A kind of processing equipment and processing method of power distribution control cabinet board

A technology of power distribution control and processing equipment, which is applied in the direction of metal processing, can solve the problems of troublesome operation and laborious operation, and achieve the effect of automatic processing operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

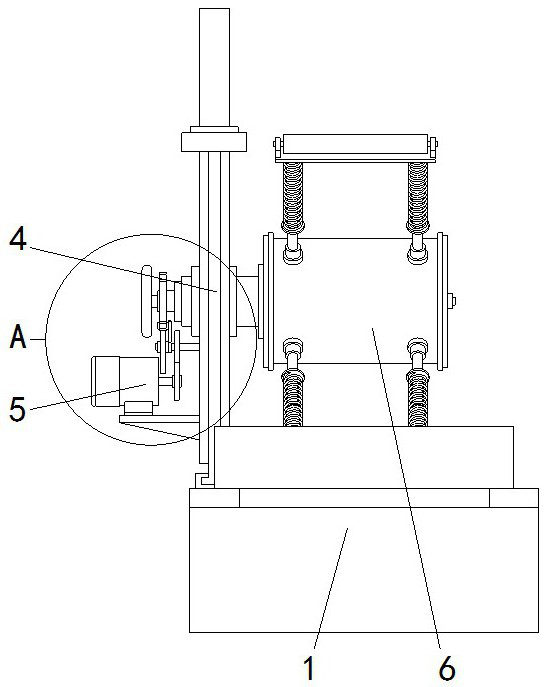

[0036] Further below with reference to the accompanying drawings of the detailed description of the technical solution of the present invention.

[0037] See Figure 1-8As shown, a power distribution control cabinet processing apparatus includes a cutting table 1, a discharge mechanism 2, a horizontal adjusting mechanism 3, a lifting regulating mechanism 4, a batch rotating mechanism 5, and a fixed length conveying mechanism 6, a cutting table 1 The on-side bonnet 11 is opened in the position close to one side, and the cutting table 1 is provided with a vertical baffle 12 on the opening position close to the avoidance frame 11, and the discharge mechanism 2 is disposed at an affordable frame 11. The discharge mechanism 2 includes a downwardly flipped unloading plate 24, and when the unloading plate 24 is horizontal, the upper end surface of the discharge plate 24 is flush, and the horizontal adjustment mechanism 3 is disposed at the cutting table 1. On the table, the lift adjustmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com