A globe production device with an automatic milling cutter device

A technology of production equipment and globes, applied in the direction of manufacturing tools, wood processing equipment, special molding/shaping machines, etc., can solve the problems of health impact, labor and time consumption, and environmental protection, and achieve less harmful substances and convenient use , the effect of warm appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

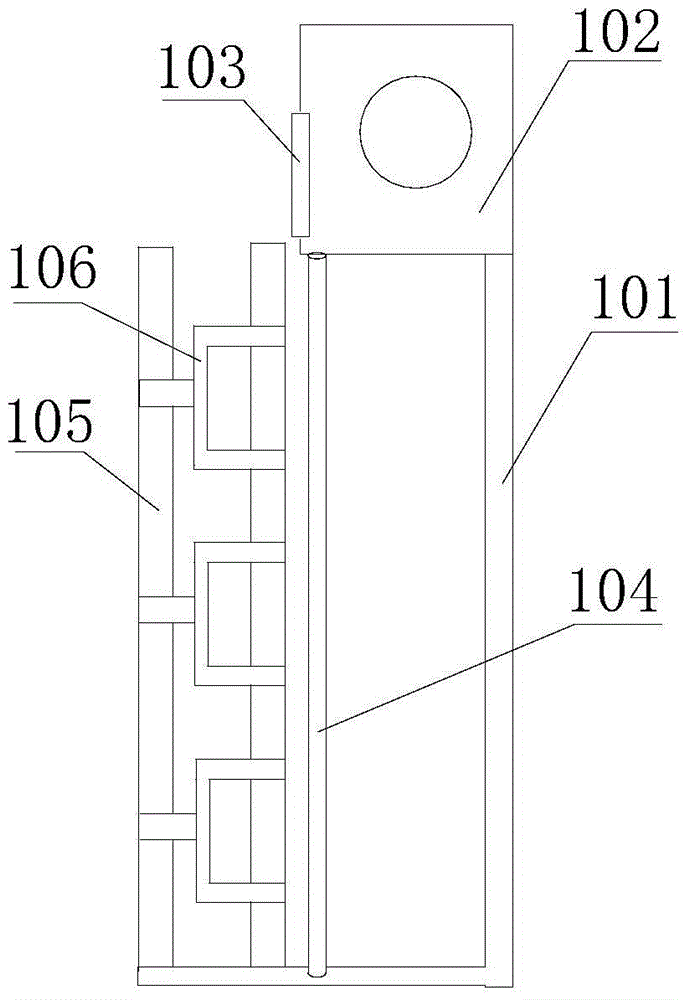

[0021] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

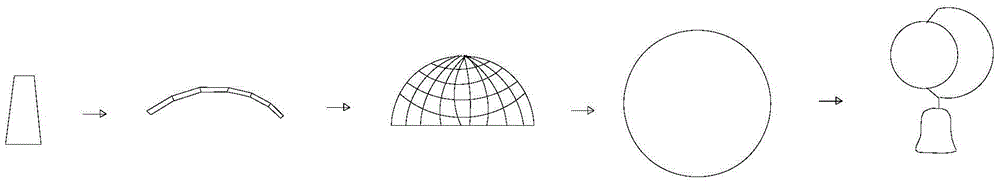

[0022] Such as figure 1 Shown, the manufacturing method of the globe that present embodiment comprises, comprises the following steps:

[0023] (1) cutting board

[0024] Cut the flat plate into 288 isosceles trapezoidal saw petals of different sizes. The angle between the two waistlines of the isosceles trapezoid is 7-10°. Cracking and deformation, high wear resistance, warm appearance, bright color;

[0025] (2) button flap

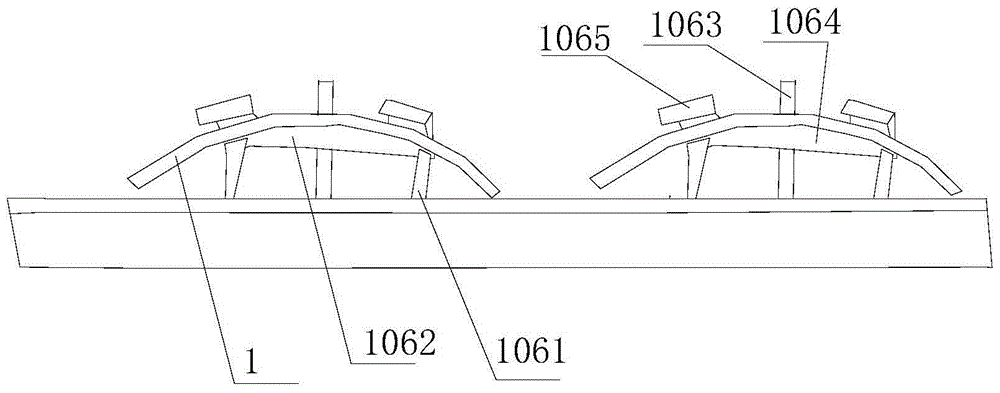

[0026] Glue a meridian on the hemisphere with at least five saw blades in turn to form saw blade arc 1, along the hemisphere apex to the equator of the hemisphere, the center line of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com