Manhole cover blind hole lift

A technology for manhole covers and blind holes, which is applied in the field of lifting devices for blind holes of manhole covers, can solve problems such as dust, cigarette butts entering, underground engineering maintenance troubles, fork heels stuck in, etc., to achieve convenient procurement and high service life , to avoid the effect of slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

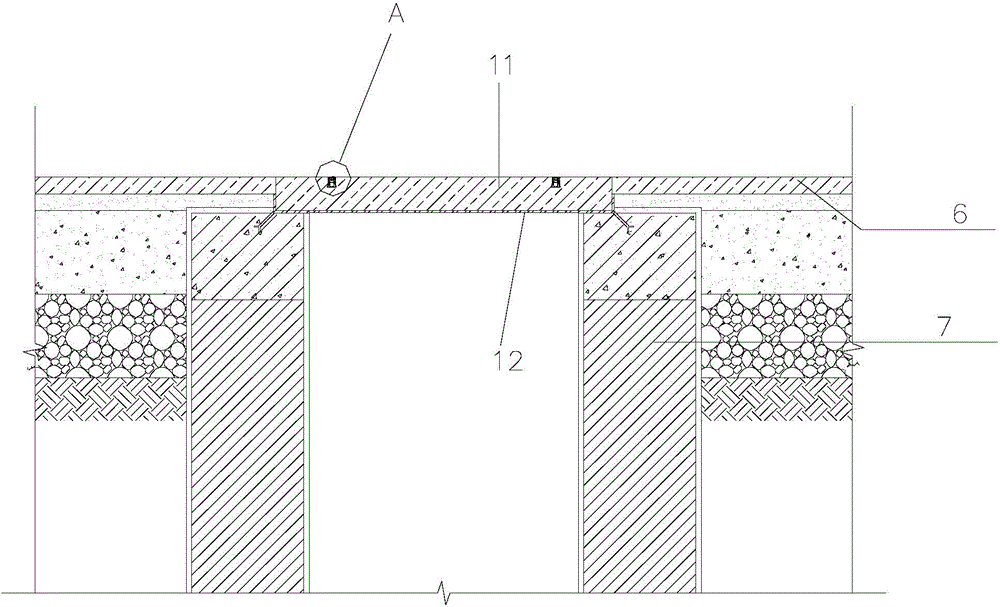

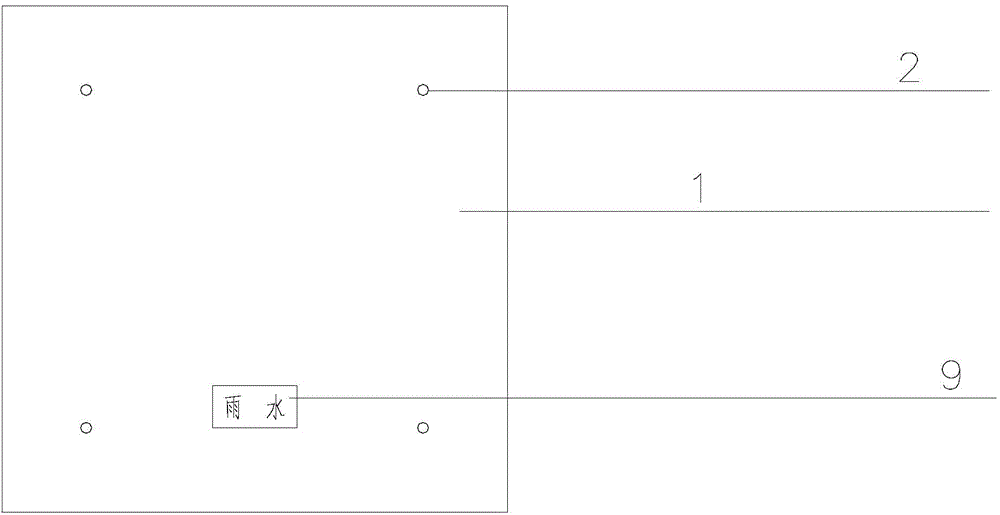

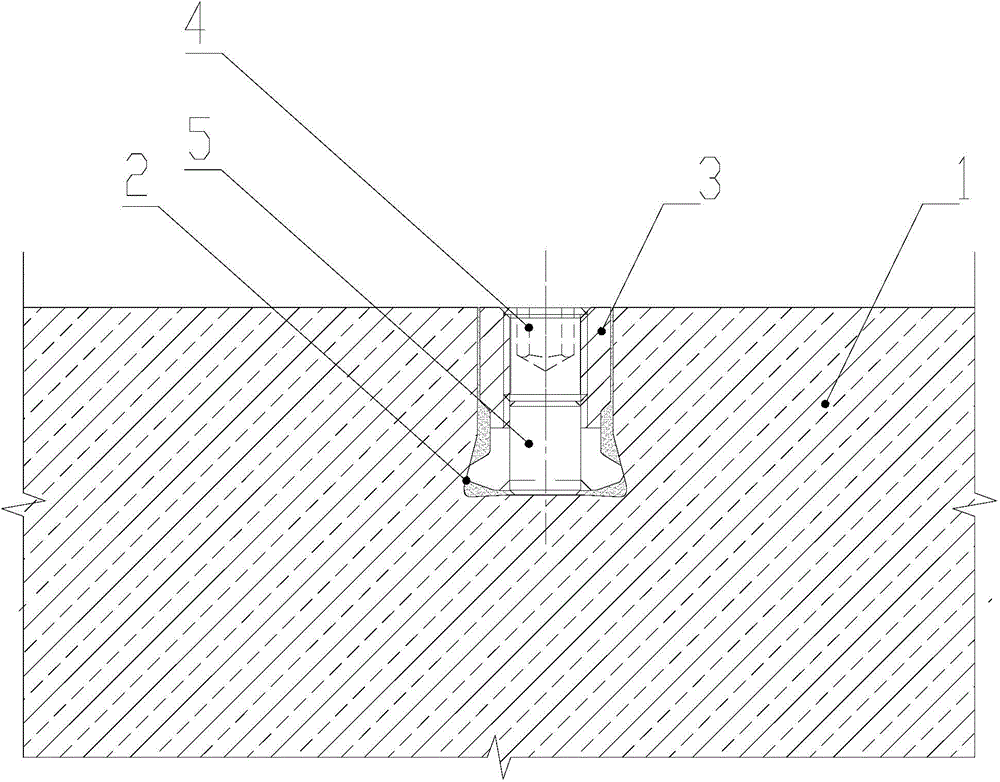

[0029] Example: Figure 1 ~ Figure 4 It is a structural schematic diagram of a blind hole lifting device for a manhole cover. The lifting device includes four back bolt holes 2 with a diameter of 13mm opened on the upper surface of the manhole cover plate 1, and these four back bolt holes 2 are distributed in a rectangular shape. An internally threaded blind hole anchor bolt 3 with an M8 threaded hole 32 is anchored in the back bolt hole 2, and the blind hole anchor bolt 3 described in this example is through The steel cylinder 5 is anchored in the back bolt hole 2. An M8*9 hexagon socket set screw 4 is threaded in the M8 threaded hole of the blind hole anchor bolt 3 . The hexagon socket set screw 4 is used to protect the thread of the M8 threaded hole.

[0030] It should be noted that the diameter of the back bolt hole 2, the size of the threaded hole 32 in the blind anchor bolt 3, the size of the hexagon socket set screw 4, and the number of the back bolt holes 2 can be s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com