A kind of automatic rolling equipment for automobile door strips

A kind of equipment and automatic technology, applied in the direction of metal processing equipment, vehicle parts, material gluing, etc., can solve the problems of rolling force reliability and uniformity difference, affecting the production efficiency and product quality of automobile assembly line, etc., to achieve high flexibility and avoid The effect of unstable heating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

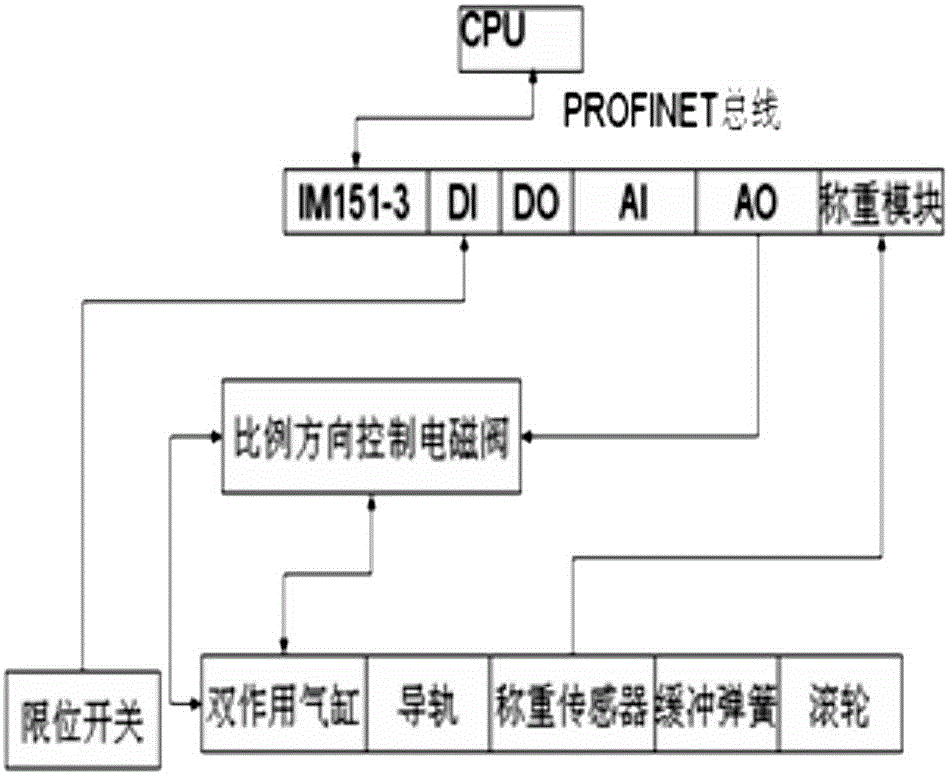

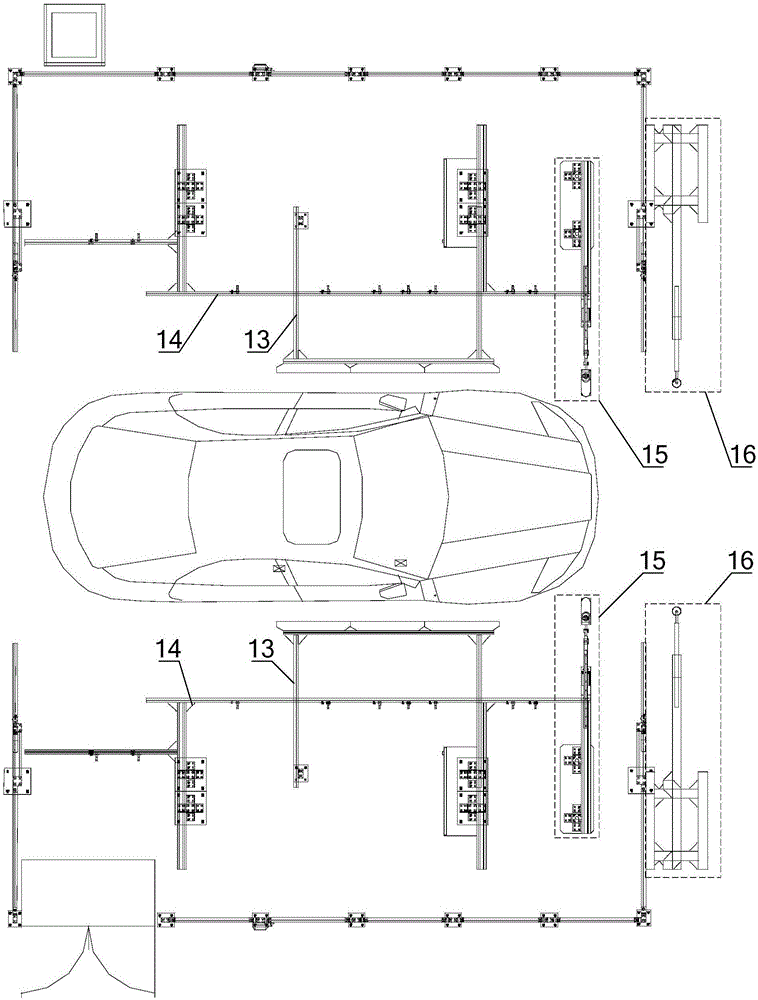

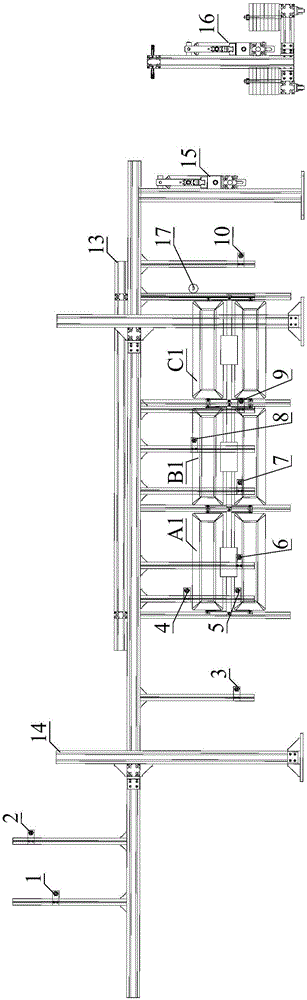

[0034] See attached figure 1 , attached figure 2 And attached Figure 10 , a kind of automatic rolling equipment for automobile door strips of the present invention includes an equipment outer frame and a fully automatic rolling equipment; Recognition unit, car position recognition unit, heat radiation unit, automatic rolling mechanical unit 15 and control cabinet; the car is transported to the inside of the basic support through an automatic conveyor chain, and the vehicle type recognition unit and car position recognition unit are respectively used to identify the vehicle type and judge the position of the body , when the position of the door strip passes through the heat radiation unit, it will be automatically heated by the heat radiation unit to ensure the temperature requirements of the bonding process. When the door strip of the body reaches th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com