Interlocking and gear pushing mechanical anti-theft lock

A technology of mechanical anti-theft locks and additional teeth, applied in the field of anti-theft locks, can solve the problems of no interlocking and self-locking anti-theft locks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

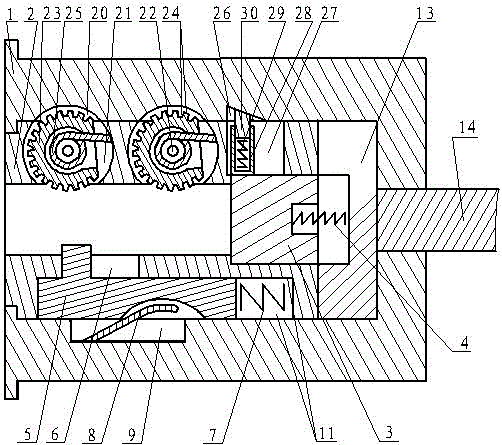

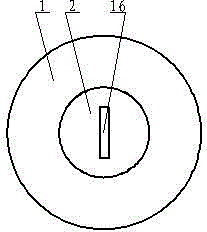

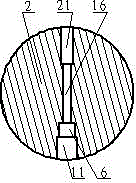

[0069] The interlocking additional tooth push mechanical anti-theft lock of the present invention mainly includes a lock body 1, a front lock core 2, a rear lock core 13, a connecting body 3, a return spring 4, a turning groove 6, a sliding groove 11, a sliding block 5, and a locking groove 10. Expansion groove 9, expansion piece 8, sliding push spring 7, connection hole 12, connection tongue 14, spring bearing hole 15, special key hole 16, special key, rotation hole 21, turn lock groove 20, gear wheel 23. Shaft turning pin 22, clockwork spring 25, horizontal hole 27, longitudinal lock groove 26, locking seat 28, lock cylinder 30, push spring 29;

[0070] A front lock cylinder 2 and a rear lock cylinder 13 are installed in the lock body 1, and the rear lock cylinder 13 is movably installed on the rear end of the front lock cylinder 2, completely disconnected from the front lock cylinder 2; 2, there are turning grooves 6, sliding grooves 11, turning holes 21, horizontal holes 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com