Advanced treatment system and process of chemical wastewater

A technology for the advanced treatment of chemical wastewater, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. It can solve the problems of high chemical consumption, toxic and harmful substances, and poor biodegradability of wastewater and other problems, to achieve the effect of convenient and reliable use, low cost, and improved biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

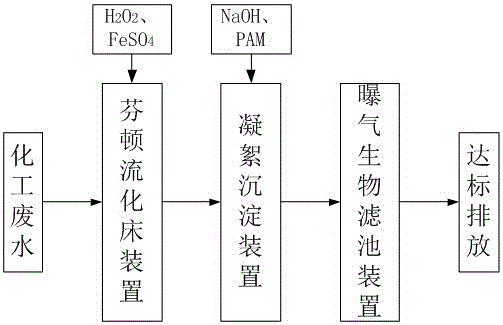

[0041] Such as figure 1 As shown, the advanced treatment system of the chemical wastewater includes a Fenton fluidized bed device, a flocculation sedimentation device and a biological aerated filter device connected in sequence.

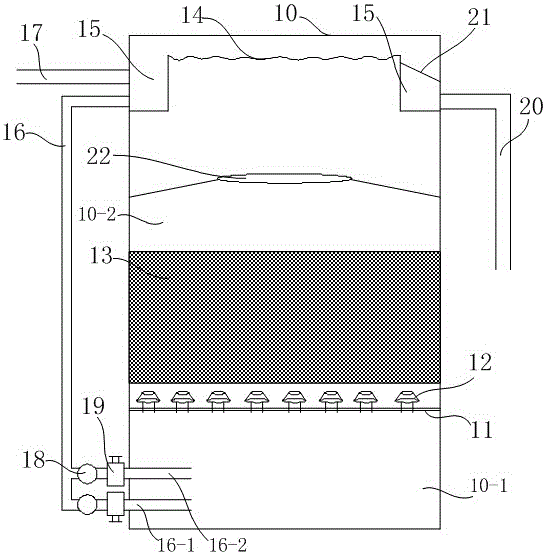

[0042] Such as figure 2 As shown, specifically, the Fenton fluidized bed device includes a reaction tank 10, which is arranged at the lower part of the reaction tank and is divided into a pre-mixing chamber 10-1 below and an upper reaction chamber 10-2. Plate 11, several water distributors 12 installed on the partition and connected to the pre-mixing chamber and the reaction chamber, the granular catalyst filler 13 filled in the lower part of the reaction chamber, arranged on the upper part of the reaction chamber and connected to the inner wall of the reaction tank The outlet weir plate 14 is fixedly connected to form two overflow tanks 15, one end communicates with one overflow tank and the other end communicates with the first outlet pipe 20 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com