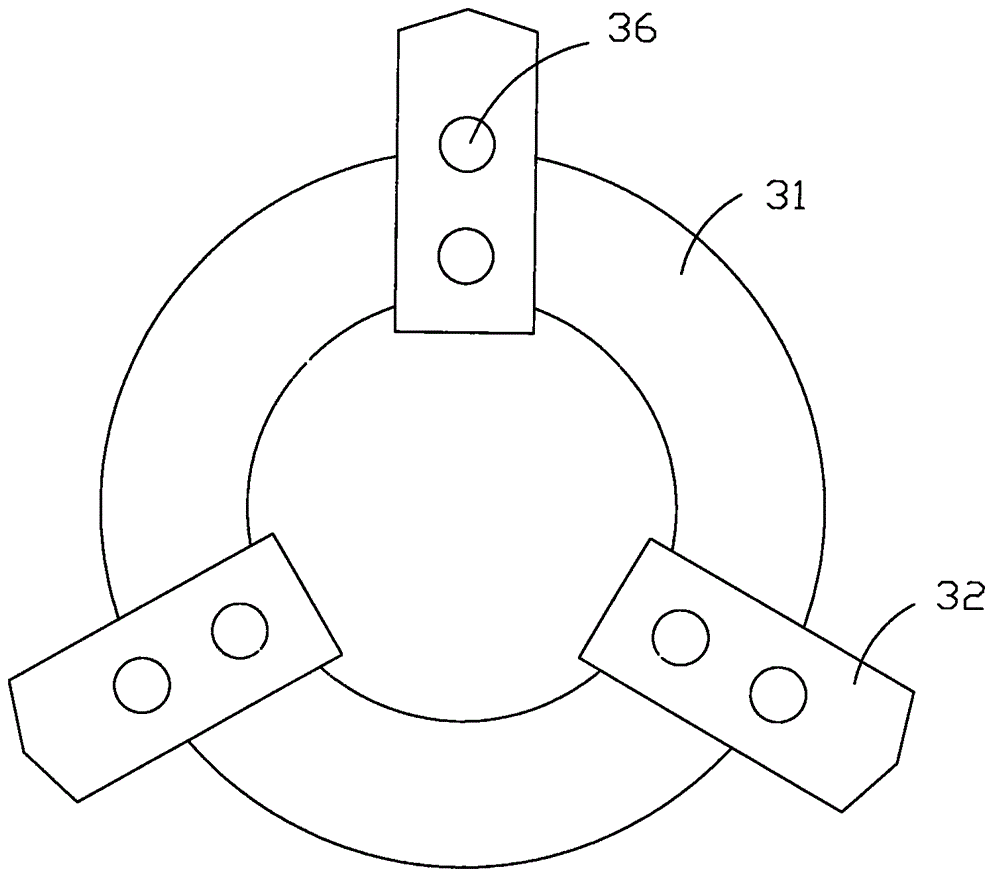

[0016] In order to further describe the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. Figure 1-3 Shown is a welding fork automatic drilling tool, which is arranged on the console 10, and includes workpiece clamping and rotating parts and drill bit fixing and advancing parts, wherein:

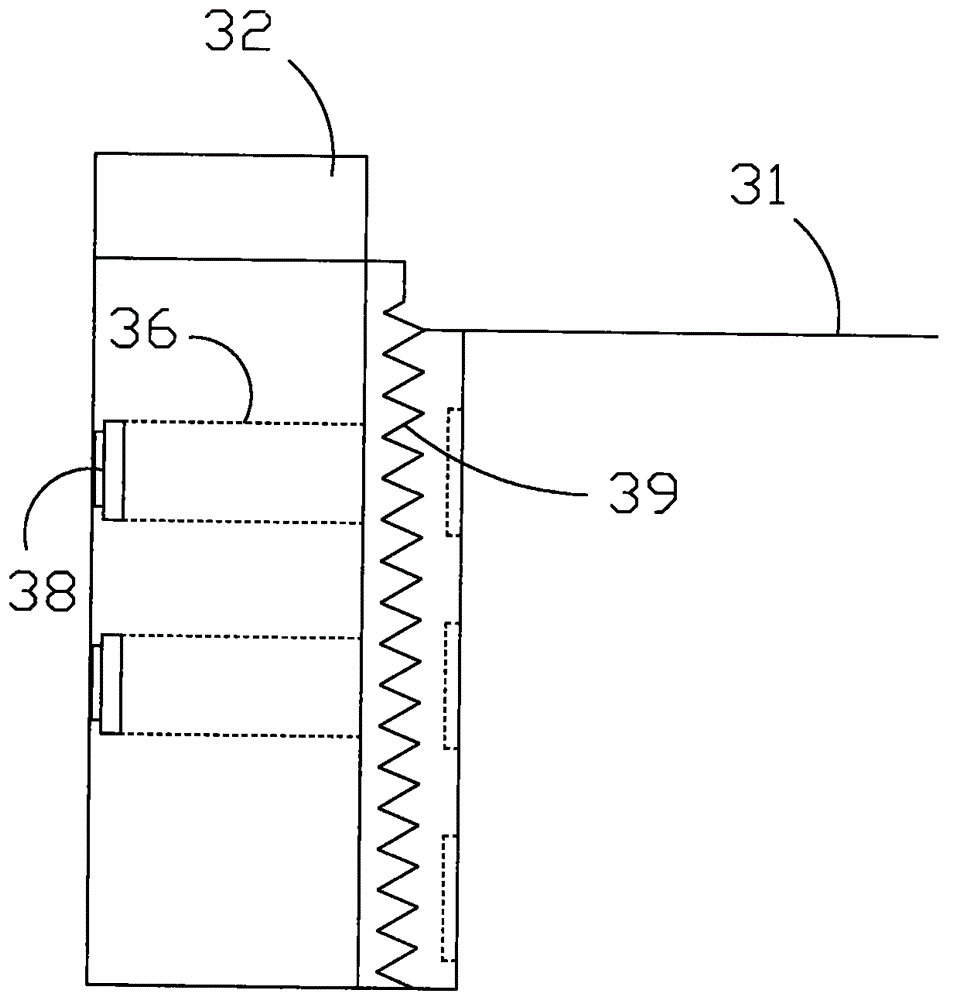

[0017] The workpiece clamping and rotating components include a shaft coupling 30 placed on the console 10, a drive motor 34 connected to the shaft coupling 30 through a belt set 35 and placed on the top of the shaft coupling 30, and a transmission shaft of the shaft coupling 30 An end portion of the chuck 31 is provided with a set of workpiece holding blocks 32 .

[0018] The drill fixing and propulsion components include a guide rail 20 placed on the console 10, a slider 21 sleeved on the guide rail 20, a base 22 placed on the slider 21, and a drill clamp placed on the top of the base 22. Bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com