Tool for auxiliary adjustment of automatic welding tungsten electrode inclined angle

An inclination angle, automatic welding technology, applied in welding accessories and other directions, can solve the problem of inability to accurately adjust the inclination angle of automatic welding tungsten electrodes, and achieve the effect of improving welding quality and accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

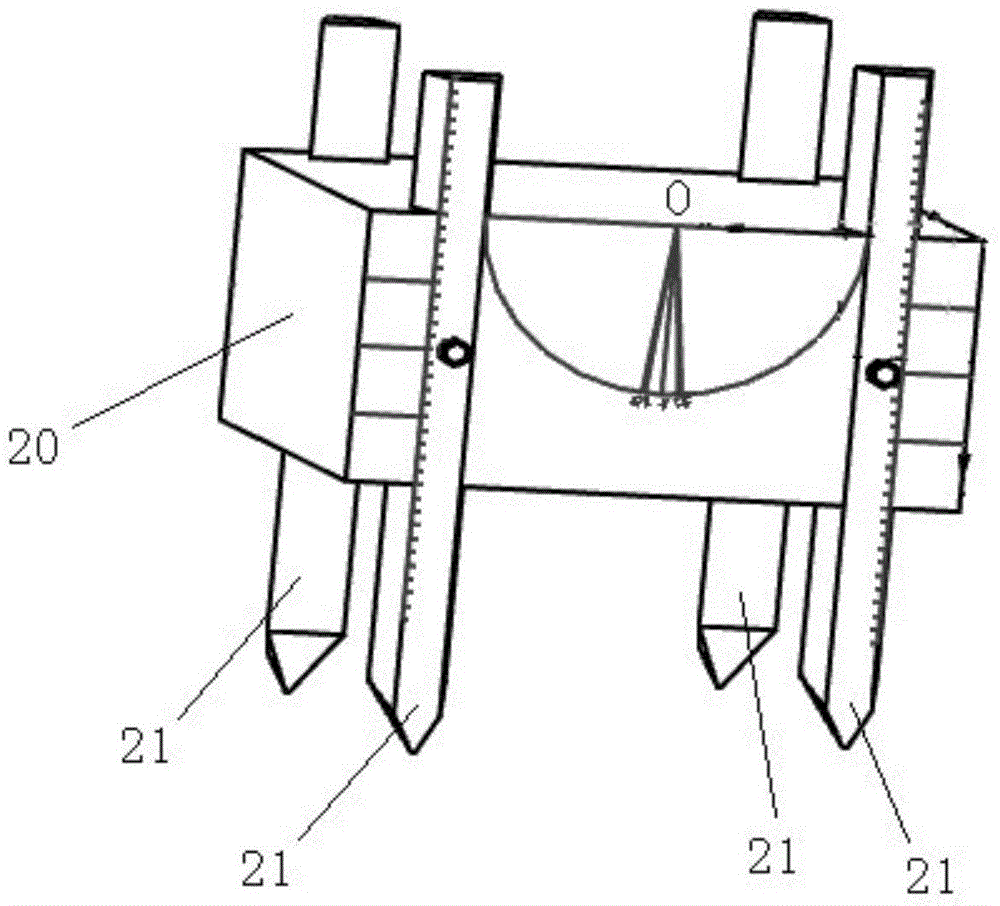

[0024] Combine below Figure 3-Figure 6 The tool of the present invention is introduced.

[0025] Such as image 3 As shown, the tool for assisting in adjusting the inclination angle of the automatic welding tungsten electrode of the present invention includes a body 20 and four supporting legs 21 . The main body 20 is a rectangular body structure, two opposite sides of the main body 20 are respectively provided with two grooves, and the four support legs 21 are respectively fixed in the grooves of the main body 20 by bolts for supporting the main body 20; Several threaded holes are arranged in the groove, so that the supporting legs 21 can be fixed in different positions in the groove; the supporting legs 21 are marked with length scales. The side of the groove on the body 20 is marked with an angle scale, because the range of the horizontal inclination angle of the automatic welding tungsten electrode is -6°-6°, and the angle range of the longitudinal inclination is 0°-6°,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com