An installation structure of a heat sink and a front-end module

A front-end module and installation structure technology, which is applied in the field of radiator and front-end module installation structure, can solve the problems of unfavorable front-end module strength, complex structure, heavy weight, etc., and achieve the effect of light weight, firm clamping and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are only used to explain the present invention, and do not constitute a limitation to the protection scope of the present invention.

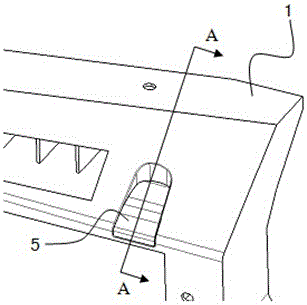

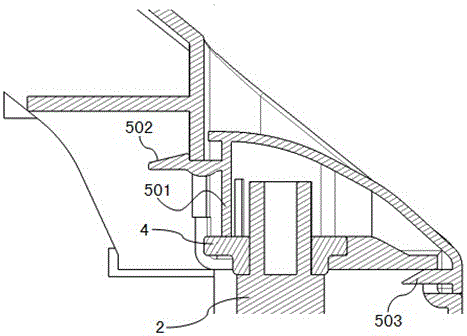

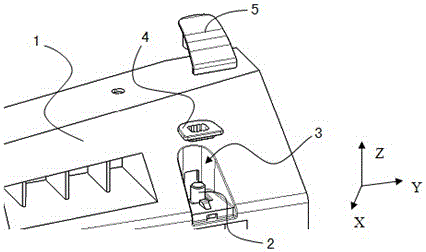

[0019] Such as figure 1 , figure 2 , image 3 The shown installation structure of the radiator and the front-end module includes the front-end module 1 and the radiator, and the radiator has an upwardly protruding mounting post 2 .

[0020] The front-end module is recessed to form an installation platform 3, and the installation platform is surrounded by a bottom surface 301 and a side wall 302, and the side wall is U-shaped, so that the upper part and the front end of the installation platform are open.

[0021] A connection hole 303 is opened in the installation platform, and the installation column 2 passes through the connection hole, and a positioning ring 4 is set on the installation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com